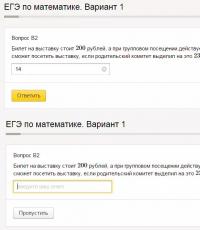

Presentation: Steam turbines as the main engine in thermal power plants. Physics presentation on the topic of turbines Presentation for the lesson - symbols of steam turbines

Essay

on the topic of:

"Steam turbines as the main engine in thermal power plants"

History of the development of steam turbines

Let's imagine a closed metal vessel (boiler) partially filled with water. If you light a fire under it, the water will begin to heat up and then boil, turning into steam. The pressure inside the boiler will increase, and if its walls are not strong enough, it may even explode. This shows that the pair has accumulated a reserve of energy, which finally manifests itself in an explosion. Is it possible to force steam to do any useful work? This question has occupied scientists for a very long time. The history of science and technology knows many interesting inventions in which man sought to use steam energy. Some of these inventions were useful, others were just clever toys, but at least two inventions must be called great; they characterize entire eras in the development of science and technology. These great inventions are the steam engine and the steam turbine. The steam engine, which received industrial use in the second half of the 18th century, revolutionized technology. It quickly became the main engine used in industry and transport. But at the end of the 19th and beginning of the 20th centuries. the achievable power and speed of the steam engine had already become insufficient.

There is an urgent need for the construction of large power stations, for which a powerful and high-speed engine was needed. Such an engine was the steam turbine, which can be built to produce enormous power at high speeds. The steam turbine quickly replaced the steam engine from power plants and large steamships.

The history of the creation and improvement of the steam turbine, like any major invention, is associated with the names of many people. Moreover, as is usually the case, the basic operating principle of the turbine was known long before the level of science and technology allowed the construction of a turbine.

The principle of operation of a steam engine is to use the elastic properties of steam. Steam periodically enters the cylinder and, expanding, does work by moving the piston. The operating principle of a steam turbine is different. Here the steam expands, and the potential energy accumulated in the boiler is converted into high-speed (kinetic) energy. In turn, the kinetic energy of the steam jet is converted into mechanical energy of rotation of the turbine wheel.

The history of turbine development begins with the ball of Heron of Alexandria and the Branca wheel. Possibility of using steam energy to produce mechanical movement was noted by the famous Greek scientist Heron of Alexandria more than 2000 years ago. He built a device called Heron's ball (Fig. 1).

The ball could rotate freely in two supports made of tubes. Through these supports, steam from the boiler entered the ball and then exited into the atmosphere through two tubes bent at right angles. The ball rotated under the action of reactive forces arising from the flow of steam jets.

Another project is described in the work of the Italian scientist Giovani Branca (1629). A tube is inserted into the upper part of the boiler (Fig. 2).

Since the steam pressure inside the boiler is greater than the atmospheric pressure of the air around the boiler, the steam rushes out through the tube.

A stream of steam shoots out from the free end of the tube and hits the wheel blades, causing it to rotate.

Heron's model and Branca's wheel were not engines, but they already indicated possible ways of obtaining mechanical motion using the energy of the driving steam.

There is a difference in the operating principles of Heron's ball and Branca's wheel. Heron's ball, as already mentioned, rotates under the action of reactive forces. These are the same forces that push a rocket. It is known from mechanics that a jet pushed out of a vessel under the influence of pressure, for its part, presses on the vessel in the direction opposite to the direction of outflow. This is obvious based on Newton's third law, according to which the force pushing out the jet must be equal and opposite in direction to the reaction force of the jet on the vessel.

In the Branca turbine, the potential energy of the steam is first converted into the kinetic energy of the jet gushing from the tube. Then, when the jet hits the wheel blade, part of the kinetic energy of the steam is converted into mechanical energy of rotation of the wheel.

If Heron's ball moves by reactive forces, then the Branca turbine uses the so-called active principle, since the wheel draws energy from the active jet.

The greatest shift in the design of the steam turbine and its further development occurred at the end of the century before last, when in Sweden engineer. Gustav Laval and in England Charles Parsons independently began to work on the creation and improvement of the steam turbine. The results they achieved allowed the steam turbine to eventually become the main type of engine for driving electric current generators and obtain wide application as an engine for civil and military ships. In the Laval steam turbine, created in 1883, steam enters one or more parallel-connected nozzles, acquires a significant speed in them and is directed to working blades located on the rim of a disk sitting on the turbine shaft and forming a lattice of working channels.

The forces caused by the rotation of the steam jet in the channels of the working grid rotate the disk and the turbine shaft associated with it. Distinctive feature of this turbine is that the expansion of steam in the nozzles from the initial to the final pressure occurs in one stage, which causes a very high speeds steam flow. The conversion of the kinetic energy of steam into mechanical energy occurs without further expansion of the steam only due to a change in the direction of flow in the blade channels.

Turbines built on this principle, i.e. turbines in which the entire process of steam expansion and associated acceleration of steam flow occurs in stationary nozzles are called active turbines.

During the development of active single-stage turbines, a number of complex issues were resolved, which were of extremely great importance for the further development of steam turbines. Expanding nozzles were used, which allow a greater degree of steam expansion and allow high steam flow velocities to be achieved (1200–1500 m/sec). To make better use of high steam flow rates, Laval developed a design of an equal-resistance disk that allowed operation at high peripheral speeds (350 m/sec). Finally, in the single-stage active turbine such high speeds were used (up to 32,000 rpm), which far exceeded the speeds of engines common at that time. This led to the invention of a flexible shaft, the frequency of free vibrations of which is less than the frequency of disturbing forces at the operating speed.

Despite a number of new design solutions used in single-stage active turbines, their efficiency was low. In addition, the need to use a gear transmission to reduce the speed of the drive shaft to the level of the speed of the driven machine also hampered the development of single-stage turbines at that time and, in particular, the increase in their power. Therefore, Laval turbines, having received significant popularity at the beginning of the development of turbine construction as low-power units (up to 500 kW), later gave way to other types of turbines.

The steam turbine proposed in 1884 by Parsons is fundamentally different from the Laval turbine. The expansion of steam in it is carried out not in one nozzle group, but in a number of successive stages, each of which consists of stationary guide vanes (nozzle arrays) and rotating blades.

The guide vanes are fixed in the stationary turbine housing, and the rotor blades are arranged in rows on the drum. Each stage of such a turbine experiences a pressure drop that is only a small fraction of the total difference between the fresh steam pressure and the pressure of the steam leaving the turbine. Thus, it was possible to operate with low steam flow velocities in each stage and with lower peripheral speeds of the rotor blades than in the Laval turbine. In addition, the expansion of steam in the stages of a Parsons turbine occurs not only in the nozzle, but also in the working grid. Therefore, forces are transmitted to the working blades caused not only by a change in the direction of steam flow, but also by the acceleration of steam within the working grid, causing a reactive force on the turbine working blades.

Turbine stages in which steam expansion and the associated acceleration of steam flow in the channels of the working blades are used are called reaction stages. Thus, shown in Fig. 4 turbine was a typical representative of multi-stage jet steam turbines.

The principle of sequential inclusion of stages, each of which uses only part of the available thermal difference, turned out to be very fruitful for the subsequent development of steam turbines. It made it possible to achieve high efficiency in the turbine at moderate speeds of the turbine rotor, allowing direct connection of the turbine shaft with the shaft of the electric current generator. The same principle made it possible to manufacture turbines of very high power, reaching several tens and even hundreds of thousands of kilowatts in one unit.

Multistage jet turbines are now widespread, both in stationary installations and in the fleet.

The development of active steam turbines also followed the path of sequential expansion of steam not in one, but in a number of stages located one after another. In these turbines, a number of disks mounted on a common shaft are separated by partitions called diaphragms, in which fixed nozzle grids are located. In each of the stages constructed in this way, the steam expands within a portion of the total available heat loss. In the working grids, only the conversion of the kinetic energy of the steam flow occurs without additional expansion of steam in the channels of the working blades. Active multistage turbines are widely used in stationary installations; they are also used as marine engines.

Along with turbines in which steam moves in the direction of the turbine shaft axis (axial), designs of radial turbines were created in which steam flows in a plane perpendicular to the turbine axis. Of the latter, the most interesting is the radial turbine, proposed in 1912 in Sweden by the Ljungström brothers.

Rice. Schematic drawing of a Jungström radial turbine:

1,2 – turbine disks; 3 – fresh steam lines; 4, 5 – turbine shafts; 6, 7 – blades of intermediate stages

On the side surfaces of disks 1 and 2, the blades of the jet stages are located in rings of gradually increasing diameter. Steam is supplied to the turbine through pipes 3 and then through holes in disks 1 and 2 to the central chamber. From here it flows to the periphery through the channels of the blades 6 and 7, mounted on both disks. Unlike a conventional design, the Jungström turbine does not have fixed nozzle grids or guide vanes. Both disks rotate in counter directions, so the power developed by the turbine must be transmitted by shafts 4 and 5. The principle of counter-rotation of the rotors allows the turbine to be very compact and economical.

PAGE_BREAK--

Since the early 1990s, the development of steam turbines has proceeded at an exceptionally rapid pace. This development was largely determined by the equally rapid parallel development of electric machines and the widespread introduction electrical energy into industry. The efficiency of a steam turbine and its power in one unit have reached high values. The power of the turbines far exceeded the power of all other types of engines without exception. Turbines with a capacity of 500 MW are available, connected to an electric current generator, and the possibility of producing even more powerful units, at least up to 1000 MW, has been proven.

In the development of steam turbine construction, several stages can be noted that affected the design of turbines built in different periods of time.

In the period before the imperialist war of 1914, the level of knowledge in the field of the operation of metals at high temperatures was insufficient for the use of steam at high pressures and temperatures. Therefore, until 1914, steam turbines were built primarily to operate with moderate-pressure steam (12–16 bar), with temperatures up to 350 °C.

In terms of increasing the power of a single unit, great success was achieved already in the initial period of development of steam turbines.

In 1915, the power of individual turbines already reached 20 MW. In the post-war period, starting from 1918–1919, the trend towards increasing power continued. However, in the future, turbine designers pursued the task of increasing not only the power of the unit, but also the speed of high-power turbines when running them with a single electric current generator.

The most powerful high-speed turbine in the world at one time (1937) was the turbine of the Leningrad Metal Plant, built at 100 MW at 3000 rpm.

In the period before the imperialist war of 1914, turbine factories in most cases produced turbines with a limited number of stages located in one turbine housing. This made it possible to make the turbine very compact and relatively cheap. After the 1914 war, the tension in fuel supply that most countries experienced required a comprehensive increase in the efficiency of turbine units.

It was found that maximum turbine efficiency can be achieved by using small thermal differences in each turbine stage and, accordingly, building turbines with a large number of stages. In connection with this trend, turbine designs arose that, even with moderate fresh steam parameters, had an extremely large number of stages, reaching 50–60.

The large number of stages led to the need to create turbines with several casings, even when the turbine was connected to a single electric generator.

Thus, two- and three-casing turbines began to spread, which, while highly economical, were very expensive and bulky.

In the subsequent development of turbine construction, there was also a certain retreat in this matter towards simplifying the design of the turbine and reducing the number of its stages. Turbines with a power of up to 50 MW at 3000 rpm were built only with two casings for quite a long time. The newest condensing turbines of this power, produced by leading factories, are built with single casings.

Simultaneously with the design improvements of moderate pressure turbines (20 - 30 bar), in the period from 1920 to 1940, more economical high pressure units began to spread, reaching 120 - 170 bar.

The use of steam with high parameters, which significantly increases the efficiency of a turbine installation, required new solutions in the field of designing steam turbines. Significant progress has been made in the use of alloy steels, which have a fairly high yield strength and low creep rates at temperatures of 500 - 550 ° C.

Along with the development of condensing turbines, already at the beginning of this century, installations for the combined generation of electrical energy and heat began to be used, which required the construction of turbines with back pressure and intermediate steam extraction. The first turbine with constant pressure control of the extracted steam was built in 1907.

The conditions of a capitalist economy, however, prevent the use of all the advantages of combined heat and electricity generation. In fact, the thermal consumption capacity abroad is in most cases limited to the consumption of the plant where the turbine is installed. Therefore, turbines that allow the use of exhaust steam heat are most often built abroad for small powers (up to 10 - 12 MW) and are designed to provide heat and electrical energy only to individual industrial enterprise. It is characteristic that the largest (25 MW, and then 50 and 100 MW) turbines with steam extraction were built in the Soviet Union, since planned development National economy creates favorable conditions for the combined production of heat and electrical energy.

In the post-war period, all technically developed European countries, as well as the United States, have seen an ever-accelerating development of energy, which leads to an ever-increasing increase in the power of energy units. At the same time, the tendency to use increasingly higher initial steam parameters continues.

Single-shaft condensing turbines reach a power of 500 - 800 MW, and with a two-shaft design, installations with a capacity of 1000 MW have already been built.

As the power increased, it was also advisable to increase the initial steam parameters, which were successively selected at the level of 90, 130, 170, 250 and, finally, 350 bar, while the initial temperatures also increased, which amounted to 500, 535, 565, 590, and in some cases up to 650° C. It should be borne in mind that at temperatures exceeding 565° C, it is necessary to use very expensive and less studied austenitic steels. This has led to the fact that recently there has been a tendency towards some retreat into the temperature range that eliminates the need to use austenitic steels, i.e. temperatures at 540° C.

The successes achieved in 1915–1920 were of great importance for the development of low-power turbines and, in particular, for the development of ship steam turbines. in the field of gearbox construction. Until this time, ship turbines were operated at a number of revolutions equal to the number of revolutions of the propellers, i.e. 300 – 500 rpm, which reduced the efficiency of the installation and led to large dimensions and weights of the turbines.

Since the time when complete reliability and high efficiency were achieved in the operation of gear reducers, ship turbines have been equipped with gear drives and are operated at an increased speed, which corresponds to the most favorable conditions turbine operation.

For stationary low-power turbines, it also turned out to be advisable to use a gear transmission between the turbine and the generator. The highest speed possible with direct connection of the turbine shafts and the 50-period alternating current generator is 3000 rpm. At powers below 2.5 MW, this speed is unfavorable for a condensing turbine. With the development of gearbox technology, it became possible to manufacture turbines at higher speeds (5000–10000 rpm), which made it possible to increase the efficiency of low-power turbines, and most importantly, reduce their size and simplify their design.

Typical design of a modern steam turbine

When designing a steam turbine, a number of requirements for it are taken into account:

– reliability and trouble-free operation;

– high thermal efficiency;

– high uniformity of rotation and speed, allowing the use of high-speed electric generators with the possibility of their direct connection to the engine shaft;

– the ability to obtain any required unit power in the engine;

– the ability to automate the operation of the entire installation;

– ease of maintenance of the installation;

– compactness of the engine and its relative cheapness;

– possibility of working in a closed cycle.

Let's consider the design of a typical modern active turbine using the example of a high-pressure turbine at the Leningrad Metal Plant. The power of this turbine is 50 thousand kW at 3000 rpm. The turbine operates steam with an initial pressure of 88 bar at a temperature of 535° C.

The first 19 disks of moderate diameter are made integral with the turbine shaft. The next three disks are pressed onto the shaft. Working blades are mounted on the rims of each disk. The disks are separated by fixed intermediate diaphragms. Each diaphragm contains a stationary nozzle grid, in which the steam flow accelerates and acquires the necessary direction to enter the channels of the working grid formed by the working blades. The gradual increase from stage to stage in the height of the nozzle grids and working blades is explained by the fact that as the steam expands, its volume increases. This requires a gradual increase in the flow sections of the flow part. The nozzle grids of the first control stage are mounted in steam supply pipes, which are welded into the turbine housing. Steam is supplied to the nozzles of the first control stage through four control valves, two of which are located on the upper half of the housing, and two on the sides of the lower part of the housing. The part of the housing covering the high pressure stages is made in the form of a steel casting. The low pressure stages are located in the welded part of the housing. The turbine outlet pipe is also welded from sheet steel and is connected to the condenser by welding. By cooling the steam exhausted in the turbine, the pressure in the condenser is maintained below atmospheric pressure. Typically this pressure is 0.03 - 0.06 bar. The turbine housing has several pipes for extracting steam from the intermediate stages of the turbine. These selections are used to heat the feed water supplied to the steam boiler.

When the load changes, it becomes necessary to change the flow rate of steam flowing through the turbine. This is achieved by appropriately opening the control valves. Due to the fact that the valves close and open sequentially, part of the steam passing through the fully open valves is not crushed and enters the first stage nozzles with full initial pressure. Only that portion of the steam that passes through the partially open valve is throttled in the valve and approaches its nozzle group with reduced pressure. The method of controlling the steam inlet into the turbine, in which steam access to the nozzle groups is opened sequentially, is called nozzle steam distribution. The first stage, which receives steam from a different number of nozzle groups depending on the turbine load, is called the control stage. Along with this method of steam distribution, there is also a throttle method of steam supply, characterized in that the entire amount of steam supplied to the turbine passes through a common control valve. At partial turbine loads, the steam is subject to crushing due to partial closure of the throttle control valve.

Continuation

--PAGE_BREAK--

The turbine shaft rests on two bearings that support the weight of the rotor. The front bearing in the turbine simultaneously fixes the axial position of the rotor in relation to the stator and absorbs the axial forces acting on the rotor. Thus, the front bearing is a combined journal-thrust bearing. Its thrust part is built on the principle of a Mitchell segment bearing.

Where the shaft passes through the turbine housing there are seals called shaft end seals. The front shaft seal serves to reduce steam leakage from the turbine housing into the machine room. The rear seal prevents atmospheric air from being sucked into the exhaust pipe and turbine condenser. Suction of air into the condenser would lead to an increase in pressure in it and a decrease in the efficiency of the turbine. To prevent air from leaking into the condenser, low pressure steam is supplied to the rear seal. In places where the shaft passes through the central holes of the intermediate diaphragms, intermediate seals are installed to prevent steam from leaking from one stage to another, bypassing the stage nozzle grids.

The right end of the turbine shaft is connected by a coupling to the generator rotor, one of the bearings of which is located on the housing of the turbine exhaust pipe.

The front end of the turbine shaft is connected by a flexible coupling to the shaft of a double-sided centrifugal oil pump, which is supported by a suction pipe on a boss in the front bearing housing. Oil is supplied to the pump suction cavity under slight excess pressure using an injector.

The oil pump supplies oil to the controls of the regulation system (at a pressure of 20 bar), and also, using an injector, supplies oil to the bearings of the generator and turbine (at a pressure of 0.5 bar). At the end of the pump shaft there is a high-speed elastic speed controller, which controls the spools of the control system.

In the transverse bores of the front end of the turbine shaft there are two strikers of a safety switch, which causes a complete cessation of steam supply to the turbine if its rotation speed increases by 10 - 12%.

In modern high-power turbines, a special shaft-turning device is provided, with which you can slowly rotate the shaft of an idle turbine. The turning device consists of an electric motor connected to a worm gear.

The worm, using a worm wheel, rotates the intermediate shaft, on which, on a screw key, the drive gear is located. The latter can move in the axial direction and engage with a large gear mounted on the coupling half connecting the turbine shaft and the generator shaft. When the turbine is started, when its shaft is accelerated by steam, the drive gear rotates along the screw key and automatically disengages from the gear sitting on the turbine coupling half.

The turbine housing, as well as the bearing housings, have a horizontal connector at the level of the turbine shaft axis. In order to disassemble the turbine, it is necessary to loosen the connection between the horizontal joint flanges of the turbine housing and the bearing housings. The housing covers can then be lifted.

Modern turbines for driving electric current generators are designed to operate at a constant speed. Maintaining a constant speed is ensured by automatic regulation.

The controls are controlled by oil. Therefore, the control system is usually combined with a lubrication system.

A significant amount of heat is generated in turbine bearings, which must be removed so that the bearing temperature does not exceed the permissible level (approximately 60 ° C). Heat removal from the bearing is ensured by a circulating lubrication system, in which the oil not only reduces friction by creating a film between the shaft and the bearing shells, but also serves to cool the bearing. The heated oil leaving the bearing is used again for lubrication after cooling.

Steam turbine rotor parts (blades, disks), even at normal turbine speeds, are subject to high stresses caused by centrifugal forces. Increasing the turbine speed above the operating speed leads to such an increase in centrifugal forces that can cause a turbine failure. In order to protect the turbine from an unacceptable increase in speed in the event of a malfunction of the main control system, modern turbines are equipped with safety switches. The safety switch is usually located on the turbine shaft. If the turbine speed exceeds the normal speed by 10–12%, the safety switch causes the turbine start valve to quickly close and stop.

Features of large steam turbines

An increase in steam parameters and unit power of units, as well as the introduction of intermediate steam superheats, led to the use of turbines with a large number of cylinders. An increase in steam flow, on the one hand, increases the efficiency of the first stages of the turbine due to an increase in the heights of the blades in the high-pressure cylinder (HPC), and on the other hand, complicates the design of the last stages. The desire to increase the thermal efficiency of the cycle leads to a decrease in the absolute pressure in the condenser to 0.03 - 0.035 bar, which significantly increases the volumetric steam flow of the last stage. To obtain minimal losses with the output kinetic energy, a possibly large area swept by the blades is required. Its required value is achieved, firstly, by increasing the length of the blade and the diameter of the last stage, and secondly, by increasing the number of parallel steam flows in the low pressure part (LPP). For this purpose, it is also possible to use two-tier blades.

The maximum blade length is largely determined by strength considerations. At the same time, the problem of creating long blades is not only strength, but also aerodynamic. As the relative length of the blades increases, the risk of flow separation in the root region increases. This is a serious obstacle to further increasing the relative length of the blades. Modern methods design allow to avoid flow separations at design conditions. At partial loads in such stages, flow separations occur, covering a wide area in the root part of the wheel. These phenomena reduce the efficiency of the last stages and also have an adverse effect on the vibration strength of the wheel.

The number of steam outlets for very powerful units already reaches eight. The issue of choosing the number of unit shafts is related to obtaining the maximum output area. A single-shaft unit is simpler and usually cheaper than a two-shaft unit. At the same time, the twin-shaft unit allows the use different speed rotation of both shafts. Reducing the rotation speed of the low-pressure pump makes it possible to increase the input area of the last stage at the same level of permissible voltages and reduce losses at the output speed.

Twin-shaft units are widely used abroad. This applies not only to very powerful plants of the conventional type, but also to nuclear units operating at relatively low steam parameters and having huge volumetric flow rates in the last stages of the turbines. In addition, in a number of countries (USA, Latin American countries, etc.), a critical current frequency of 60 Hz is used, which significantly complicates the task of creating long blades at high rotation speeds (3600 rpm).

There is no consensus on which option (single-shaft or double-shaft) to give preference to. At the end of the 50s, leading specialists from foreign companies Brown-Boveri, General Electric and Siemens considered the maximum economically viable power of a single-shaft unit to be 400–500 MW. The last decade has noticeably changed the trend of most factories and firms in this matter. Domestic and foreign factories and firms design and manufacture single-shaft turbines, the power of which significantly exceeds the values considered “maximum” just a few years ago. (Currently, turbines with a capacity of 800 and 1200 MW are being manufactured and designed by LMZ, 765 MW by General Electric, 800 - 1000 MW by Siemens, 600 MW by companies in England, France, Italy, etc.). Based on technical and economic calculations, the West German company Siemens currently considers the production of twin-shaft units up to 1000 MW unpromising. At the same time, American and Western European companies produce a large number of twin-shaft units. The most powerful units (800 - 1300 MW) abroad are currently manufactured with two shafts. In the USSR, single-shaft turbines with a power of up to 800 MW were produced. Currently, LMZ and KhTGZ produce more powerful single-shaft machines.

With an increase in the initial parameters of steam and unit power of units, the question of choosing the type of steam distribution for steam turbines has again become relevant. This problem cannot be solved in isolation from the question of the expected operating modes of the turbine. Throttle steam distribution allows for the greatest efficiency in design mode. As calculations performed at LPI together with LMZ showed, the use of throttle steam distribution for the K-200–130 turbine instead of a nozzle with the replacement of the control stage by three pressure stages reduces the specific heat consumption in the turbine room of the power plant at nominal mode by approximately 0.3%, and for the turbine K-300–240 – by 0.4%. This increase in efficiency is equivalent to an increase in the efficiency of the control stage by approximately 2%.

The nozzle steam distribution, while inferior to the throttle one at nominal mode, is superior to it in efficiency at partial loads (in the examples considered, at loads less than 90% of the nominal). One of the significant disadvantages of nozzle steam distribution at high steam parameters is that due to different throttling of steam in the control valves, when they are opened differently, the temperatures of the steam flows passing through these valves can vary significantly. So, for example, with initial parameters of 400 bar, 650 ° C, the steam temperature behind a valve open 10% is 180 ° C lower than the steam temperature behind fully open valves.

Such flow inhomogeneity and the associated uneven heating of the turbine stator can cause significant thermal stresses and warping of the housing. To eliminate the unevenness of steam parameters in front of different groups of nozzles, simultaneous steam inlet into several groups of nozzles is used; in this case, the nozzle steam distribution approaches the throttle distribution, and the difference in the efficiency of partial modes between them decreases.

At the same time, the power of the control stages of the largest steam turbines reached extraordinary levels. For example, in the LMZ K-800–240 turbine its power is about 50,000 kW. Designing rotor blades of this stage for unsteady flow conditions becomes extremely difficult. For these reasons, for units with a capacity of 1000 MW and above, throttled steam distribution is preferred.

A significant advantage of throttle steam distribution with full steam supply is the improvement of the vibration characteristics of the first stage blades. Throttling steam distribution with full steam supply is beginning to be increasingly used for powerful steam turbines. Turbines with a capacity of 1000 and 1150 MW in the USA are made with such steam distribution. A turbine with a capacity of 1300 MW, designed by the Swiss company Brown-Boveri for the USA, has throttled steam distribution. New designs of turbines with a capacity of 1200–1600 MW LMZ also provide for throttling steam distribution.

Continuation

--PAGE_BREAK--

Possibilities for increasing steam turbine power

An increase in turbine power to 1600 MW and even up to 2000 MW was envisaged in a unified series, in which the head turbine was K-1200–240. This turbine, under certain conditions, can develop a power of up to 1400 MW. At elevated cooling water temperatures and pk > 4.5 kPa, based on the existing LPC, the turbine power can be increased to 1600 MW. The problem of a steam generator in the form of a monoblock or, possibly, a double block (based on the existing boiler for the K-800–240 block) is also being solved. It should also be borne in mind that the temperature of the cooling water for most state district power plants will gradually increase and that over time turbines with pk = 6.5 kPa will be used, and this will significantly increase their power.

It is advisable to select a fundamentally new power range based on the principle of doubling power, i.e. set the task of creating blocks of 2500 - 3000 MW. Solving this problem will require extensive scientific research and design work, as well as pre-production in the field of turbines, boilers and generators. Completing this work will take a long time. For such a major step, it is necessary to reconsider both the steam parameters and the fundamental structure power plant. Let us consider only the possibilities for further growth of turbine power without fundamental changes in the thermal scheme and steam parameters.

Currently, there are preliminary developments of turbines with a capacity of 2000–2400 MW, which make it possible to judge their prospects.

When solving this problem, the choice of turbogenerator speed is a central issue. With a power of over 2000 MW, low-speed turbines can compete with high-speed turbines in terms of general economic indicators and reliability. The efficiency of the HPC of a low-speed turbine is approximately the same as that of a high-speed turbine, since the latter already requires a double-flow HPC and, therefore, there is no noticeable gain from increasing the length of the blades. These considerations apply even more to DACs. In a low-speed turbine, the LPC can, in principle, due to lower output losses, have a higher efficiency than in a high-speed turbine, or the number of cylinders in it can be significantly reduced. The solution to the problem of a high-speed turbine by increasing the number of LPCs leads to a shaft line that is too long, in which vibrations are easily excited. If we limit the number of cylinders, then the only way increasing power - increasing the area S swept by the blades of the last stage. This area is proportional to d2l2 or u2l2. For reasons of flow aerodynamics, the fanning coefficient dl is limited (currently no less than 2.5). Taking this coefficient constant, we find that for a given rotation speed S~u2. For these conditions, at a given pc, the LPC steam consumption, and therefore the maximum power of the turbine, is proportional to the square of the peripheral speed of the last pc. Already now in the K-1200–240 LMZ turbine u2 = 471 m/s (u2" = 660 m/s), and at the periphery the peripheral speed significantly exceeds the sound speed. However, the possibility of its further increase cannot be ruled out.

If we maintain the loss of output kinetic energy and at the same time increase the peripheral speed, then small angles β2* are obtained, which can cause difficulties in designing the meridional section of the flow part of the last stages and a strong blade at the periphery of the rotor. In such cases, the question arises of increasing the output speed, despite the increase in output losses. This, however, is only possible to a certain limit, since due to large losses it is impossible to allow movement at supersonic speeds in outlet pipes that have an unfavorable aerodynamic shape.

When designing high-speed turbines with a power of 2500–3000 MW, there are also difficulties in designing the high pressure cylinder and especially the central cylinder due to the large lengths of the blades and the size of the rotors.

Twin-shaft high-speed turbines open the way to a significant increase in “ultimate power” while maintaining high installation efficiency due to an increase in the number of unified low-pressure pumps and low-pressure motors. The problem of two-tier steps also deserves special attention.

Due to the difficulties in designing a high-speed turbine with a power of 2000 MW or more, a low-speed turbine is being put forward as an alternative. The main disadvantages of the latter: large mass and dimensions of the main parts, which worsens the thermal state of the cylinders, and also creates difficulties in transportation, installation and repair, and increases the cost construction work on ES. However, there is a turbine power limit beyond which, given the available technical means, a low-speed turbine has an advantage over a high-speed one. For comparative assessment For turbines of these types, we will consider some of their design options.

Design options for a 2000 MW turbine at n = 3000 rpm. At TsKTI, research was carried out on the high-speed turbine K-2000–240/3000 for steam parameters of 23.5 MPa and 838/838 K. This project was based on currently used steam parameters. The cooling water temperature was assumed to be 293 and 298 K. The thermal design of the unit was considered the same as in modern turbines of the K-1200–240 type.

The mechanical properties of materials at the time of the project were expected to be 15–20% higher than at present. It was also assumed that forgings from chromium stainless steels weighing 60–100 tons for high and medium pressure rotors would be developed and that rotors without central holes would be manufactured. It was assumed that it would be possible to use forgings made of stainless maraging steels with a yield strength of 1200–1400 MPa and a weight of up to 15 tons. For titanium rotor blades, a yield strength of up to 900 MPa was chosen. Basically, the project was focused on the level already achieved mechanical properties applied turbine materials and safety margins confirmed by experience.

The main features of the project: a small number of stages in single-flow CVP and CSD due to high peripheral speeds (rotor diameters along the root sections d/ = 1400 mm); placement of CVP and CSD in one cylinder; use of a blade with a length of l2=1200 mm and a diameter of d2=3000 mm (ΣS = 90.4 m2) for the last stage of the low-pressure propeller; back pressure pk = 5.2 kPa; the separation pressure between the cylinders is 0.7 MPa. Under these conditions, the turbine turned out to be five-cylinder with eight outputs from the LPC with a total number of stages of 49 and with a central location of the HPC.

Total consumption steam G = 6500 t/h. Due to the high back pressure, a large specific steam consumption was obtained by each LPC outlet - 45 t/(m2h), while in the K-1200–240 turbine it was about 32 t/(m2h) at pk ~ 3.6 kPa. Output kinetic energy hС2 = 43 kJ/kg (~10 kcal/kg) and MC2g = 0.85. This output loss is extremely high. The internal efficiency of high pressure and respiratory pressure can be taken as 0.89, and low pressure - 0.83. The power of the CWD is about 700 MW, the CSD is about 600 MW and the CND is 8x105 MW (total internal power is 2140 MW). The CVP and CSD are unloaded by dummies from axial pressure.

The combined HPC-DCS is located in the center of the unit, and on both sides of it there are 2 LPCs. Compared to the conventional arrangement of the cylinders, this reduces the relative thermal expansion and reduces the diameter of the journal of the thrust bearing placed on the CVD side, which makes it possible to achieve an acceptable peripheral speed in this bearing. In addition, the size of the bypass pipes is reduced due to the branching of the flow immediately after the CSD. The low-frequency vibration characteristics of the high-pressure motor are also improved, since it does not have a free journal on the front bearing side.

Compared to the K-1200–240 turbine, the rotor journals are subjected to greater forces (calculated for four times the torque in the case of short circuit). They use rotor inserts with flange connections, made of particularly durable material (maraging steel). The diameters of the necks do not exceed 600 mm.

The stress of the housings and stator elements does not exceed the permissible values in already operating turbines. The blades, tail joints (herringbone type), and the rotor body are extremely stressed, especially in the high temperature region in the CSD, i.e. in the first stage area; the rotor can be made of R2M steel with a margin of 1.25 yield strength. The calculation was carried out under the assumption of operation for 100,000 hours. The production of forgings from chromium stainless steels will increase the durability of the rotors.

The length of the turbine is 49 m, it is only slightly longer than the length of the K-1200–240 turbine.

New options for connecting the LPC with the capacitor and the foundation have been developed: the outer casing is a thin-walled shell, and it does not serve as a base for centering the inner casing, which is connected through a frame directly to the foundation.

The specific metal consumption of a turbine without a condenser, according to preliminary calculations, is about 1.3 kg/kW versus 1.6 kg/kW for K-1200–240 (at pk = 4 kPa).

Design options for turbines with a capacity of more than 2000 MW at n=1500 rpm. Turbines with a capacity of 500 and 1000 MW, operating at 1500 rpm, are produced for nuclear power plants. Enormous costs were incurred associated with the manufacture of large products for this purpose, which necessitated not only the construction of new turbine shops, but also the restructuring of the metallurgical industry serving the turbine plants. Thanks to this contribution to the industry, it is now possible to solve the problem of further development of heavy-duty turbines on a broad basis, using both high-speed and low-speed turbines, depending on their economics and degree of reliability.

At CKTI they were carried out under the guidance of L.D. Frenkel design developments turbine with a power of 2000 MW at 1500 rpm, which was considered together with a high-speed turbine as an alternative solution. The 2000 MW capacity is close to the feasibility limit of a high-speed turbine, and this makes comparison of projects interesting, although this condition does not favor the low-speed turbine option.

Initial steam parameters 23.5 MPa, 833/838 K: back pressure 5.9 kPa. The final temperature of the feed water tp.v = 543 K. The flow part is located in a single-flow HPC (12 stages) with a power of about 710 MW, a double-flow CSD (2x8 stages) and three LPC (2x6 stages) with a power of 2x127 MW. The total number of stages is 64. The basis for designing the flow part of the LPC was a stage with a blade l2 = 1400 mm, d2 = 4100 mm, d1 = 2.93 and S = 18 m2. The specific steam consumption of the latest steam generator is about 33 t/(m2h). The pressure behind the central venous pressure is 3.6 MPa, behind the central venous pressure 0.37 MPa.

The efficiency of CVP and CSD is calculated to be about 0.89, and for CND 0.85. Their high values are achieved mainly due to lower output losses behind each last stage in the cylinders, especially in the LPC, where in the design mode hС2 is 20 kJ/kg, which is approximately two times lower than these losses in a high-speed turbine. Under these conditions, the specific heat consumption is only slightly less than for a steam turbine unit with a K-1200–240 turbine.

A difficult task is the design of high and medium pressure rotors, in which local temperatures exceed 803 K and stresses in the boring reach 170 MPa. In the hottest places, the rotor is cooled by steam taken before the first superheater. When these areas are cooled by 25–30 K, heat-resistant pearlitic steels can be used. The average diameters of the RVD are chosen to be 1800–1970 mm with the length of the first and last rotor blades being approximately 100 and 300 mm, and the same dimensions of the RSD are 2315–2770 mm and the RL are 150 and 410 mm. The HPC and CSD rotors are welded, drum type. The RVD weighs about 65 tons, and the RSD weighs about 110 tons.

Continuation

--PAGE_BREAK--

In the LPC, the last stage is relatively little stressed. Its working blade dimensions are far from the maximum, and the stress in the root section is due to bending average size PAS σi = 23 MPa (taking into account a pressure drop of 29 MPa). For a material with a yield strength of σ0.2~640MPa, the safety factor in the rotor is kt~2.8. All these voltages are significantly less than in high-speed turbines of the same power.

The weight of the RND is 145 tons; nк = 2820 rpm. The total mass of the turbine is about 3100 tons. The length of the turbine is about 56.5 m.

Comparison of low-speed and high-speed turbines. Studying the designs of high-speed and low-speed turbines leads to the conclusion that the K-2000–240 turbine can be made of both types. In terms of efficiency, both types of turbines should not differ significantly.

Both turbines are designed with five cylinders. At the same time, the weight of the high-speed turbine (without a condenser) was less than the low-speed one by more than 20%. But a low-speed turbine can be made with a last blade length of 1600 mm or even more at dl~3, and then the swept area of the last rotor blade will be 27 m2, which is 1.5 times larger than that adopted in the project and 2.4 times greater than the same area in high-speed turbine with the last blade 1200 mm long. At the same time, the number of LPCs in a low-speed turbine will be reduced, and it will become more competitive.

In the project, the low-speed turbine is approximately 6.5 m longer and slightly wider than the high-speed turbine (the width is determined by the size of the LPC outlet pipe).

Among positive factors low-speed turbine, we note: low peripheral speeds and voltages in the RSD, rigid and relatively heavy rotors. The latter makes it easier to eliminate low-frequency vibration. But still, these advantages cannot be considered decisive when considering a 2000 MW turbine. The advantages of a low-speed turbine could be revealed with significantly higher power and with an optimal number and size of LPC.

Thus, the steam turbine is the main engine at thermal power plants and has a number of advantages compared to other types of engines:

– rotational operating principle;

– high speed and the possibility of non-sequential connection with the generator shaft;

– high thermal efficiency provided that high initial and low final steam parameters are used;

– unlimited unit power;

– the ability to use any industrial look fuel.

The disadvantages of steam turbines include:

– large dimensions and weight;

– high demands on steam purity;

- need in large quantities cooling water;

– impossibility of creating a highly economical low-power steam turbine.

Thermal cycles of operation of thermal power plants.

In the first half of the 19th century. physicist and engineer Carnot first considered an ideal reversible cycle, consisting of two isotherms and two adiabats (Fig. 6), and determined the thermal efficiency of the cycle />.

Rice. 6 Carnot cycle in T-S diagram

The working fluid expands isothermally with temperature />=const from point 1 to point 2 when heat is supplied />, and from point 2 to point 3 – adiabatically, i.e. without heat supply or removal. The temperature at the end of expansion T2 is less than the temperature T1. From the state at point 3, the body transitions to the initial state at point 1, first along the isotherm T2 = const with heat removal />, and then along the adiabatic curve (line 4–1).

In the T-S diagram, the area under the curve of a thermodynamic process is numerically equal to the amount of heat involved in it. The amount of heat supplied />is numerically equal to the area of the rectangle />, and the amount of heat removed /> is equal to the area of the rectangle />. Therefore, the area of the rectangle 1234 is numerically equal to the amount of heat converted into mechanical energy:

Let us consider an ideal Carnot cycle in the wet steam region.

At the end of the heat removal process in the Carnot cycle, ddegree of dryness 0<1, поэтому в последующем процессе сжатия daдолжен сжиматься влажный пар от начального состояния />up to x=0 (i.e. a). Since /> is determined by the change in specific volume, the work spent on compression will be very large (the change in specific volume is 3 orders of magnitude). Moreover, in order to increase the efficiency of the Carnot cycle, that is, increase // and decrease //, it is necessary to increase the initial pressure and reduce the final one, while the end point of the heat removal process, i.e., shifts to the right (to the area of drier steam), so the energy consumption for compression will increase. In addition, since at the beginning of the compression process there is wet steam, and at the end there is saturated liquid, the compression process itself cannot be carried out either with the help of a compressor or with the help of a hydraulic pump. Due to these features, the Carnot cycle was modified and received the name Rankine cycle. The only changes were that the heat removal process is carried out until the working fluid is completely condensed.

Continuation

--PAGE_BREAK--

Therefore, in the further compression process, it is not the wet vapor that is compressed, but the liquid. Since the change in volume with a change in pressure for a liquid is small, therefore the work of compression in the Rankine cycle turns out to be significantly less than in the Carnot cycle, that is, de can be considered an isochore. And since compression occurs under ideal conditions, that is, adiabatically, the de line is called an isochore or isentrope.

Let's consider the operating cycle of thermal power plants in the T-S diagram.

When heat is supplied and removed, the phase state of the working fluid changes (liquid - vapor - liquid). Heating of water in steam generator 1 to saturation temperature //at pressure р(line 1–2), steam formation (line 2–3) in steam generator 1 and superheating of steam (line 3–4) in superheater 2 of the steam generator occur at р=const. Using the T-S diagram, you can determine the phase state of 1 kg of working fluid at any point in the cycle.

In the region of saturated steam, the isobaric process (line 2–3) coincides with the isothermal one, i.e. vaporization occurs at constant pressure and temperature Tp. Water enters steam generator 1 with heat content />, which is represented by area 1a0d. The amount of heat spent on heating water to the saturation (boiling) temperature is numerically equal to an area of 12 ba; for steam generation - an area of 23 wb; for steam overheating - area 34 gv. The total amount of heat transferred to the working fluid is numerically equal to the area of 1234 hectares. This is the amount of heat during the isobaric process of its supply

In an ideal turbine, steam expansion occurs along an isentropic path (line 4–5). After the turbine, the steam enters the condenser, where it transfers heat to cooling water, which enters a cold source (river, lake, etc.). The process of condensation of steam exhausted in the turbine is shown by line 5–1. The amount of heat transferred to the cold source is numerically equal to an area of 51 ag:

where />kcal/kg in steam turbine units operating in deep vacuum.

Steam condensation occurs at a constant temperature />and constant pressure />kgf/cm, i.e. isobaric and isothermal processes coincide.

State and prospects for the development of domestic steam turbines.

For a long time, the domestic power steam turbine industry was at high level. Turbines and other turbine unit equipment (TTU) are designed and manufactured at Russian factories and two Ukrainian ones - Kharkov Turbine Plant (now Turboatom) and Sumy Pump Plant. All power plant equipment has been completed on our own in contrast to, say, the USA and Japan, where imported equipment (in particular, steam turbines) is also used.

Our factories have created steam turbines, turbines and their elements, many of which have not yet been surpassed abroad. In this regard, we can note the world's largest single-shaft turbine SKD LMZ K-1200–23.5 for driving a two-pole electric generator, which has been successfully operating at the Kostroma State District Power Plant for more than 20 years. In general, in the Russian Federation the number of supercritical pressure turbines (SCP) is greater than in any other country: 100 condensing turbines. At the same time, almost the entire energy industry in Europe (except for the CIS countries), developing countries and, to a large extent, the United States, until recently, was focused on subcritical pressure p = 16.3 - 18 MPa. Abroad, at steam power thermal power plants, such a deep design vacuum is rarely encountered as at our thermal power plants - at tcool.v = 12 C, although this significantly complicates the creation of powerful turbines.

Only in countries former USSR For a long time, high-speed five-cylinder saturated steam turbines with a capacity of 500 and 750 MW produced by Turboatom and a capacity of 1000 MW by LMZ were in operation. The layout of these turbines is 2 LPCs on each side of a double-flow HPC; complex multi-support shafting has good vibration characteristics. Some domestic powerful NPP turbines, low-speed at 25 1/s: Ne>500 MW Turbatom turbines for double-circuit NPPs with VVER reactors.

Almost half of the power plants in the Russian Federation using fossil fuels are thermal power plants with economically and environmentally favorable combined heat and electricity generation. In total, outside the CIS countries there are not as many heating turbines as those developed by TMZ and LMZ, there is not such a variety of designs, layouts, and capacities. The world's first heating turbines SKD with a capacity of up to 300 MW (T-250/300–23.5 TMZ) were introduced in the early 70s. Currently, 22 such power units are in operation at Russian thermal power plants.

In our country, for the first time, two-stage heating extraction systems and unregulated pressure heat extraction systems were used. Now such systems are widely used both here and abroad, where in last years, including in Northwestern Europe and China, thermal power plants have become widespread, and in Denmark, using coal-fired power units with a capacity of up to 400 MW and higher. However, in this area, both in terms of parameters and efficiency, we began to lag behind, increasingly supplying small units to our own thermal power plants, which are ineffective and relatively expensive.

It is known that the most complex element of the turbine is the last stage. An increase in its length (at the same rotation speed n) and annular area Ω largely characterizes the technical level of a turbine plant or company. One of the progressive ways to solve this problem (after about 5 years, each company switches to the latest large-sized blades) is to manufacture blades from a titanium alloy. For the first time, such blades, first 960 mm long and then 1200 mm long with Ω = 11.3 m2, were installed on LMZ turbines. Many leading companies have also tried to install titanium blades in the last stages, but often unsuccessfully. Only since 1992, and in the USA by the American company General Electric (GE) and later, Japanese companies put into operation turbines with titanium blades 1016 mm long.

But even with a lightweight titanium alloy, it is not easy to withstand the centrifugal force of long blades. At first, a welded rotor was used for this, and then for the low-pressure drive of the LMZ K-1000–5.9 turbines, a unique large-sized rotor without central drilling was manufactured at the Izhora plant. Rotors without a central hole, especially of this size, are not used anywhere yet. Only the designs of these rotors developed by Siemens for their powerful advanced turbines are known.

Continuation

--PAGE_BREAK--

Among other achievements of our turbine construction, it is worth noting the package design of working blades used by LMZ in the control stage (with a power of 50 MW) of the K-800–23.5–5 turbine. With partial steam supply new design LMZ allows several times higher bending stresses than was previously accepted. Blade packages are used by LMZ and Turboatom in other stages of their turbines. Bunching with ring ligation not only increases the reliability of the blades, but also makes it possible to increase the efficiency of the stages, especially under variable operating conditions.

In large-scale turbine construction, all characteristics of steam turbine units were favorably affected by competition: for condensing units LMZ and Turboatom, for heating units - TMZ and LMZ.

The advantages of domestic turbines, including those mentioned above, are explained by the corresponding level of steam turbine construction. This is facilitated by the training of highly qualified engineering and scientific personnel in the country’s leading universities, Scientific research large volumes, variety, depth, carried out in factory laboratories and design bureaus, in research institutes, in technical universities. Internationally recognized scientific and design schools were created. Turbine plants were equipped with modern technological, control and experimental equipment. For example, of the three experimental full-scale stands available in the world, two are located here - at LMZ and TMZ. In training personnel, including workers, in analyzing and mastering existing experience, in using the best scientific and technical developments Technical literature plays a significant role. There are more books in Russian on steam turbines, technical training schools, and related problems than in other languages in total. Our literature on steam turbines is translated into foreign languages. For example, only the books of the professor of the Department of Steam Turbines at Moscow Power Engineering Institute were published in 12 languages. Let us note that some countries with a developed turbine industry (USA, France, Japan) do not have their own books on steam turbines, the content of which corresponds to the modern level.

All turbines of domestic plants widely use turbine cascades, standard stages, flow parts, and other elements of the steam path created by us. They are aerodynamically tested, sometimes have an unconventional shape, tested in wind and steam dynamic tunnels, in experimental turbines (ET), on full-scale test benches, and at power plants. TsKTI and St. Petersburg State Technical University have unique ETs with a split shaft. A significant place in research and development, up to fine-tuning at power plants, is given to vibration detuning of blades and rotors, variable modes, sometimes very complex - these are low-pressure pressure modes with reduced volumetric steam flows GКvK. More than anywhere else, the volume and breadth of research on the gas dynamics of wet steam and moisture separation are most significant. The result of the development of turbine reconstructions carried out by factories, power plants, scientific institutes and commissioning organizations is that many turbines, including very powerful ones, instead of the original design resource of 100 thousand hours, operate for 200 thousand hours or more. Russian and Ukrainian factories exported turbines to dozens of countries. This profitable export of science-intensive products continues today. However, one cannot fail to note serious shortcomings in the development, manufacture and operation of domestic vocational schools. These often do not include high quality auxiliary equipment. This was facilitated by the fact that for a long time turbine plants were not responsible for the entire steam turbine plant, but only for equipment of their own manufacture: a turbine and a condensing unit. When testing PTUs at power plants, assessing the operation of plants, their design bureaus, and comparing them with warranty indicators, corrections were introduced for the real characteristics of “foreign” equipment: heaters, pumps, their drives, nuclear power plant separators-reheaters, fittings, etc.

The main foreign firms, concerns, and transnational companies producing turbines are diversified. They also create electronic and computer equipment, including those used in the military industry. This applies to the design of turbines, robots for the manufacture of blades, control systems, control equipment, measurements, etc. We have a different situation, which basically remains to this day, despite individual cases of using the results of the conversion of the military-industrial complex. Today, to a large extent, new programs, CAD, and diagnostics based on modern computers are widely used when carrying out R&D, and during the production and operation of turbines in vocational technical schools. All this, including completely automated systems control and protection, as well as primary elements for automated process control systems, is largely due to developments coming from the military-industrial complex. Thus, in the flow parts of gas turbines, some new design and aerodynamic solutions are used, which are later and to a lesser extent used in domestic steam turbines, although it was for them that they were proposed and studied at technical universities and research institutes. The following have become widespread in new foreign turbines: special profiling of the meridional contour of low-height nozzle blades developed at MPEI; fully spatial calculation, taking into account the influence of viscosity and the mutual influence of lattices; blades inclined (with a variable radius angle of inclination) in the direction of rotation, proposed by the Moscow Power Engineering Institute and called “saber-shaped”; directed root interventional leaks; original seal designs and much more. Moreover, most of the solutions listed above were first proposed or developed in Russia, and in foreign literature our priority is often referred to.

Often, changes in turbine designs, although they provide increased efficiency and reliability, entail an increase in the cost of R&D and the turbine itself and are therefore rarely used by factories in the Russian Federation.

When exporting power equipment, including industrial technical equipment, the contracts concluded always indicate its warranty characteristics. If the tests show deviations of the efficiency of the STP from the warranty, then the manufacturer pays the buyer (the power plant or the energy system) or, conversely, receives material incentives, which in our country, however, almost does not yet reach the direct creators of the turbines and STP. Unfortunately, there is no such rule for domestic supplies, and the cost of the unit practically does not depend on its actual characteristics obtained during testing and operation. Also no financial liability manufacturers when equipment reliability decreases. Of course, when it breaks down, the plant supplies (not always itself) new parts and makes repairs, but does not compensate for the unplanned underproduction of energy. In recent years, a significant share of the profits, and even the workload of foreign power engineering firms, has been ensured by contracts for constant long-term maintenance of equipment at the end of a short, only two-year warranty period. Such agreements should be binding in our country too. It would be fair if all deviations from the warranty characteristics should have a material impact on the performers, especially now that the majority of enterprises have been fully or partially privatized.

Recently, the number of equipment malfunctions has increased: increased vibration rotors; blade breakage, especially in stages where the steam expansion process occurs near the boundary curve; diaphragm deflections, etc. Thus, on one of the largest multi-cylinder low-speed turbines at a nuclear power plant, in the fourth from the end of the LPC stage, there were breakdowns or cracks were discovered in the blade shanks. They require complete rework, the cost of which is extremely high. Apparently, a contract with the plant for constant maintenance, which would include the cost of unscheduled repairs and forced replacement of parts, would have cost the power plant less.

In recent years, there has been a tendency in the global energy sector to create significantly improved equipment, including turbines and steam turbines. At almost all steam power (fossil fuel) power plants recently built by foreign companies, currently under construction and ordered for commissioning before the end of the last century and at the beginning of this century, the net efficiency of the power unit instead of the recent >> = 36–39% has increased to 43–46% (sometimes already based on test data) and it is planned (and for power plants operating on coal) to increase it to 47–49%.

This increase in the efficiency of power units is explained by an increase in the parameters of fresh steam, reheating and feedwater temperatures, deepening of the vacuum, and radical improvement of equipment: main (boiler plants and steam turbines) and auxiliary. For powerful turbines (and we are talking about units up to /= 1000 MW) - approximately half of the gain in efficiency of the entire power unit is determined by changing the parameters, the other half - by improving the design of the turbine itself. New turbine improvements, including those mentioned above, provide a greater share of the increase in efficiency, the lower the power.

Now, starting with />, as a rule, SKD turbines are created. Taking into account a set of measures to reduce end losses in grids and seals, the technical and economic feasibility of SKD is considered even at />, starting from 100 MW. Steam parameters at individual power units increase to 28–31 MPa, 580–600 />; a number of companies have begun design work with the transition to />; studies have appeared on the possibility of transition to the seemingly fantastic temperature of 720 />.

However, our power units with steam pressures in front of the turbine: 12.8 and 23.5 MPa were forced to transfer from temperatures of 560/565 to 540/540/> (not counting the experimental industrial turbine KhTZ SKR -100, described in detail in the literature, to 30 MPa, 650/>). Over the past 30 years, not a single turbine has been created or even designed (or ordered) for new, increased steam parameters. Apart from individual, partial improved cardinal changes in the flow path of turbines and in the steam turbines, there are still no design studies for some elements.

Continuation

--PAGE_BREAK--

What is also alarming is the fact that the volume of research, especially experimental research conducted at the factories themselves and at their request in research institutes and universities, is being reduced. Of course, the reduction industrial production affects the demand for electricity. However, in some regions it is still not enough. What a huge excessive consumption of fuel, what aggravation of the environmental situation in connection with this is due to the fact that relatively large boiler houses in the Russian Federation supplied 2 times more heat than thermal power plants. But, the main thing is the avalanche-growing shares of the exhausted physical resource equipment. Today this is 20 million kW, and by 2010 this figure will reach 90 million kW, i.e. almost half of the generating capacity in RAO UES of Russia, not to mention small utility and industrial turbines, where units even from pre-war production are still in operation.

The low reliability of equipment requires increasingly frequent and expensive repairs. This is a problem not only for ours, but for the entire world energy sector. Of course, at the same time, obsolescence of this equipment also occurs. It is recognized that the newest steam turbines, compared to those designed 10–15 years ago (and we have the vast majority of them), with the same parameters and the same exhaust area, can increase the efficiency of the steam turbine by 4.5–6.0% (relative). It should also be taken into account that soon, due to the end of the permissible operation period of nuclear power plants, their power units will have to be shut down, including those with a capacity of 1000 MW, many of which are located in the countries of the former USSR, including the Russian Federation. This applies primarily to the Leningrad NPP with a nominal capacity of 4 million kW, which so far provides a significant part of the electricity generation of the entire northwestern region of Russia. NPP turbines to replace power units that have exhausted their resources must have an efficiency corresponding to the modern level.

The problem of technical re-equipment of equipment that has exhausted its resource cannot be solved without a simultaneous radical increase in its efficiency. And here, for the first time in our history, domestic industry faced competition from foreign firms. To replace the equipment of power plants in the countries of the former CMEA, an economic consortium has been organized, including leading power engineering and metallurgical companies Western Europe. A number of firms are making efforts to secure these orders, the first part of which alone is estimated at $2.3 billion. Projects for the modernization of specific turbines have already been presented. For example, at the SKD power unit with a capacity of 300 MW with a Turboatom turbine at the Zmievskaya State District Power Plant, it was proposed to replace the HPC with a pot-type cylinder from Siemens, the CSD of the Alstom project - DEC, leaving the Kharkov HND unchanged. The practice of domestic energy has a sad experience of combining turbines with a capacity of 500 MW, the individual elements of which were created different factories. They were accompanied by repeated breakdowns, and it is not clear which manufacturer is responsible for this.

There is no doubt that if in the future, even not so distant future, there will be no improvement in all operational indicators of power units, their steam turbines and turbines, including efficiency, reliability, environmental friendliness, if these indicators turn out to be worse than those of the equipment offered foreign companies, the domestic power engineering industry will cease to exist. And until recently, it was one of the branches of peaceful industry where we could successfully compete with other developed countries. Ultimately, this situation will lead to the loss of energy independence. playing a decisive role in the independence of the country. In order to imagine what awaits us in the future, let’s consider the situation in Kazakhstan. There, management of the national energy sector was transferred to the transnational concern ABB for 25 years. It is naive to think that everything power equipment, including steam turbines, both new and reconstructed, will be manufactured. as before, at Russian factories, not ABB. It is clear where spare parts will be supplied from and where repairs will be carried out.

Along with many, today almost uncontested ways to increase the efficiency of the flow path and reduce losses in the entire steam path, there remain some issues of optimal development of steam turbines that require discussion. One of them is the design of cylinders and turbine parts for multi-cylinder units, these include turbines with a power of more than 200, and sometimes even 100 MW.

Low pressure cylinders are usually double flow with neutral steam supply. If the dimensions of the last stage and the volumetric passage allow us to limit ourselves to one flow, then it is logical to abandon the basement and even more favorable side arrangement of the capacitors. The axial condenser significantly increases the efficiency of the complex: the last stage + outlet pipe, significantly reduces construction costs in the turbine hall. Such a project for a 300 MW turbine is available in France. In relation to our conditions, MPEI has developed options for a single-flow turbine of even greater power with a worse vacuum and the use of a very long LMZ-MPEI blade.

High-pressure cylinders can be single-flow: K-200–12.8 LMZ; T-100–12.8 TMZ; turbines of the SKD Turboatom series; Most cars are from European companies. For SKD turbines, LMZ uses loop-type LPC with a central steam supply. Its advantages are balancing of axial forces, lower end leakage. The results of detailed calculations as well as some tests carried out by ORGRES. Especially after installing diffusers behind the last stages of both compartments, they showed greater efficiency compared to a single-flow HPC. In Mitsubishi turbines with a power of 700 MW, the HPC is made with a central steam supply and two symmetrical flows, including two control stages. Another design of a reactive type HPC requires a dummis, sometimes even two. In this case, additional leaks appear, the greater the smaller />.

The medium-pressure cylinders of LMZ turbines with a power of />=200 MW, other high-power turbines are single-flow; in SKD LMZ units from 500 to 1200 MW, as well as in many powerful foreign turbines, they are double-flow. They are more efficient, but due to the very long and flexible rotor, during operation and frequent starts and stops, leakage in the stages increases. This can be avoided by using gap control in active turbines. The design of the steam turbines SKD LMZ and Turboatom K-300–23.5, where the ChSD and one of the three flows of the ChND are connected in one cylinder, is not entirely successful. Before ChND-1, 2/3 of the steam flow is taken, and its first stages flow around with increased losses. In such a long single-stream combination of DSND, a dummis is required, which reduces efficiency and maneuverability and requires cooling. A variant of a combined CSND with a central steam supply is possible, but it is structurally more complex.

In many large American and Japanese turbines, as well as in the studies of the Moscow Power Engineering Institute, a combined high-pressure propulsion system has been adopted. In the Japanese turbine K-600–24.1, its use made it possible to abandon the DSD and reduce the axial dimensions of the turbine unit by 8 m, making it a three-cylinder unit. At high temperatures, its advantage is the natural cooling of the high-temperature section of the CSD rotor and the entrance to the CSD by leakage through the intermediate seal; the disadvantage is the large length and sometimes increased diameter of the rotor. But in the mentioned 600 MW turbine from Toshiba at n=50 1/s there are only 15 stages in the high-pressure cylinder. The Izhora plant can also produce long rotors at elevated temperatures without central drilling. Depending on the selected LPC rotor (with a 960 or 1200 mm blade), the 525 MW pilot power unit proposed by MPEI can be four-cylinder (as is now the LMZ and Turboatom K-500–23.5 turbines) or three-cylinder.

The choice of one or another design of a multi-cylinder turbine at different powers and pressures in the condenser makes it possible to produce a large series of turbines from a set of cylinders that are identical or differ only in the height of the blades. Today, with intense competition, this is very important, because it preserves the necessary R&D complex and significantly reduces the duration from the start of order fulfillment to putting it into commercial operation. This, in particular, is emphasized in foreign publications devoted to the specifics of power engineering in market conditions.

Since the time of the first turbines, the position of companies and factories in choosing the type of blading (active and reactive) has been different. This applies to CVP and CSD. Reactive blading improves the flow around the working grids and reduces output losses. But at the same time, especially for low-height blades, leakage losses increase, although today for one stage they are reduced by different seals with 10–16 ridges. At the same time, the number of stages increases and, accordingly, the cost of the unit. Active type turbines currently make it possible to significantly increase the efficiency of stages using certain measures, including inter-crown root leakage. However, active type turbines require high quality manufacturing and design of diaphragms, the thickness of which increases with increasing p