Assortment of poultry products. Product characteristics of poultry and game meat. Poultry meat quality certificate

Poultry farming- a branch of livestock farming whose task is to breed poultry. In meat poultry farming, chickens of meat breeds and lines, ducks, turkeys, geese, and less often guinea fowl and quail are used.

Poultry meat

Main types of poultry– chickens, geese, ducks, turkeys, guinea fowl and quail. Poultry meat is valued for its high taste. It consists of the same tissues as the meat of slaughtered animals, but has distinctive features. Poultry meat is more tender, muscle tissue contains less connective tissue, it is easier and more completely absorbed by the human body.

Poultry meat is divided by type, age, processing method, and thermal state.

The bird is distinguished by its high precocity, reaching slaughter weight at 2-3 months of age, and also with a high yield of edible parts (55-65%). The slaughter yield of gutted poultry carcasses reaches 57-60%, semi-gutted - 77-80%.

The fats contained in meat determine the high energy value of meat products, participate in the formation of aroma and taste of products and contain polyunsaturated fatty acids in sufficient quantities for humans. The muscle tissue of meat contains extractive substances that are involved in the formation of the taste of meat products and belong to the energetic stimulants of the secretion of the gastric glands. A person receives all the minerals he needs with meat and meat products. Meat foods are especially rich in phosphorus, iron, sodium, and potassium. In addition, meat contains a number of microelements.

The nutritional value poultry meat is characterized by the amount and ratio of proteins, fats, vitamins, minerals and the degree of their absorption by the human body; it is also determined by the energy content and taste properties of meat.

All these characteristics, along with the relatively low cost, have made poultry meat extremely popular, both in home nutrition and in the preparation of dishes at catering establishments, including therapeutic and prophylactic products.

The purpose of this course work is to study the commodity characteristics and examination of the quality of poultry meat.

In accordance with the goal, the following tasks were formulated:

1 study the chemical composition and nutritional value of poultry meat;

2 consider the factors shaping the quality of poultry meat;

3 study the classification and assortment of poultry meat;

4 study the requirements for packaging, labeling, transportation, storage and sale of poultry meat;

5 consider ways to falsify poultry meat;

6 study the requirements for the quality of poultry meat.

Poultry meat is a carcass or part of a carcass obtained after the slaughter and primary processing of poultry and representing a combination of various tissues - muscle, connective, fat, bone, etc.

In terms of chemical composition, poultry meat differs from the meat of slaughtered animals in its increased content of biologically valuable proteins and easily meltable fat. Poultry meat contains (in%): water - 50-70; proteins – 16-22; fat – 16-45; minerals and vitamins, extractives, small amounts of carbohydrates (glycogen).

The nutritional value of poultry meat is characterized by the amount and ratio of proteins, fats, vitamins, minerals and the degree of their absorption by the human body; it is also determined by the energy content and taste properties of meat. Meat with an equal content of proteins and fats is better digestible and has good taste.

Muscle tissue has the greatest nutritional value, since it contains predominantly complete proteins with the most beneficial essential amino acids for the human body.

The percentage of incomplete proteins to complete ones in poultry meat is about 7%, and in beef – 15-20%. Different muscles of the same bird have different chemical compositions.

The chemical composition of poultry meat depends on the same factors as the composition of meat from slaughtered animals: age, fatness, breed, fattening conditions, part of the carcass, type of bird. The good digestibility of poultry meat (96%) is explained by its chemical composition.

Due to its melting properties, fat is easily digestible, and when frying poultry, it is evenly distributed throughout the muscle tissue. Poultry fat belongs to the group of solid fats. Its digestibility by the human body is about 93%. The composition of poultry fat consists mainly of triglycerides of stearic, palmitic and oleic fatty acids (the latter constitutes up to 47% of all fatty acids that make up goose fat). In addition to the fatty acids listed, chicken and geese fat also includes linoleic, myristic and lauric acids. Volatile fatty acids contain no more than 0.1-0.2%. The acid number of internal fat is higher than that of subcutaneous fat. It has a high iodine number (64-90), acid number - 0.6.

Intermuscular fat has the lowest melting point. The melting point of poultry fat is influenced by feed. The coloring matter of bird fat is carotene and xanthophyll. The chemical composition and nutritional value of poultry meat are presented in Table 1.

Table 1 - Chemical composition and nutritional value of poultry meat (per 100 g of product)

| Chickens | Geese | Turkeys | Chickens | Ducks | ||||||

| 1st | 2nd | 1st | 2nd | 1st | 2nd | 1st | 2nd | 1st | 2nd | |

| Water, ml | 63,8 | 67,7 | 45 | 54,4 | 57,3 | 64,5 | 61,9 | 68,1 | 45,6 | 56,7 |

| Proteins, g | 18,7 | 19,7 | 15,2 | 17 | 19,5 | 21,6 | 18,2 | 21,2 | 15,8 | 17,2 |

| Fats, g | 16,1 | 11,2 | 39 | 27,7 | 22 | 12 | 18,4 | 8,2 | 38 | 24,2 |

| Ash, g | 0,9 | 0,9 | 0,8 | 0,9 | 0,9 | 1,1 | 0,8 | 0,9 | 0,6 | 0,9 |

| Minerals, mg | ||||||||||

| Na | 70 | 88 | 91 | 99 | 90 | 100 | 70 | 79 | 58 | 90 |

| K | 236 | 242 | 240 | 274 | 210 | 257 | 194 | 240 | 156 | 160 |

| Ca | 14 | 12 | 12 | 14 | 12 | 18 | 16 | 18 | 10 | 12 |

| Mg | 19 | 22 | 30 | 34 | 19 | 25 | 18 | 21 | 15 | 13 |

| P | 160 | 175 | 165 | 179 | 200 | 227 | 165 | 190 | 136 | 156 |

| Fe | 1,3 | 1,7 | 2,4 | 2,4 | 1,4 | 1,8 | 1,6 | 1,5 | 1,9 | 1,9 |

| Vitamins, mg | ||||||||||

| A | 0,04 | 0,03 | 0,02 | 0,02 | 0,01 | 0,01 | 0,07 | 0,07 | 0,05 | 0,05 |

| IN 1 | 0,09 | 0,11 | 0,08 | 0,09 | 0,05 | 0,07 | 0,07 | 0,07 | 0,12 | 0,18 |

| AT 2 | 0,15 | 0,16 | 0,23 | 0,26 | 0,22 | 0,19 | 0,15 | 0,14 | 0,17 | 0,19 |

| RR | 6,1 | 6,4 | 5,2 | 5,6 | 7,8 | 8 | 7,7 | 7,8 | 5,8 | 6 |

| Energy value, kcal/100 g | ||||||||||

| ---- | 183 | 127 | 412 | 317 | 276 | 197 | 241 | 161 | 405 | 287 |

Having analyzed the data in Table 1, we can say that the most water is contained in the meat of chickens and hens (61.9 -68.1 ml), the least in geese and ducks (45.0 - 56.7 ml). The maximum amount of proteins in turkey meat (19.5021.6 mg). The second place in the amount of protein among poultry meat is occupied by hens and chickens (18.2 - 21.2 g). The least protein is found in the meat of geese and ducks (15.2 - 17.2 g).

The meat of geese and ducks is rich in fats (24.2 - 39.0 g), chickens, chickens, and turkeys have less fat (8.2 - 22.0 g). The least amount of ash is found in duck meat (0.6 - 0.9 g). For other types of poultry meat, the ash content is relatively the same (0.8 -1.1 g).

Poultry meat contains most of the known minerals, but potassium predominates - most in turkeys and ducks (up to 257 mg per 100 g of meat), phosphorus - most in turkey (up to 227 mg per 100 g), calcium (up to 18 mg per 100 g of meat). d), sodium (up to 100 mg per 100 g), iron (up to 2.4 mg per 100 g), magnesium (up to 34 mg per 100 g). Among the vitamins in poultry meat there are: (in mg per 100g) - A (up to 0.07), B 1 (up to 0.18), B 2 (up to 0.26), PP (up to 8.0).

Goose meat is fattier than duck (up to 20% fat) and tougher. Turkey meat is very tender and never causes allergies, so it is recommended for children. Compared to other types of birds, it contains a small amount of cholesterol - 74 mg per 100 g. It is rich in iron, selenium, magnesium and potassium, and contains vitamins: PP, B 6, B 12, B 2.

Chicken meat, based on its chemical composition, can be classified as a dietary food. The most useful is white boiled chicken meat (especially breast), which is considered a dietary product.

There are more proteins in poultry meat (chickens, turkeys) than in the meat of slaughtered animals, and they are mostly water-soluble. Poultry proteins contain virtually no collagen and elastin, which characterizes its good digestibility and nutritional value (a lot of complete proteins). Poultry meat contains all essential amino acids (up to 3000 mg per 100 g of edible portion) and up to 11,000 mg of non-essential amino acids.

White meat contains more extractive substances, so consuming poultry broth promotes increased secretion of digestive juices. In this regard, the meat of adult poultry is more valuable. Land poultry meat is suitable for children's and dietary nutrition.

A person receives all the minerals he needs with meat and meat products.

Poultry offal is inferior to meat in terms of fat content, but is almost equivalent in protein; its energy value ranges from 662 kJ (heart) to 1037 kJ (neck).

The morphological composition of poultry meat differs from the composition of slaughtered animals in that the bones of the poultry skeleton are thin and light, but very strong.

The skeleton of a bird consists of the bones of the skull, spine, chest, pelvis, wings and legs. The spine is fused. The long bones are empty (without a brain) and filled with air, which enters through the endings of the pulmonary bronchi, which allows the bird to fly. Bone tissue makes up 14% of live weight.

The muscle tissue of poultry is quite dense, finely fibrous, and less layered with connective tissue (it is looser than that of animals). The muscle fibers of meat breeds of birds are thicker than those of egg-laying birds, and thicker in males than in females. The color of the muscles characterizes the bird species. So, in chickens and turkeys the color of the muscle is white with a pink tint, and in geese and ducks it is dark. The mass of the pectoral muscles is large and sometimes exceeds the mass of the thighs and lower legs. The thoracic part is 24.7%, the leg part is 32.85, the dorsal-scapular part is 24.2%, the neck is 7.3%, the wings are 10.5%.

Fat deposits in poultry are located under the skin (on the back, chest, abdomen, in the tail area), on the intestines and stomach. If fat is distributed evenly throughout the muscles, the meat is tastier and more tender. An adult bird is fatter than a young bird. The total amount of fat is greater in geese and ducks - up to 45%, somewhat less in chickens.

The bird's skin is thin, mobile, white or yellow.

The bird's digestive organs are the crop (the protruded back of the esophagus), in which food is moistened, and the stomach, where food is ground by strong muscles, which are helped by coarse sand pecked by birds.

The bird's legs consist of metatarsus and toes, covered with flat scales of various (usually yellow) colors.

The ratio of edible and inedible parts of a bird depends on the species, fatness, age, and method of fattening, especially due to the accumulation of fat.

Edible parts vary depending on the fatness category from 59.6 to 65.6%, including muscle tissue accounting for up to 55%, edible offal - up to 10%. Inedible parts account for up to 35-40%, including bones - 14-18%; feather, blood – 22%.

The quality of poultry meat is formed under the influence of a number of factors: both intravital, characterized by the characteristics of the genotype, housing conditions, and post-slaughter - processing technology, storage, etc. In addition to hereditary factors (species, breed, line, cross), gender and age, the quality of meat is also influenced by environmental factors, in particular feeding. The level of protein, metabolic energy, combination of feed in diets, etc. are important in feeding poultry. For example, the amino acid composition of vitamin-mineral premixes and feed affects the rate of metabolism and the formation of lipids in the body; The fatty acid composition of meat is associated with the addition of vegetable and animal fats. The quality of poultry meat is also affected by housing conditions. Thus, broilers raised in cages have fattier meat than their peers, which are kept on the floor, on deep litter. Ultraviolet irradiation of chickens increases lipids and dry matter in muscle tissue, which improves meat quality and nutritional value.

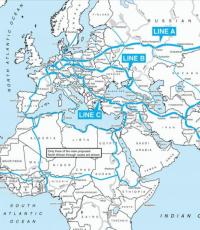

Classification V.V. Gushchin, allows you to systematize according to general principles any defects and deviations that arise in the technological chain, and determine their impact on the quality of poultry meat. Factors influencing the quality of poultry meat are presented in Fig. 1.

“The influence of negative factors on the quality indicators of poultry meat is classified in the following areas: nutritional and biological value, consumer acceptability, food safety and functional and technical properties” [Gushchin, 2002].

Poultry production and processing involves a series of interrelated steps designed to transform poultry into cook-ready carcasses, trimmed carcasses, or various types of boneless meat products. The acceptability of avian muscle tissue as a food product depends largely on the chemical, physical and structural changes that occur in the muscle during its transformation into meat.

Figure 1 – Classification of factors that can negatively affect the quality indicators of poultry meat during its cultivation, delivery and processing

In poultry production, pre-slaughter factors influence not only the growth of muscle mass, their composition and degree of development, but also determine the condition of the bird at slaughter. Thus, the events that take place immediately before and after the death of the bird significantly affect the quality of the meat.

Biochemical changes in poultry meat have not been studied enough; there is no consensus on the significance and timing of its maturation. However, most studies in recent years in this direction have shown that the ripening process has a positive effect on the quality of the product, improving its organoleptic characteristics.

Post-slaughter changes in poultry meat (rigor mortis, ripening, deep autolysis) occur as in the meat of slaughtered animals, but are characterized by a higher intensity, which is associated with the peculiarities of the morphological and chemical composition of the bird.

The ripening process improves the juiciness, tenderness, aroma and digestibility of meat. This process takes place faster in the pectoral muscles of the bird. The entire process of post-mortem meat modification takes from 3 to 6 days, depending on the fatness: the more plump the carcass, the longer the rigor and ripening take. During ripening, the amount of sulfur-containing amino acids (during the breakdown of proteins), aromatic hydrocarbons, etc. increases.

According to the classification proposed by Fletcher, pre-slaughter factors that influence the quality of meat can be divided according to the time of their influence into two categories: having a long-term or short-term effect. Long lasting influencing factors affect the bird constantly, throughout its entire life - genetic and physiological characteristics, diets and diet, living conditions and past diseases.

Short-term factors affecting the quality of poultry meat operate during the last 24 hours of a bird's life. These include: collection (pre-slaughter holding without feed and water, catching), transportation, maintenance at the slaughterhouse, unloading, fixation on the line and immobilization, stunning and slaughter.

The quality of poultry meat is influenced by a large number of pre-slaughter factors; those that act during the last 24 hours of a bird’s life are especially important. These short-term factors influence carcass yield (weight loss), carcass defects (bruises, dislocations and broken bones), carcass microbiological contamination and muscle metabolic capacity. There is good evidence that stressful collection conditions, such as catching birds and placing them in cages, affect the post-mortem functional properties of muscles. In recent years, problems associated with food poisoning and infection have increased, forcing poultry companies to increasingly focus on the conditions of live poultry to ultimately meet the principle of farm-to-table food safety.

Poultry is processed on mechanized or automated lines. To do this, poultry is transported by overhead or cable conveyors, which are equipped with devices for regulating the speed of movement, which helps to increase the productivity of the poultry processing line.

The poultry processing line consists of several conveyors:

Primary processing;

Waxing (waterfowl only);

Evisceration;

Cooling;

Sorting.

Primary processing of poultry includes all technological operations up to the preparation of carcasses for gutting. The scheme for the primary processing of poultry is shown in Fig. 2.

If the bird is stunned poorly or the slaughter is carried out incorrectly, the blood vessels inside the cavity of the carcass fill with blood and redness of the skin occurs on the surface. Such carcasses are either rejected or sent for industrial processing.

|

Figure 2 - Scheme of primary processing of poultry

Industrial methods of poultry slaughter are based on cutting the carotid artery and jugular vein.

Gutting- the process of removing internal organs, i.e. intestines, offal (liver, heart, gizzard), lungs and kidneys. In industry, evisceration includes removal of the crop, trachea, esophagus, oviduct, testes, longitudinal incision of the abdominal cavity and removal of internal organs, separation of the heart, liver, gizzard, intestines, glandular stomach, lungs, kidneys, and neck.

After gutting, the carcasses are washed, sorted, heat-treated (cooled or frozen) and packaged.

The quality of the resulting meat can vary widely under the influence of natural factors, growing and transportation conditions, pre-slaughter housing of animals, slaughter and primary processing conditions, and refrigerated storage parameters.

After the end of an animal’s life, due to the cessation of oxygen supply, the absence of oxidative transformations and blood circulation, inhibition of synthesis and energy production, accumulation of metabolic end products in tissues and disruption of the osmotic pressure of cells, self-disintegration of intravital systems and spontaneous development of enzymatic processes take place in meat. retain their catalytic activity for a long time. As a result of their development, tissue components decompose, the quality characteristics of meat change (mechanical strength, level of water-binding capacity, taste, color, aroma) and its resistance to microbiological processes.

Meat autolysis is the process of spontaneous changes in the chemical composition, structure and properties of raw meat after the slaughter of an animal under the influence of the meat’s own enzymes.

Figure 3 - Effect of autolysis on meat pH

The change in the properties of meat occurs in a certain sequence in accordance with the main stages of autolysis (fresh meat → rigor mortis → resolution of rigor mortis and maturation → deep autolysis), and its quality indicators differ significantly.

Fresh meat includes meat immediately after the animal is slaughtered and the carcass is cut up (for poultry meat up to 30 minutes). In it, the muscle tissue is relaxed, the meat is characterized by a soft consistency, relatively low mechanical strength, and high water-binding ability. The taste and smell of such meat are not sufficiently expressed. Normal fresh meat has a pH of 7.2. After slaughter, during the process of ripening the meat and the accumulation of lactic and phosphoric acids, the pH in the meat of healthy poultry decreases to 5.6-5.8, in the meat of sick individuals - 6.3-6.5, in state of agony and corpses - 6.8-7.0.

Approximately 3 hours after slaughter, the development of rigor mortis begins, leading to a sharp decrease in water-binding capacity, an increase in mechanical strength, a decrease in pH to 5.5-5.6, and deterioration in color and odor. The meat gradually loses its elasticity, becomes tough and difficult to machine. This meat retains increased rigidity even after cooking. Complete rigor mortis occurs at different times depending on the characteristics of the animal and environmental parameters.

After complete rigor, the resolution of rigor begins: the muscles relax, the strength properties of the meat decrease, and the water-binding capacity increases. However, the culinary characteristics of meat (tenderness, juiciness, taste, smell and digestibility) have not yet reached the optimal level and are revealed with the further development of autolytic processes.

In technological practice no established indicators full maturity of the meat and therefore precise ripening dates. This is explained primarily by the fact that the most important properties of meat do not change simultaneously during ripening. Thus, hardness decreases most noticeably 5-7 days after slaughter (at 0-4°C) and subsequently, although slowly, continues to decrease. Organoleptic indicators reach optimum after 10-14 days. There is no further improvement in smell and taste. A particular method of using meat must correspond to a certain and most favorable level of development of autolytic changes in tissues. The suitability of meat for certain purposes is judged by the properties and indicators that are of decisive importance for this specific purpose.

Autolytic transformations of meat are based on changes in the carbohydrate system, the ATP resynthesis system and the state of myofibrillar proteins included in the contraction system.

Due to the lack of oxygen entering the body, the resynthesis of glycogen in meat after slaughter cannot occur, and its anaerobic decomposition begins, which proceeds along the path of phosphorolysis and amylolysis with the formation of lactic acid and glucose.

The rate of glycolysis can be adjusted: the introduction of sodium chloride into fresh meat suppresses the process; the use of electrical stimulation accelerates. Intense intravital breakdown of glycogen can be caused by stressful situations in animals.

After 24 hours, glycolysis stops due to the depletion of ATP reserves and the accumulation of lactic acid, which suppresses phosphorolysis.

The enzymatic breakdown of glycogen is a trigger for the development of subsequent physicochemical and biochemical processes. The accumulation of lactic acid leads to a shift in the pH of meat towards the acidic side from 7.2-7.4 to 5.4-5.8 resulting in:

The resistance of meat to the action of putrefactive microorganisms increases;

The solubility of muscle proteins decreases (isotope 4.7-5.4), their level of hydration, and the value of water-binding capacity;

Connective tissue collagen swells;

The activity of cathepsins increases (optimum activity - 5.3), causing hydrolysis of proteins in the later stages of autolysis;

The bicarbonate system of muscle tissue is destroyed with the release of carbon dioxide;

Conditions are created for the intensification of color formation reactions due to the transition of divalent iron to ferric iron in myoglobin;

The taste of meat changes;

The process of lipid oxidation is activated.

The accumulation of lactic (and phosphoric) acid, as already noted, has a significant impact on the state of muscle proteins, which in turn determines the technological properties of meat: consistency, water-binding ability, emulsifying and adhesive properties.

At the first stages of maturation, partial dissociation of actomyosin occurs, one of the reasons for which is an increase in the amount of easily hydrolyzed phosphates during this period and, obviously, the influence of tissue proteases.

In the process of long-term ripening of meat, a significant improvement in organoleptic and technological characteristics occurs. In the early stages of autolysis, meat does not have a pronounced taste and smell, which, depending on the storage temperature, appear only on days 3-4 due to the formation of enzymatic breakdown products of proteins and peptides (glutamic acid, threonine, sulfur-containing amino acids), nucleotides (inosine, hypoxanthine etc.), carbohydrates (glucose, fructose, pyruvic and lactic acid), lipids (low molecular fatty acids), as well as creatine, creatinine and other nitrogenous extractives.

Currently, the issue of targeted use of raw materials, taking into account the progress of autolysis, is of particular importance, since the proportion of animals entering processing from industrial complexes, in which, after slaughter, significant deviations from the usual in the development of autolytic processes are found in the muscle tissue. Accordingly, a distinction is made between meat with high final pH (DFD) and exudative meat (PSE) with low pH values.

Poultry meat matures intensively, which improves the taste and digestibility of this product. Duck meat matures faster than chicken and geese meat.

Main species

Chickens - the most common type of poultry. Depending on the productivity, chickens are divided into meat, egg-laying and general use (meat-egg-laying) chickens.

Meat chickens(cornishes, brama, langshan) are characterized by large live weight: roosters - 3.5-5.5 kg, chickens - 3-4.5 kg, as well as rapid growth, precocity, good muscle development with a small content of connective tissue. Their meat yield is high - up to 70%.

Much attention is paid to raising broilers – meat chickens. They are distinguished by high early maturity and at the age of 60 days reach a live weight of 1.6 kg or more. Broiler meat - chickens is tender, juicy, has high taste and dietary advantages. It contains about 20% protein and 5.2-12.3% fat. Broiler chickens are sold chilled.

Egg-laying chickens (Russian White, New Hampshire, Leghorn, Poltava, White Moscow) are small in size and live weight: roosters - 2.7-3 kg, chickens - 1.8-2.2 kg. Egg production – 220-260 eggs per year.

Common chickens (Zagorskie, Plymouthrock, Livenskie, Moscow black) are larger than egg-laying chickens, but their eggs are smaller. Live weight of roosters – 3.5-4 kg, chickens – 2.5-3 kg. They fatten well and grow quickly.

Geese - have large sizes and large mass: ganders - 6-12 kg, geese - 5-10 kg. The most common meat breeds of geese are: Arzamas, large raw, Kholmogory, Tula, Lithuanian.

Ducks – grow quickly and reach a weight of 2 kg at 8 weeks of age. In our country, several breeds of ducks are bred - Peking, Moscow white, mirror. Based on productivity, they are divided into meat, egg-laying and general-purpose meat breeds.

Turkeys - the largest type of poultry, they are raised for meat. The weight of turkeys reaches 12-16 kg, turkeys - 7-9 kg. The slaughter yield of fattened turkeys is 85-90%. Turkey meat has high taste and good digestibility. The most common breeds of turkeys are North Caucasian Bronze, Bronze Broad-breasted, and Beltsville.

Guinea fowl less common than other types of poultry. They are small in size and have a live weight of 1.6-2.2 kg. Guinea fowl meat resembles the meat of game birds, but is much more tender and fattier. Pearl and blue breeds of guinea fowl are bred.

By type and age distinguish between young poultry meat (carcasses of chickens, broilers - chickens, ducklings, goslings, turkey poults and guinea fowl), and adult (carcasses of chickens, ducks, geese, turkeys, and guinea fowl).

Carcasses of young birds have a non-ossified (cartilaginous) keel of the sternum, a non-roughened beak, the lower part of which easily bends, and delicate elastic skin. Carcasses of chickens, broilers - chickens, turkey poults and guinea fowl have smooth and tightly fitting scales on their legs, underdeveloped spurs in the form of tubercles; Ducklings and guinea fowl have delicate skin on their legs.

Carcasses of adult birds have an ossified (hard) keel of the sternum and a keratinized beak. The legs of chickens, turkeys and guinea fowl carcasses have rough scales, the legs of ducks and geese have rough skin, and roosters and turkeys have hard spurs on their legs.

TO half gutted include carcasses from which the intestines with the cloaca and the full crop have been removed.

Gutted- carcasses from which all internal organs, head to the 2nd cervical vertebra, neck (without skin) at the level of the shoulder joints, legs to the tarsal joint or below it, but no more than 2 cm. The visceral fat of the lower abdomen is not removed. Sales of gutted carcasses with lungs and kidneys are allowed.

Gutted carcasses with a set of giblets and neck include gutted bird carcasses, in the abdominal cavity of which a set of processed giblets (heart, liver, gizzard) and neck are inserted.

According to thermal state

carcasses of all types of poultry (except old roosters) are divided into 2 categories - 1 and 2. The fatness category is determined by the degree of development of muscle tissue and the prominence of the sternum crest (keel), the amount of subcutaneous fat deposits and the quality of surface treatment.

Muscle tissue is well developed in carcasses of all types of poultry, and in broiler chickens it is very well developed.

The shape of the breast of broiler carcasses - chickens, hens, turkeys and guinea pigs - is round. The keel of the breast bone does not stand out, except in the carcasses of chickens, turkey poults, and guinea pigs, in which it may stand out slightly.

Deposits of subcutaneous fat on the carcasses of chickens and guinea pigs - in the lower abdomen and on the back in the form of an intermittent strip; broilers - chickens - only in the lower abdomen; ducklings, goslings and turkey poults - on the chest and belly; chickens and turkeys - in the abdomen, on the chest and in the form of a continuous stripe on the back; ducks and geese cover the whole carcass, except for the legs and wings, but in geese they are more significant; guinea fowl - on the stomach and in the form of an intermittent strip on the back.

In terms of the quality of post-mortem processing, carcasses must meet the following requirements: well bled, properly dressed, with clean skin free of feathers, fluff, stumps and hair-like feathers, wax, scratches, tears, stains, bruises and intestinal remains.

In gutted carcasses, the mouth and beak are cleaned of food and blood, and the legs are free of dirt and limescale build-up. Single stumps and light abrasions are allowed, no more than two skin tears 1 cm long each, but not on the fillet; slight desquamation of the epidermis of the skin.

Muscle tissue is developed satisfactorily, except for broilers - chickens, in which it is developed quite satisfactorily. The keel of the sternum may stand out, the pectoral muscles with the crest of the sternum form an angle without depressions on its sides.

Deposits of subcutaneous fat are insignificant: in the carcasses of chickens, hens, turkeys and poults - in the lower back and abdomen; ducks, ducklings and geese - on the chest and belly; goslings - on the stomach; guinea fowl and guinea fowl - only on the lower abdomen. With quite satisfactorily developed muscle tissue, there may be no fat deposits.

Carcasses of old roosters with spurs larger than 1.5 cm, regardless of fatness, are classified in category 2.

On the surface of category 2 carcasses, a small number of stumps and abrasions are allowed, no more than three skin tears up to 2 cm long each, peeling of the epidermis of the skin, but not sharply deteriorating the marketable appearance of the carcass.

Poultry carcasses that meet the requirements of category 1 in terms of fatness, and the requirements of category 2 in terms of processing quality, are classified as category 2.

The meat of poultry carcasses is packaged in accordance with GOST 21784 - 76. Carcasses of all types of poultry can be sold individually in plastic film bags (under vacuum or without vacuum) or without packaging, but in this case paper is placed between the rows of carcasses. The legs are separated from semi-gutted carcasses packed in plastic film bags.

Each unpackaged poultry carcass must be marked (electoral stamp or paper label) confirming the fatness category.

Carcasses of category 1 are marked with a pink label, and carcasses of category 2 are marked with a green label. Labels indicating the abbreviated name of the republic, the words “Veterinary inspection”, enterprise number and fatness category are pasted on one of the legs; semi-gutted carcasses - below the tarsal joint, gutted - above the tarsal joint.

Poultry carcasses are not subject to individual branding if the polymer bags in which they are packaged or the label inserted into the bag bear a marking indicating the name of the manufacturer, its trademark, the type of bird, the category and method of processing the carcasses, and the words “Veterinary Inspection.” ", prices 1 kg, current standard.

Poultry carcasses are packaged in metal, wooden and corrugated cardboard boxes separately by type, fatness category and processing method. The bottom and walls of the boxes are lined with wrapping paper, and the carcasses are covered with its protruding ends. If each bird carcass is packed in a bag made of polymer material, then the box is not lined with paper, film or parchment. Poultry carcasses are placed in a box in one row in height. Bird carcasses of the same species, fatness category and processing method are placed in a box. Frozen poultry carcasses that are not packaged in plastic bags must be separated by spacers made of vegetable parchment. Boxes made of corrugated cardboard are used for the production of poultry meat only in a frozen state. Depending on the type of bird, a certain number of carcasses (in pieces) are placed in each box: hens, chicks and guinea fowl - up to 25, geese and ducklings - up to 20, geese and goslings - up to 6, turkeys and poults - up to 5. Net weight Products packed in wooden boxes should weigh no more than 30 kg, and products packed in polymer and cardboard boxes should weigh no more than 15 kg.

The labeling indicates the name of the manufacturer, its subordination and trademark, the number and year of GOST approval, the number of carcasses, net and gross weight, processing date.

Symbols for poultry carcasses species and age – C – chickens, CB – broilers – chickens, K – chickens, UM – ducklings, U – ducks, GM – goslings, G – geese, IM – turkey poults, I – turkeys, SM – guinea fowl, S – guinea fowl; processing method – E – semi-gutted, EE – gutted, P – gutted with a set of giblets and neck; fatness categories – 1 -1 category, 2 – 2 category; T - does not correspond in terms of fatness to the first and second categories (skinny). If the bird is packaged, then the letter F is placed before the designation of the fatness category. Thus, the F2U marking means: packaged ducks of the 2nd category.

In addition to the packaging indicated on the end, a label is placed in the box indicating the name of the poultry processing plant, the type and category of poultry, the date of slaughter, the number of carcasses and net weight, the name or number of the packer.

General requirements for labeling poultry meat are set out in clause 4.2; clause 4.3 GOST R 51074 – 2003 “Food products. Information for the consumer. General requirements".

Meat in carcasses (not packaged in consumer packaging):

Type and age (for example, “hens” or “chicks”, “ducks” or “ducklings”, etc.) of the bird;

Amount;

Net and gross weight;

The word "Gosvetnadzor";

Name of country and place of origin;

Protected with a film of... (if the carcasses are covered with film-forming agents);

Food additives, flavorings, biologically active food additives, ingredients of products of non-traditional composition (if used);

Poultry meat in carcasses, half carcasses, in the form of parts of carcasses, packaged in consumer packaging:

Name of the product (carcasses, half carcasses, stews, legs, necks, wings, etc.);

Name and location of the manufacturer [legal address, including country, and, if different from legal address, address(es) of production(s)] and organization in Russian Federation, authorized by the manufacturer to accept claims from consumers on its territory (if any);

Manufacturer's trademark (if available);

Method of processing carcasses (gutted, semi-gutted, gutted with a set of giblets and neck);

Protective coatings, preservatives, food products of non-traditional composition;

The word “Gosvetnadzor” (for whole carcasses);

Net weight (for carcasses, indicate the net weight in each unit of consumer packaging or the total net weight of packaged carcasses in each unit of transport container);

The nutritional value;

Manufacturer date and packaging date;

Shelf life and storage conditions;

Designation of the document in accordance with which the product is manufactured and can be identified;

Information about confirmation of conformity.

Boned poultry meat (pieces and mechanically separated, including frozen in blocks):

Product name, including the type and age of the bird;

The nutritional value;

Variety (if available);

Name and location of the manufacturer [legal address, including the country, and, if it does not coincide with the legal address, the address(es) of production(s)] and organization in the Russian Federation authorized by the manufacturer to accept claims from consumers on its territory (if any);

Manufacturer's trademark (if available);

Thermal state (chilled, light frozen or deep frozen);

Manufacturer date and packaging date;

Shelf life and storage conditions;

Net and gross weight;

Designation of the document in accordance with which the product is manufactured and can be identified;

Information about confirmation of conformity.

Meat of all types of poultry is subject to mandatory branding with veterinary brands and stamps in accordance with the requirements of the Instructions for Veterinary Branding of Meat. Meat branding is carried out only after a veterinary and sanitary examination.

To brand poultry meat, an oval-shaped veterinary brand is used.

The oval-shaped veterinary mark has three pairs of numbers in the center: the first of which indicates the serial number of the republic within the Russian Federation, territory, region, Moscow, St. Petersburg; the second is the serial number of the district (city) and the third is the serial number of the institution, organization, enterprise. At the top of the stamp there is the inscription “Russian Federation”, and at the bottom - “Gosvetnadzor”. The oval veterinary mark confirms that the veterinary and sanitary examination of the meat has been carried out in full and the product is released for food purposes without restrictions.

At meat and poultry plants and poultry factories, you can use an electric brand without a rim with the numbers 1 or 2 (depending on the category), which is placed on the outer side of the bird’s leg.

When packing carcasses in plastic film bags, the type and category of poultry meat is marked directly on the bags using a printing method.

In veterinary examination laboratories, poultry carcasses are marked with one mark on the neck or outer surface of the thigh.

At meat and poultry plants, poultry plants and poultry farms, an electric mark is placed on the outer surface of the lower leg: for carcasses of chickens, chickens, ducklings, guinea fowl - on one leg; for carcasses of ducks, goslings, geese, poults and turkeys - on both legs.

Poultry carcasses subject to industrial processing are marked with an electric mark “p” in the back area.

On the carcasses of all types of birds recognized by the results of a veterinary and sanitary examination as unsuitable for food purposes, at least 3 - 4 imprints of a veterinary stamp with the inscription “Scrap” are placed.

Oval-shaped stamp for branding poultry meat (dimensions 25x40 mm; rim width 1 mm; letter height 3 mm; number height 6 mm). Electric brands for poultry carcasses at meat processing plants, poultry processing plants, poultry farms (height of letters and numbers 20 mm)

In the store, chilled and frozen poultry meat is stored in boxes, which are placed in stacks on shelves.

1 2 P

1 2 P

Figure 4 - Branding of poultry meat

Chilled poultry meat should be stored at a temperature of 0-2ºС and a relative air humidity of 80-85% for no more than 5 days, at 0-6º - up to 3 days, and when the temperature rises to 8ºС - only for a day.

The shelf life of frozen poultry meat at temperatures below 0ºС and relative air humidity of 85-95% is up to 5 days, at 0-6ºС - up to 3 days, and at temperatures not higher than 8ºС - up to 2 days. Packaged poultry is stored in the store for no more than a day.

IN retail sales We also receive imported poultry - chickens, broiler chickens, chickens, turkeys, ducks, geese. According to its thermal state, it can only be frozen, and according to post-slaughter processing, it can only be gutted. A set of processed by-products (neck without skin, heart, liver, stomach) in a plastic film bag is placed in the abdominal cavity of the bird.

The quality of imported poultry is determined in accordance with the technical conditions of the supplier country, which are confirmed by the Ministry of Trade of the Russian Federation. The shelf life of poultry meat, depending on its species and temperature parameters, is indicated in Table 2.

Table 2 - Shelf life of poultry meat depending on its species and temperature parameters

| Bird species | Shelf life, in months, at temperature | |||||||

| minus 12 0 C | minus 15 0 C | minus 18 0 C | minus 25 0 C | |||||

| Unpacked carcasses | Carcasses packed in film | Unpacked carcasses | Carcasses packed in film | Unpacked carcasses | Carcasses packed in film | Unpacked carcasses | Carcasses packed in film | |

| Chickens, turkeys, guinea fowl | 5 | 8 | 7 | 10 | 10 | 12 | 12 | 14 |

| Chickens, broilers - chickens, turkey poults, guinea fowl | 4 | 8 | 6 | 10 | 8 | 12 | 11 | 14 |

| Geese, ducks | 4 | 6 | 5 | 8 | 7 | 10 | 11 | 12 |

| Goslings, ducklings | 3 | 6 | 4 | 8 | 6 | 10 | 10 | 12 |

6 Adulteration of poultry meat

In recent years, the range and volumes of meat sales in Russia have increased significantly. On the meat market, which is in stable demand among consumers, various types are presented, and it is sometimes difficult for the buyer to choose a quality product from this variety. The choice of natural meat is quite large, so the meat distributor is tempted to fake or increase the volume of his sales by diluting the meat with water, blood, air, etc.

Today, there are problems with conducting a comprehensive examination of the authenticity of all types of meat supplied to Russian markets.

When conducting an examination of the authenticity of meat, the following research goals can be achieved:

Identification of meat type;

Methods of falsification and methods of their detection.

When conducting an authenticity examination in order to identify the type of meat, the expert must determine for himself the range of tasks to be solved and the methods at his disposal.

Meat is a product consisting of muscle tissue of warm-blooded herbivores and birds, which has undergone technological processing and branding.

Meat is identified by species, sex, age, fatness and thermal state of the warm-blooded herbivore.

The general identifying features of the assortment of meat products include mainly organoleptic indicators: shape, color, taste, smell, consistency, internal structure.

Poultry meat is marketed in the form of carcasses, half carcasses, legs, breasts, and fillets. At the same time, the shape of carcasses and half-carcasses has characteristic morphological features for each type of bird.

The shape of carcasses and half-carcasses, together with their morphological characteristics and the color of muscle tissue, as well as fat, allows one to reliably identify the type of animal and its age.

The color of the surface and the color of the muscle tissue on the cut make it possible to determine the type of meat depending on the type and age of the animal. The color of the surface depends on the degree of development of subcutaneous fat.

The color of muscle tissue on a section is a reliable identifying sign of the type of animal and its age. The meat of young animals is lighter in color than that of old ones.

For meat freshness- a complex quality indicator, characterized by a set of individual indicators, among which the “surface condition” indicator also plays an important role. Poultry meat is also identified by marking and veterinary branding (see paragraph 5)

Assortment falsification is most often carried out by replacing one type of meat with another, less nutritionally valuable type, as well as partial substitution of meat with offal or dairy products (mainly milk powder), or vegetable raw materials (starch, flour, cereals, vegetables). In table Table 3 presents the main methods of falsifying poultry meat.

Currently, such exotic poultry species as pheasants, quails and partridges have appeared in the retail trade. Their price is slightly higher than that of chickens and broiler chickens. Buyers are also attracted by the unusual nature of the bird. There are cases of falsification of gutted pheasants, partridges and quails by selling ordinary chickens instead.

Visual inspection. Veterinary examination. Microscopy.

Checking the degree of bleeding

chilled

When releasing loose goods, the body kit

buyers

Poultry falsification also occurs due to inaccurate information about the country or place of origin. For example, sometimes domestic chickens are passed off as imported (or vice versa), or chickens that were re-exported from veterinarily unfavorable countries, the import of poultry from which is prohibited in Russia, are passed off as domestic or imported from permitted countries. If cases of such falsification are detected, the State Veterinary Service authorities impose a ban on the sale of such products.

It is possible to detect such assortment falsification using organoleptic methods by determining color, taste and smell.

Qualimetric falsification is carried out with the aim of selling meat products of reduced quality at the price of high-quality products of the same type and name or at a lower price to ensure their price competitiveness, although even the reduced price of such products can be high for their very low quality. For example, the sale of meat of questionable freshness at the lower price limit for standard products.

Falsification can be carried out by partially replacing meat with other less nutritionally valuable raw materials of animal and plant origin. The most common counterfeit substitutes include water and various fillers.

Water or a water-salt solution diffuses into the meat during soaking or is injected into the muscle tissue or under the skin of the poultry carcass, and the appearance of the carcass is improved by the appearance of light skin color and the appearance of good fatness.

Adulteration of meat with water or blood. Widespread high-quality falsification of meat. There are several ways.

1 Meat is placed in water for several hours and its weight can increase up to 25%.

2 Water is injected into frozen meat using a syringe or into the blood into the voids formed during freezing. Water is partially colored by blood, and blood is an ideal component for such adulteration, and freezes, and the result is a single frozen whole. When selling such frozen meat, it is practically impossible to distinguish artificially injected and frozen blood from regular blood. Then, when the consumer begins to defrost such meat at home, the color of the water becomes more red.

3 They freeze water onto the carcass. To do this, frozen carcasses of meat are poured with water on top. The water freezes and then the ice is sold along with the meat at the price of meat.

To extend the shelf life of meat, various antibiotics are introduced into it. This allows you to significantly extend the shelf life of meat. Abroad, antibiotics are added to water that is frozen, for example, on bird carcasses, chicken legs, etc. Therefore, as many experts note, even flies do not land on such products.

Recently, meat inflation has become widespread in the sale of chickens.

This falsification occurs for purely commercial reasons, since inflation gives the meat a more plump, beautiful, appetizing appearance, making it easier to sell for a higher price.

There is no doubt that inflated meat cannot cause much harm to the consumer if the meat is sold by weight, but this falsification is intended to fake the appearance of the meat. In addition, inflation is almost always practiced through a tube with the mouth, when, therefore, it is possible to introduce into the meat a wide variety of representatives of the bacterial flora of saliva, not excluding spirochetae palida and tubercle bacilli. In addition, inflated meat is fragile: it very soon begins to deteriorate in its entire thickness at the same time, which is understandable if we take into account the mass of saprophytes that is driven into the meat along with atmospheric air.

In many markets, chickens are sold not by weight, but by size and appearance. Therefore, meat traders insert a needle under the skin of chickens, or into the muscle tissue of the breast and inflate with a pump. As a result, the skinny chicken looks well-fed. It is quite easy to distinguish such counterfeits. When palpating a chicken carcass, the meat does not have a dense consistency, but a fluid, easily moving mass.

To give poultry carcasses a yellow color (meaning well-fed and fatty), meat traders rub carrots or carrot juice. Sometimes poultry carcasses can be rubbed with other yellow dyes, for example, saffron, food dyes.

Probably many buyers have noticed that there are no more “blue” hens and chickens in our markets. Sellers simply treat chickens with bleach. To do this, place the bird carcass in a boiling solution of baking soda for 1-2 seconds. Soda, getting into the subcutaneous layer, increases its volume and the skin becomes opaque and muscle tissue is not visible. Thus, the skin color becomes whiter, and a small layer of subcutaneous fat gives the carcass a noble yellow color.

Acceptance of products is usually carried out according to individual indicators of their quality, specified in the normative and technical documentation. To determine these indicators, only metrological certified methods approved by Gosstandart are used.

Sampling of products and their preparation for laboratory testing must be approved by Gosstandart.

The rules for accepting poultry meat are carried out in accordance with GOST 28825 - 90.

Poultry meat is taken in batches. A batch is considered to be poultry meat of the same type, category and processing method, one date of production or several nearest dates for frozen meat, issued with one certificate (in accordance with the appendix) of quality and a veterinary certificate.

The volume of the batch is no more than the carrying capacity of one railway car.

When selling poultry meat in areas of production or storage, it is allowed to place a quality stamp on the invoice instead of a quality certificate.

Appearance and marking of transport containers for compliance with regulatory requirements -technical documentation checked on each unit of transport container in the batch.

The quality of products in unmarked, unclearly marked or defective containers is checked separately, and the results apply only to products in these containers.

To assess products for compliance with the requirements, regulatory and technical documentation, a random sample of undamaged transport containers and carcasses is selected in accordance with the requirements of Table 4.

Table 4 - Sampling of poultry meat from a batch

| Batch volume in transport packaging units | Sample volume in units of transport packaging (5% of the batch) | Number of selected (carcass) product units | |||

| Including those subject to defrosting | |||||

| Chickens, chicks, broiler chicks, ducks, ducklings, guinea fowl, guinea fowl, quails | Geese, goslings, turkeys, poults | ||||

| Up to 20 incl. | 1 | 4 | 4 | 4 | 2 |

| St. 20"100" | 1-5 | 8 | 4 | 5 | 3 |

| "100"400" | 5-20 | 16 | 8 | 6 | 3 |

| "400"800" | 20-40 | 25 | 12 | 10 | 5 |

| "800"1500" | 40-75 | 35 | 17 | 15 | 7 |

| »1500 or more | 75 or more | 45 | 21 | 20 | 9 |

Control of the net weight of products for compliance with the weight indicated in the transport labeling is carried out for each transport unit of the sample container selected in accordance with the requirements of the table.

In case of discrepancy, acceptance is carried out based on the actual net weight of all products.

Selected poultry carcasses are assessed according to the following indicators: smell (if in doubt, the taste of meat and the aroma of the broth), fatness (the state of the muscular system and the presence of fat deposits), the degree of feathering, the condition and type of skin, the condition of the skeletal system, the shape, weight and temperature of the carcass.

If unsatisfactory results for the odor indicator are obtained, the batch is not subject to acceptance.

If unsatisfactory results are obtained for at least one of the other indicators by more than 25 % selected carcasses are repeated tests on a double number of carcasses from the same sample.

The results of repeated tests are applied to the entire batch.

If there is a disagreement in assessing the quality of poultry meat, chemical, microscopic, bacteriological and histological analyzes are carried out according to GOST 7702.1 and GOST 23441.

A sample quality certificate is presented in Appendix A.

Poultry meat must be produced in accordance with the requirements of GOST 21784-74 “Poultry meat. Technical conditions" according to technological instructions for the production of poultry meat in compliance with sanitary rules approved in the prescribed manner.

Depending on the age of the bird, meat is divided into meat of young and adult birds.

Young poultry meat includes carcasses of chickens, broilers - chickens, ducklings, goslings, turkey poults and guinea fowl with a non-ossified (cartilaginous) keel of the sternum, a non-keratinized beak, and snowy elastic skin on the carcass. On the legs of chicken carcasses, broiler chickens, turkey poults and guinea fowl there are smooth, tight-fitting scales and spurs that are not developed in the form of tubercles: ducklings and goslings have delicate skin.

The meat of adult poultry includes the carcasses of chickens, ducks, geese, turkeys and guinea fowl with an ossified (hard) keel of the breast bone and a keratinized beak. The legs of carcasses, chickens, turkeys and guinea fowl have rough scales, while the carcasses of ducks and geese have rough skin. The spurs of roosters and turkeys are hard.

The weight of the cooled semi-gutted carcass of a young bird must be no less than that indicated in Table 5.

Table 5 - Requirements for the weight of poultry carcasses

It is allowed to produce chicken carcasses weighing semi-gutted from 400 to 480 g, according to fatness and processing, meeting the requirements of the standard in quantities not exceeding 15% of the total number of carcasses in the batch.

Poultry carcasses are divided into semi-gutted, gutted and gutted with a set of giblets and neck.

Gutted - carcasses from which the intestines with cloaca, full crop, and oviduct (in females) have been removed.

Gutted - carcasses in which all internal organs, the head (between the second and third cervical vertebrae) have been removed; neck (without skin) at the level of the shoulder joints, legs to the tarsal joint or below it, but not more than 20mm. The visceral fat of the lower abdomen is not removed.

It is allowed to release gutted carcasses with lungs and kidneys.

Gutted carcasses with a set of giblets and neck - gutted carcasses in the cavity of which a set of processed giblets (liver, heart, gizzard) and neck are inserted, packed in polymer film, cellophane or parchment.

Depending on the temperature in the thickness of the pectoral muscles, carcasses are divided into cooled (temperature no higher than plus 25 0 C), chilled (temperature from 0 to plus 4 0 C), frozen (temperature no higher than minus 8 0 C).

Based on the fatness and quality of processing, poultry carcasses of all types are divided into two categories: first and second.

In terms of fatness, carcasses of all types of birds must meet the requirements specified in the table. 6.

Poultry carcasses must be well bled, clean, free of feathers, down, stumps and hair-like feathers, wax (for waterfowl carcasses undergoing waxing), scratches, tears, stains, bruises, intestinal remains and cloaca.

In semi-gutted carcasses, the mouth and beak must be cleaned of food and blood, the legs must be cleaned of dirt, limescale and deposits.

Table 6 – Requirements for the condition of bird carcasses

| Bird species | Characteristics of fatness (lower limit) | |

| First category | Second category | |

| Chickens | The carcass muscles are well developed. Deposits of subcutaneous fat in the lower abdomen and in the form of an intermittent strip on the back. The keel of the sternum is slightly prominent. | The carcass muscles are developed satisfactorily. The keel of the sternum stands out, the pectoral muscles form an angle without depressions. Slight deposition of subcutaneous fat in the lower back and abdomen. Deposits of subcutaneous fat may be absent when the muscles of the carcass are quite satisfactorily developed. |

| Broiler chickens | The muscles of the carcass are very well developed. The breast shape is round. Deposits of subcutaneous fat in the lower abdomen. The keel of the sternum is not prominent | The muscles of the carcass are developed quite satisfactorily. The pectoral muscles with the keel of the sternum form an angle without depressions. Subcutaneous fat deposits may be absent. The keel of the sternum may be prominent |

| Chickens | The carcass muscles are well developed. The breast shape is round. Deposits of subcutaneous fat on the chest, abdomen and in the form of a continuous strip on the back. The carina of the pectoral hand is not prominent. | The carcass muscles are developed satisfactorily. The breast shape is angular. Minor deposits of subcutaneous fat in the lower abdomen and back. The absence of fat deposits is allowed if the muscles are quite satisfactorily developed. The carina of the pectoral carus stands out |

| Ducklings | The carcass muscles are developed satisfactorily. Small deposits of subcutaneous fat on the chest and abdomen. The absence of fat deposits is allowed if the muscles are quite satisfactorily developed. The keel of the sternum may be prominent | |

| Ducks | The carcass muscles are well developed. Deposition of subcutaneous fat on the chest, abdomen and back. The keel of the sternum is not prominent | The carcass muscles are developed satisfactorily. Minor deposits of subcutaneous fat on the chest and abdomen. It is acceptable to have no fat deposits on the abdomen and back with quite well-developed muscles. The carina of the pectoral carus stands out |

| Goslings | The carcass muscles are well developed. Deposition of subcutaneous fat on the chest and abdomen. The keel of the sternum is not prominent | The carcass muscles are developed satisfactorily. The breast shape is angular. Minor deposits of subcutaneous fat on the abdomen. The absence of subcutaneous fat is allowed if the carcass muscles are quite satisfactorily developed. The carina of the pectoral carus stands out |

| Geese | The carcass muscles are well developed. Significant deposits of subcutaneous fat on the chest, abdomen, under the wing and on the back. The keel of the sternum is not prominent | The carcass muscles are developed satisfactorily. The breast shape is angular. Minor deposits of subcutaneous fat on the chest and abdomen. The keel of the pectoral hand may stand out. |

| Turkey poults | The carcass muscles are well developed. Deposits of subcutaneous fat on the chest and abdomen. The keel of the sternum may be slightly prominent | The carcass muscles are developed satisfactorily. The keel of the sternum stands out, the pectoral muscles form an angle without depressions. Minor deposits of subcutaneous fat in the lower back and abdomen. Deposits of subcutaneous fat may be absent even if the muscles of the carcass are quite satisfactorily developed. |

| Turkeys | The carcass muscles are well developed. The breast shape is round. Deposits of subcutaneous fat on the chest, abdomen and in the form of a continuous strip on the back. The keel of the sternum is not prominent | The muscles of the carcass are developed satisfactorily, the shape of the chest is angular. Small deposits of subcutaneous fat on the back and abdomen. The absence of fat deposits is allowed if the muscles are quite satisfactorily developed. The keel of the sternum stands out |

| Crown Princes | The carcass muscles are well developed. Minor deposits of fat in the lower abdomen and in the form of an intermittent strip on the back. The keel of the sternum is slightly prominent | The carcass muscles are developed satisfactorily. The pectoral muscles with the keel of the sternum form an angle without depressions. Small deposits of fat on the lower abdomen. The absence of fat deposits is allowed if the muscles are quite satisfactorily developed. The keel of the sternum may be prominent. |

| Guinea fowl | The carcass muscles are well developed. The breast shape is round. Deposits of subcutaneous fat on the abdomen in the form of an intermittent strip on the back. The keel of the sternum is not prominent | The carcass muscles are developed satisfactorily. The breast shape is angular. Small deposits of fat on the lower abdomen. The absence of fat deposits is allowed if the muscles are quite satisfactorily developed. The keel of the sternum stands out. |

Note. Poultry carcasses of all types that do not meet the fatness requirements of the second category are classified as lean.

Allowed:

On bird carcasses of the first category - single stumps and light abrasions, no more than two skin tears 1 cm long each (not on the chest), slight desquamation of the epidermis of the skin;

on poultry carcasses of the second category - a small number of stumps and abrasions, no more than three skin tears up to 2 cm long each, desquamation of the epidermis of the skin, which does not sharply worsen the presentation of the carcass.

Poultry carcasses that meet the requirements of the first category in terms of fatness, and the requirements of the second category in terms of processing quality, are classified as the second category.

The following poultry carcasses are not allowed for sale in retail and public catering networks, but are used for industrial processing: those that do not meet the second category in terms of fatness and quality of processing; curvature of the back and chest bone; with scratches on the back; frozen more than once, with flowing pigmentation, except for turkeys and guinea fowl.

Carcasses of old roosters corresponding to the first category, but having spurs longer than 15 mm, are classified as the second category.

The freshness of meat is determined by the results of organoleptic evaluation. Organoleptic indicators must meet the requirements presented in Table 7.

Poultry meat, classified as meat of questionable freshness based on the results of organoleptic evaluation, is subjected to chemical and microscopic analysis.

The meat and fat of poultry carcasses whose organoleptic characteristics do not meet the standard requirements for fresh carcasses are subjected to chemical studies.

GOST 7702.1-74 provides for the determination of: indicators of ammonia and ammonium salts; peroxidase activity; amount of volatile fatty acids; acid and peroxide numbers of fat (Table 8).

During microscopic analysis, the number of bacteria and the degree of breakdown of muscle tissue are determined by microcopying smears - fingerprints.

Harmful and toxic substances in poultry meat should not exceed the limits specified in the table. 9. Microbiological indicators must meet the requirements of Table 10.

Table 7 - Indicators characterizing the freshness of poultry meat

| Index | Characteristics of poultry carcasses | ||

| fresh | of questionable freshness | stale | |

Appearance and color bird beak |

Glossy |

No gloss | No gloss |

| mucous membrane | Brilliant | No shine | No shine |

| poultry oral membranes | pale pink, slightly moisturized | pinkish-gray color, slight mucus, traces of mold | Gray in color, covered with mucus and mold |

| bird eyeball | convex, shiny cornea | Not convex, cornea without shine | Collapsed, cornea without shine |

| poultry carcass surface | dry, whitish-yellow with a pinkish tint | Moist in places, sticky under the wings, in the groins and folds of the skin, whitish-yellow in color with a gray tint | Covered with whitish-yellow mucus with a gray tint, with dark and greenish spots in places |

| Subcutaneous internal adipose tissue of poultry | Pale yellow or yellow color | Yellowish-white with a gray tint | |

| serous membrane of the abdominal cavity | Wet, shiny | No shine, sticky, possible traces of mold | Covered with slime and mold |

| Muscles in section | Slightly moist, pale pink | Moist, slightly sticky, darker in color than fresh | Wet, sticky, darker in color with a brownish tint |

| Consistency | The muscles are dense, elastic, when pressed with a finger, the resulting hole quickly levels out | The muscles are less dense and elastic than fresh ones, the hole from finger pressure is leveled out slowly and not completely | The muscles are flabby, the dimple from finger pressure does not level out |

| Smell | Specific, characteristic of fresh meat | Musty in the chest - abdominal cavity | Putrefactive, most pronounced in the abdominal cavity |

| Broth clarity and smell | Transparent, fragrant | Transparent or cloudy | Muddy with big amount flakes, with a strong unpleasant odor |

Table 8 - Physico-chemical indicators of the quality of poultry meat (carcasses)

| Index | Meat (carcasses) | ||

| fresh | of questionable freshness | stale | |

|

ammonium salts |

Greenish-yellow extract colors, transparent or slightly |

Exhaust intensively yellow, sometimes with an orange tint, observed significant turbidity with the formation of a thin layer of sediment within 10...20 minutes |

The hood is yellowish-orange, fast formation of large flakes that precipitate |

| Peroxidase (except waterfowl and chicken) | The hood has a blue-green color that changes within 1... 2 minutes. brown-brown |

- | Hood without a specific blue-green color or immediately brown appears Brown color |

| No more than 4.5 | 4,5... 9 | More than 9 | |

Acidic |

Up to 1 | 1 ...2.5 - chilled chickens; 1... 2 - chilled geese; 1... 3 - chilled ducks and turkeys; 1... 1.6 - frozen poultry carcasses |

More than 2.5 - chilled chickens; 2 - chilled geese; 3 - chilled ducks and turkeys; 1.6 - frozen poultry carcasses |

Peroxide number, |

No more than 0.01 | 0.01 ...0.04 - chilled chickens; 0.01 ...0.1 - chilled geese, ducks, turkeys; 0.01... 0.03 - frozen poultry carcasses | More than 0.04 - chilled chickens; 0.1 - chilled geese, ducks, turkeys; 0.03 - frozen poultry carcasses |

Table 9 - Hygienic requirements for the safety and nutritional value of poultry meat

| Index, product group | Indicators | Acceptable levels mg/kg, no more |

Note |

| 1 | 2 | 3 | 4 |

1.1.9. poultry meat, including semi-finished products, chilled, frozen, frozen (all types of poultry for slaughter, game birds) |

Toxic elements: |

||

Antibiotics<*>: Levomycetin Tetracycline group Bacitracin |

not allowed not allowed not allowed not allowed |

except wild < 0,01 ед/г < 0,5 ед/г < 0,02 ед/г |

|

Pesticides<**>: Hexachlorocyclohexane (alpha -, beta -, gamma - isomers) DDT and its metabolites |

|||

Radionuclides: strontium-90 |

Table 10 - Microbiological indicators

Defect - failure to comply with a specified or expected requirement concerning an object, as well as a requirement related to its safety (ISO 8402-94).

Defects in poultry carcasses arise as a result of violations of technological processing, as well as non-compliance with storage conditions and periods, and reduce the quality of poultry meat. The characteristics of technological defects are determined by GOST 16367-86.

Namin on a bird carcass is a defect that occurs on the keel of the sternum, characterized by thickening or swelling of the skin and subcutaneous muscle layer on the bird carcass.

Poultry carcass is the presence of areas on the chest and abdominal parts of the bird carcass with erased feather edges or damage to the upper layers of skin.

Pecking on a bird carcass is damage to the skin of a bird carcass that occurs during pecking without the presence of an inflammatory process.

Dermatitis on a poultry carcass is an inflammation of the skin.

Pinpoint hemorrhage on a bird carcass is an accumulation of blood in the skin of a bird carcass, poured out from the capillaries, in the form of points or specks not exceeding 3 mm in diameter.

Bruising on a bird carcass is a subcutaneous or intramuscular accumulation of blood on a bird carcass as a result of traumatic injury.

Abrasions on a poultry carcass are damage caused by mechanical damage to the upper layers of the skin of a poultry carcass.

Scratches on a bird carcass are a defect in the form of a narrow strip, characterized by mechanical damage to the deeper layers of the skin of the bird carcass.

A skin rupture on a poultry carcass is a defect in the form of a narrow strip, characterized by mechanical damage to all layers of skin without damage to muscle tissue.

Over-scalding of a poultry carcass is a defect characterized by desquamation of the epidermis of the skin of the carcass without damaging the muscle tissue with a possible change in skin color.

Chill burn of a poultry carcass is a defect consisting in the appearance of characteristic light spots on the skin of a poultry carcass caused by local drying of the surface layer of the skin of a frozen poultry carcass.

Defects that occur when storage conditions and periods are violated are caused by various processes occurring during storage.

The smell of tanning, significant development of molds that have penetrated into the muscle tissue, a sharp change in the color of the surface of meat and fat, the presence of mucus, a strong smell of souring or a sharp musty smell.

A tan characterized by the odor of hydrogen sulfide, green skin color and copper-red muscle tissue. It occurs as a result of the activity of anaerobic bacteria or muscle tissue enzymes during slow cooling of fatty carcasses or their storage in an uncooled room.

Greening caused by the formation of sulfoaminoglobin and sulfomoglobin due to storage of fat carcasses at temperatures above +5°C.

Mold- plaque of white or black mold. This is the result of storing carcasses at temperatures above 10-12°C and with poor ventilation of the room.

Putrid smell in the oral cavity of carcasses, as well as in the abdominal cavity of gutted poultry. Appears at storage temperatures above 4-5°C as a result of the activity of putrefactive bacteria that destroy proteins.

Darkening carcass loss occurs in areas not covered with subcutaneous fat. The defect is caused by an increase in the concentration of dyes in muscle tissue and the transition of myoglobin to metmyoglobin during over-scalding and insufficient cooling before evisceration.

Red spots on the wings, neck, rump - this is the result of insufficient bleeding of the carcass. The meat of such carcasses acquires the tart taste characteristic of game.

Based on the results of the work done, the following conclusions can be drawn:

1 Poultry meat contains (in%): water - 50-70; proteins – 16-22; fat – 16-45; minerals and vitamins, extractives, small amounts of carbohydrates (glycogen). The nutritional value of poultry meat is characterized by the amount and ratio of proteins, fats, vitamins, minerals and the degree of their absorption by the human body; it is also determined by the energy content and taste properties of meat. The good digestibility of poultry meat (96%) is explained by its chemical composition. Land poultry meat is suitable for children's and dietary nutrition.

2 The morphological composition of poultry meat differs from the composition of slaughtered animals in that the bones of the poultry skeleton are thin and light, but very strong. The skeleton of a bird consists of the bones of the skull, spine, chest, pelvis, wings and legs.

3 The quality of poultry meat is formed under the influence of a number of factors: both intravital, characterized by the characteristics of the genotype, conditions of detention, and post-slaughter - processing technology, storage, etc. Post-slaughter changes in poultry meat (rigor mortis, ripening, deep autolysis) occur as in the meat of slaughtered animals, but are characterized by a higher intensity, which is associated with the peculiarities of the morphological and chemical composition of the bird. The ripening process improves the juiciness, tenderness, aroma and digestibility of meat. The entire process of post-mortem meat modification takes from 3 to 6 days, depending on the fatness: the more plump the carcass, the longer the rigor and ripening take.

4 Main species poultry are: chickens, geese, ducks, turkeys and guinea fowl. By type and age distinguish between young and adult poultry meat. By method of technological processing carcasses of all types of birds sent for sale are semi-gutted, gutted, gutted with a set of giblets and neck. According to thermal state Poultry carcasses can be cooled, chilled or frozen. The temperature in the thickness of the pectoral muscle of cooled carcasses should be no higher than 25°C; chilled – from 0 to 4ºС, frozen – no higher than -8°С. Depending on body condition and quality of post-mortem processing carcasses of all types of poultry (except old roosters) are divided into 2 categories - 1 and 2.

5 Requirements for packaging, transportation, conditions and shelf life of poultry carcass meat are set out in GOST 21784 - 76 “Poultry meat (carcasses of chickens, geese, turkeys, guinea fowl). Technical conditions". General requirements for the content of consumer information about poultry meat and its labeling are set out in paragraph 4.2; clause 4.3 GOST R 51074 – 2003 “Food products. Information for the consumer. General requirements".

6 Poultry meat, like many other groups of goods, is a product subject to mass falsification. Thus, the following types of falsification of poultry meat are found:

- assortment falsification– replacement of valuable meat with less valuable meat;

- high-quality falsification can be carried out in the following ways - replacing fresh meat with stale meat; replacing natural meat with abnormal meat; replacing part of the meat with water, blood; increasing the volume of meat with air; tinting with carrots and other dyes; bleaching meat with soda, introducing foreign additives. In addition, the group of high-quality falsifications includes the sale of meat from poisoned animals.

- Information falsification- deception of the consumer due to incomplete or distorted information about the product.

- Quantitative falsification(body kit) is a deception of the consumer by exceeding the possible deviation parameters of mass-determining equipment (scales) - one of the oldest methods of falsification.

7 Reception and sampling of poultry meat are carried out in accordance with GOST 28825 - 90 “Poultry meat. Acceptance." Selected poultry carcasses are assessed according to the following indicators: smell (if in doubt, the taste of meat and the aroma of the broth), fatness (the state of the muscular system and the presence of fat deposits), the degree of feathering, the condition and type of skin, the condition of the skeletal system, the shape, weight and temperature of the carcass. If there is a disagreement in assessing the quality of poultry meat, it is subject to chemical, microscopic, bacteriological and histological analyzes in accordance with GOST 7702.1. GOST 7702.1-74 provides for the determination of: indicators of ammonia and ammonium salts; peroxidase activity; amount of volatile fatty acids; acid and peroxide numbers of fat. In terms of weight and fatness, poultry carcasses must meet the requirements of GOST 21784 - 76. In terms of hygienic requirements for safety and nutritional value, poultry meat must meet the requirements of SanPiN 2.3.2.1078 - 01.

1 GOST R 51074 – 2003. “Food products. Information for the consumer. General requirements".

2 GOST 21784-76. “Poultry meat (carcasses of chickens, ducks, geese, turkeys, guinea fowl). Technical conditions".

3 GOST 28825 – 90. “Poultry meat. Acceptance."

4 GOST 7702.1-74. “Poultry meat. Methods of chemical and microscopic analysis of meat freshness."

5 GOST 16367 – 86. “Poultry processing industry. Terms and Definitions".

6 SanPiN 2.3.2.1078 – 01. “Hygienic requirements for the safety and nutritional value of food products.”

7 Instructions for veterinary branding of meat (approved by the Ministry of Agriculture of the Russian Federation 09/01/1992 N 19-7-2/139).

8 Kosnyreva L.M. Commodity research and examination of meat and meat products: A textbook for higher education students. textbook Establishments. - M.: Academy Publishing Center, 2005. – 320 p.