Do-it-yourself resistance spot welding. Contact welding. How resistance welding works

Resistance welding, in addition to the technological advantages of its application, has another important advantage - simple equipment for it can be made independently, and its operation does not require specific skills and initial experience.

1 Principles of resistance welding design and assembly

Contact welding, assembled with your own hands, can be used to solve quite wide range tasks of a non-serial and non-industrial nature for the repair and manufacture of products, mechanisms, equipment from various metals both at home and in small workshops.

Resistance welding ensures the creation of a welded joint between parts by heating the area of their contact with an electric current passing through them while simultaneously applying a compressive force to the joint area. Depending on the material (its thermal conductivity) and the geometric dimensions of the parts, as well as the power of the equipment used for welding them, the resistance welding process should proceed under the following parameters:

- low voltage in the power welding circuit – 1–10 V;

- in a short time - from 0.01 seconds to several;

- high welding pulse current - most often from 1000 A or higher;

- small melting zone;

- the compressive force applied to the welding site must be significant - tens to hundreds of kilograms.

Compliance with all these characteristics directly affects the quality of the resulting welded joint. You can only make devices for yourself, as in the video. The easiest way to assemble an alternating current welding machine with unregulated power. In it, the process of joining parts is controlled by changing the duration of the supplied electrical pulse. To do this, use a time relay or cope with this task manually “by eye” using a switch.

Homemade resistance spot welding is not very difficult to manufacture, and to perform its main unit - a welding transformer - you can pick up transformers from old microwave ovens, TVs, LATRs, inverters and the like. The windings of a suitable transformer will need to be rewound in accordance with the required voltage and welding current at its output.

The control circuit is selected ready-made or developed, and all other components, and, in particular, for the contact welding mechanism, are taken based on the power and parameters of the welding transformer. The contact welding mechanism is manufactured in accordance with the nature of the upcoming welding work according to any of the known schemes. Welding pliers are usually used.

All electrical connections must be made efficiently and have good contact. And connections using wires are made from conductors with a cross-section corresponding to the current flowing through them (as shown in the video). This is especially true for the power part - between the transformer and the electrodes of the clamps. At bad contacts the chains of the latter at the joints will experience large energy losses, sparking may occur, and welding may become impossible.

2 Diagram of a device for welding metal up to 1 mm thick

To connect parts using the contact method, you can assemble them according to the diagrams below. The proposed machine is designed for welding metals:

- sheets, the thickness of which is up to 1 mm;

- wires and rods with a diameter of up to 4 mm.

Basic specifications devices:

- supply voltage – alternating 50 Hz, 220 V;

- output voltage (on the electrodes of the contact welding mechanism - on the pliers) - alternating 4–7 V (idle);

- welding current (maximum pulse) – up to 1500 A.

Figure 1 shows a schematic electrical diagram of the entire device. The proposed resistance welding consists of a power part, a control circuit and an automatic switch AB1, which serves to turn on the power of the device and protect it in case of emergency situations. The first unit includes a welding transformer T2 and a contactless thyristor single-phase starter of the MTT4K type, which connects the primary winding T2 to the supply network.

Figure 2 shows a diagram of the windings of a welding transformer indicating the number of turns. The primary winding has 6 terminals, by switching which you can make stepwise rough adjustment of the output welding current of the secondary winding. In this case, pin No. 1 remains permanently connected to the network circuit, and the remaining 5 are used for adjustment, and only one of them is connected to power for operation.

Diagram of the MTT4K starter, produced in series, in Fig. 3. This module is a thyristor switch, which, when its contacts 5 and 4 are closed, switches the load through contacts 1 and 3, connected to the open circuit of the primary winding Tr2. MTT4K is designed for loads with a maximum voltage of up to 800 V and a current of up to 80 A. Such modules are produced in Zaporozhye at Element-Converter LLC.

The control circuit consists of:

- power supply;

- control circuits directly;

- relay K1.

The power supply can use any transformer with a power of no more than 20 W, designed to operate from a 220 V network and delivering a voltage of 20–25 V on the secondary winding. It is proposed to install a diode bridge of the KTs402 type as a rectifier, but any other with similar parameters or assembled from individual diodes.

Relay K1 serves to close contacts 4 and 5 of the MTT4K key. This occurs when voltage is applied from the control circuit to the winding of its coil. Since the switched current flowing through closed contacts 4 and 5 of the thyristor switch does not exceed 100 mA, almost any low-current electromagnetic relay with an operating voltage in the range of 15–20 V, for example, RES55, RES43, RES32 and the like, is suitable as K1.

3 Control circuit - what does it consist of and how does it work?

The control circuit performs the functions of a time relay. By turning on K1 for a given period of time, it sets the duration of exposure of the electrical pulse to the parts being welded. The control circuit consists of capacitors C1–C6, which must be electrolytic with a charging voltage of 50 V or higher, switches of the P2K type that have independent fixation, a button KH1 and two resistors - R1 and R2.

The capacitor capacity can be: 47 μF for C1 and C2, 100 μF for C3 and C4, 470 μF for C5 and C6. KN1 should have one normally closed and the other normally open contact. When AB1 is turned on, the capacitors connected via P2K to the control circuit and power supply (in Fig. 1, this is only C1) begin to charge. R1 limits the initial charging current, which can significantly increase the service life of the capacitors. Charging occurs through the normally closed contact group of the KN1 button, which was switched at that time.

When you press KN1, the normally closed contact group opens, disconnecting the control circuit from the power supply, and the normally open contact group closes, connecting the charged containers to relay K1. The capacitors are discharged, and the discharge current triggers K1.

The open normally closed contact group KH1 prevents the relay from being powered directly from the power supply. The greater the total capacity of the discharged capacitors, the longer they take to discharge, and, accordingly, K1 takes longer to close contacts 4 and 5 of the MTT4K switch, and the longer the welding pulse. When the capacitors are completely discharged, K1 will turn off and resistance welding will stop working. To prepare it for the next impulse, KH1 must be released. The capacitors are discharged through resistor R2, which should be variable and serves to more accurately regulate the duration of the welding pulse.

4 Power section - transformer

The proposed resistance welding can be assembled, as shown in the video, on the basis of a welding transformer made using a magnetic core from a 2.5 A transformer. These are found in LATRs, laboratory instruments and a number of other devices. The old winding must be removed. At the ends of the magnetic circuit it is necessary to install rings made of thin electrical cardboard.

They are folded along the inner and outer edges. Then the magnetic circuit must be wound over the rings with 3 or big amount layers of varnished fabric. Wires are used to make windings:

- For a primary 1.5 mm in diameter, it is better in fabric insulation - this will facilitate good impregnation of the winding with varnish;

- For a secondary with a diameter of 20 mm, multi-core in silicone insulation with a cross-sectional area of at least 300 mm 2.

The number of turns is indicated in Fig. 2. Intermediate conclusions are drawn from the primary winding. After winding, it is impregnated with varnish EP370, KS521 or similar. A cotton tape (1 layer) is wound over the primary coil, which is also impregnated with varnish. Then the secondary winding is laid and impregnated with varnish again.

5 How to make pliers?

Resistance welding can be equipped with pliers, which are mounted directly into the device body itself, as in the video, or with remote ones in the form of scissors. The first ones, from the point of view of making high-quality, reliable insulation between their nodes and ensuring good contact in the circuit from the transformer to the electrodes, are much easier to manufacture and connect than remote ones.

However, the clamping force developed by such a design, if the length of the movable arm of the pliers after the electrode is not increased, will be equal to the force created directly by the welder. Remote pliers are more convenient to use - you can work at some distance from the device. And the force they develop will depend on the length of the handles. However, it will be necessary to make fairly good insulation from textolite bushings and washers at the place of their movable bolted connection.

When making pliers, you need to foresee in advance the necessary extension of their electrodes - the distance from the body of the device or the place of the movable connection of the handles to the electrodes. The maximum possible distance from the edge of the sheet part to the place where the welding is performed will depend on this parameter.

The clamp electrodes are made from copper or beryllium bronze rods. You can use the tips of powerful soldering irons. In any case, the diameter of the electrodes must be no less than that of the wires supplying current to them. To obtain welding cores of the required quality, the size of the contact pads (tips of the electrodes) should be as small as possible.

Homemade resistance welding allows you to solve many problems in connecting various metal parts. Currently, extensive experience has been accumulated in the design and manufacture of welding machines at home. They are based on the use of common parts.

A do-it-yourself resistance welding machine can handle minor repairs.

Welding metals for domestic purposes usually does not provide for high productivity of the process and connection of large-sized products. This makes it much easier to make the devices yourself. A homemade device will not satisfy the requirements for industrial use, but homemade ones are simple and affordable for home use.

General principles and provisions

Any resistance welding is based on the joining of molten metals under a compressive load. Melting of metals is achieved by briefly passing an electric current through the contact area of two workpieces. An electric arc occurs in the metal contact zone, which determines the size of the welding area. The power of such an arc depends on the magnitude of the applied current, the time of its exposure and the compressive force, which largely determines the length of the arc. The size of the area affected by the arc depends on the size of the electrodes.

There are three main types of homemade resistance welding: spot, seam and butt. Spot resistance welding is most widespread. This type of welding ensures minimum size welding zones through the use of appropriate electrodes. Butt welding is based on the contact of the ends of the parts, while they themselves serve as electrodes.

Return to contents

Welding machine design

Homemade welding is carried out using spot or butt welding machines assembled with your own hands. Exist general rules designing such devices. Depending on the type of use, they can be portable or stationary. For welding machines, the main parameters are set: current strength, duration of the welding pulse, type and size of the electrode. The devices must be easy to manufacture and operate.

The resistance welding machine consists of two main blocks: a welding current source and a contact block. The welding current source must ensure that a welding pulse - a current of sufficient strength - enters the welding zone for a short time. The contact block contains the welded zone itself. Consequently, in this zone, contact between metals must be ensured and recorded, an electrical impulse must be applied to them through electrodes, and a compressive load must be created on the area of contact between the metals.

Return to contents

Figure 1. Transformer diagram for a welding machine.

Homemade resistance welding usually uses an electrical circuit based on capacitors. The welding current pulse in such sources is provided when the capacitor is discharged. One of possible schemes is shown in Fig. 1.

The welding current pulse is formed in the secondary winding of transformer Tr3. The primary winding of the transformer is connected to capacitors C8-C9, which provide the required discharge. The capacitor discharge is controlled through thyristors T1 and T2. The capacitor is charged through an auxiliary circuit from the input transformer Current. The circuit provides for current rectification with diodes D6-D7.

Such a capacitor source works in the following order. When the main circuit is disconnected, capacitors C8-C9 are charged from the current transformer circuit. When starting the system, they are discharged onto the secondary winding of the output transformer Tr3, in the mode of controlling thyristors T1-T2. The pulse duration is controlled by the Ru1-Ru2, R34 and C10 circuit. When the circuit is turned off, the process repeats.

The types and nominal values of the circuit parts are shown in Fig. 1. Recommended transformer parameters Current (220/220 V): the primary winding and both secondary windings are made of PEV-2 wire with a diameter of 0.5 mm, the number of turns is 90.

Return to contents

Homemade output transformer

The output transformer sets the strength of the welding current and is a very important element in the design of the power source. To ensure the necessary welding parameters, it is advisable to make it yourself. First you need to select the transformer core. It can be used from any old power apparatus. The main thing is that the core is made of steel plates, and the total cross-section of one rack is about 65 sq.cm. The steel plates are tightly placed together and tightened with bolts with a diameter of 8 mm. To increase the strength on the side, it is advisable to strengthen the core with a U-shaped profile or angle.

The primary winding is wound with PEV or PETV wire with a diameter of 2.9 mm. The number of turns is 20. The core is wrapped with transformer or cable paper. Then the turns of wire are wound with tension. You should strive for a uniform arrangement of turns along the length of the core strut. The ends of the winding are brought out to the top of the core and secured in the terminal block. A paper wrap is placed over the wire and secured with tape.

The secondary winding is wound on the second core post. The winding is made from a homemade flat busbar assembled from 15-16 copper bars. The total cross-section of the tire is about 200 square meters. mm. The number of turns is 2. Before applying it to the core, the tire is wrapped with fluoroplastic tape or fabric insulating tape. Paper is placed under the winding and on top of the winding in the same way as the primary winding. The ends of the winding are brought out to the top of the core. A hole is made in them for bolting the cable, which extends to the contact block of the welding machine.

Such a transformer has the following characteristics: power 3000 W; primary winding voltage - 220 V, secondary - 15 V. Welding current - up to 200 A.

Return to contents

Assembling the current source

It is advisable to assemble the welding power source inside one cabinet. The approximate size of such a metal cabinet is 50x80x40 cm. It is better to strengthen its bottom with corners, and install an output transformer on them. The electrical circuit (plateau) is assembled on a textolite panel, which is fixed vertically to the side inside the cabinet. The cabinet is equipped with contact blocks for connecting the electrical network, as well as a bolt for grounding. All wiring inside the cabinet is collected in bundles and carefully laid along the wall. Holes are drilled in the rear wall for the electrical input and the outlet of the welding cable and cable (wire) to the start button.

Return to contents

Contact block design

Depending on the type of contact welding, several contact block designs can be recommended. Most simple design provided for butt welding. In this case, the ends of the secondary winding are connected directly to the workpieces being welded. One end of the transformer winding is connected to one workpiece, and the other end is connected to another workpiece.

Spot welding involves the use of a contact block with electrodes. Designs with one or two rod electrodes can be used. In the case of using a single electrode, the welding current is supplied to one of the workpieces, and the second end of the secondary winding of the output transformer is connected to the electrode.

Return to contents

Manufacturing of butt-type contact block

The contact block for butt welding contains a stationary fastening of one of the workpieces to be welded and a movable clamp for the second workpiece. The block is assembled on a base made of textolite with a thickness of at least 10 mm. The fixed clamp is made of two steel parts. The lower body is a rectangular block 100x50x30 mm. A 50x20 mm cutout is made in the upper part to install the lower die and two threaded holes are drilled for attaching the clamp cover. Two threaded holes are drilled at the lower end of the body for fastening to the base.

The clamp cover is made of steel strip with a thickness of at least 5 mm. The strip is given a U-shaped profile with bent ears for attachment to the clamp body. The U-shaped profile has dimensions equal to the dimensions of the cutout in the body and is intended for installing the top die. Holes are drilled on the ears. The dies are designed for clamping the workpiece to be welded and are made of steel bars measuring 50x20x30 mm. On the opposite faces of the dies, several (3-5 pieces) grooves are made parallel to each other according to the size of the intended workpiece. For fastening, the workpiece is installed between dies, which are inserted into the body and cover and clamped with screws.

The movable clamp is made similarly to the fixed clamp, but a longitudinal groove is made in the lower part of the body for installation in the guide rails. The runners themselves, in the form of a U-shaped profile, are attached to the base of the block. The clamp displacement itself is ensured by an adjusting screw with a diameter of 10-15 mm and a length of up to 10 cm. The clamp movement unit is made of a steel strip with a thickness of at least 5 mm. The strip bends at a right angle. Two threaded holes are drilled on the bottom for fastening to the base of the block. A threaded hole is drilled on the side surface to install the adjusting screw. This hole is drilled in the middle of the strip at a height of 20-25 mm from the base. The clamp moves along the guides due to the movement of the adjusting screw.

Quite often there is a need to carry out welding work at home. As a rule, these are small volumes performed occasionally. Since factory-made welding machines are very expensive, many craftsmen prefer to make them different ways from scrap materials. A good option for a factory analogue is considered to be do-it-yourself contact welding from an inverter, which ensures high quality work at a relatively low cost.

The device and principle of operation of resistance welding

The principle of operation of any spot welding machine is to heat metal parts with electric current in certain places, then melt them, mix them together and solidify. As a result, a weld seam is formed in the places where both metals solidify. During operation, both parts are reliably compressed and fixed by electrodes to which electric current is supplied.

Performing resistance welding at home will require powerful power sources, which can lead to overheating and failure of household electrical wiring. In this regard, it is recommended to check the condition of the wiring in advance and replace it if necessary.

When performing spot welding, two workpieces are joined together along adjacent edges. This method very effective for working with small parts, thin metal sheets and rods with a diameter of up to 5 mm.

Surfaces are connected in one of three ways:

- When using the reflow method, all parts to be welded are joined and heated by electric current until they melt. This technology is widely used in working with non-ferrous metals, low-carbon steels, brass and copper workpieces. In other areas this method is used extremely rarely due to high requirements To temperature conditions and the absence of impurities at the joints. Homemade resistance welding from a welding machine works in exactly the same way.

- Continuous welding of workpieces using the reflow method is performed using welding tongs. The connection of parts occurs at the moment the current is turned on. After the edges of the mounted parts have melted, they are upset and the current supply is stopped. Thin-walled pipelines and workpieces with different structures are welded using this method. The main disadvantage of this method is the likelihood of metal leaking out of the weld and the appearance of carbon monoxide.

- The third method is intermittent melting, which ensures alternately tight or loose contact between the workpieces. The welding line is closed in the joint area with clamping pliers until their temperature rises to 950 degrees. This method is used if the power of the welding device is initially insufficient to perform continuous reflow.

Preparing parts and assembling spot welding

The standard design of a resistance welding machine consists of a power section, a circuit breaker and a protective device. In turn, the power part includes a welding transformer and a thyristor starter, with the help of which the primary winding is connected. The entire inverter is not needed for a homemade welding machine; you only need to take the main parts from it. This is a transformer with a power supply, a control system and a switch.

When making spot welding, first of all, you need to remove the secondary winding from the transformer, since it is not used at all during operation. The main thing when removing the winding is to keep the primary winding intact. Instead of the removed secondary winding, another one is placed, made of thick copper wire, with a cross-section of approximately 2-3 cm. Then it is wrapped in insulating paper and varnished for additional insulation and fixation.

The direction of each winding is then checked using a conventional voltmeter. The newly created chain should not contain short circuits. After this, the current strength is determined. This procedure is mandatory for all such devices with two or more windings. The current value should not be more than 2 kiloamperes. If the set level is exceeded, it must be reduced.

When preparing the transformer coil and winding the secondary winding, it is recommended to follow the mandatory rules. To calculate the number of turns, you can use the formula N = 50/S, in which N is the number of turns, and S is the core area (cm2). Helps speed up calculations online calculator calculating the inductor. Since the design uses parts from the inverter, the parameters of the primary coil are first determined, the necessary calculations are made, and only then the secondary winding can be manufactured.

Pay attention to the grounding of both windings. This is due to the high power of the current received, which can be fatal if it comes into contact with live parts. Along with careful insulation, tight laying of the turns is of great importance. Otherwise, interturn short circuits may occur and the wires will burn out as a result of overheating. It is also necessary to take care of cooling the transformer. It may be necessary to install an additional cooling system, which includes radiators blown by fans.

Additional elements of the welding machine

The next step after manufacturing the transformer will be the manufacture of contact clamps. The quality of their manufacture largely determines how resistance welding from an inverter will work. The design of the pliers is selected depending on the specifics of future welding work. The gripping device is manufactured in accordance with the drive system and the dimensions of the parts to be connected.

The most important part of the pliers is considered contact tips. You can use copper tips from a soldering iron or purchase ready-made products. It should also be taken into account that they should not melt during operation, so a refractory metal should be used for their manufacture. Typically rods with a diameter of about 15 mm are used. The diameter of the connected cable is always less than the diameter of the lugs.

The wires are connected to the electrodes using ordinary copper lugs. Direct connection is carried out by bolts or soldering, which significantly reduces the likelihood of oxidation at the contact points. Soldering is most often used in low-power devices, eliminating incorrect connections that cause current disturbances at the output of the device.

The main advantage of bolted connections is the ability to quickly replace failed parts without additional soldering work. All bolts and nuts must be copper. If it is intended to apply connecting seams over a long distance, in this case the tips are equipped with special rollers.

After manufacturing the pliers, the time comes to solve an equally difficult task - ensuring the necessary pressure of the electrodes at the point of welding the parts. The main difficulty lies in the fact that it is impossible to create high and uniform pressure manually. If other options are not considered, then it is best to initially refuse to make spot welding from an inverter, because the efficiency of such a device will be extremely low.

In industry, this problem is successfully solved by using amplifiers based on pneumatic or hydraulic systems. It is almost impossible to make such devices at home. For homemade spot welding, the best option is a compressed air system driven by a conventional pneumatic compressor. The most optimal maximum indicator required for normal operation will be a force at the ends of the electrodes of 100 kg or more. Pressure changes using a separate regulator, which can be built into common system management.

At the final stage of assembling resistance welding from the inverter, all that remains is to mount the entire system. For installation, it is recommended to use ready-made elements, which greatly simplifies assembly and improves performance characteristics. All the missing parts are in the inverter, from which the transformer was already taken.

The capacity of the capacitors installed in the inverter may not be sufficient for normal operation. Therefore, if necessary, they are replaced with other parts that are most suitable in their parameters. Next, stepwise current adjustment is performed, the accuracy of which is affected by the technical characteristics of the secondary winding. By making such adjustments, it is possible to create equipment capable of operating in different modes.

Welding capabilities in body repair

The need for welding work during body repair is beyond doubt. And so that this process does not take time, and also allows you to fix many problems yourself, it is important to select the appropriate equipment.

Body repair is unthinkable without resistance welding

Welding process during body repair

The vast majority of work when repairing a car body can be performed by resistance welding. This type, being quite specific, is used mainly due to its simplicity, lack of Supplies And high level productivity.

More about resistance welding

According to technical definition This type of welding work is a process during which a permanent connection is formed. Such a connection is a consequence of heating the metal through a passing electric current, as well as plastic deformation of the connection zone itself (the latter occurs as a result of compression).

There are several ways to do resistance welding yourself, including spot welding. This scheme involves connecting parts in separate sections, which are called points.

To obtain a welded point, the parts to be welded (preliminarily thoroughly cleaned) are overlapped, compressed with a certain force, after which a current pulse is passed through the place of their contact. At the contact boundary of the parts being welded, the machine forms a melt point called the core of the point. When the flow of current is completed, this core will crystallize and form a very strong connection.

Drilling before joining parts

There are a number of factors that can influence quality, i.e. point strength and size:

- We are talking about such a parameter as compression force;

- The value of the welding current that the machine produces also plays a certain role;

- The duration of the current pulse is also important;

- Finally, the diameter of the contact surface of the electrodes matters.

Appliances used

Do-it-yourself contact welding during body work is carried out using appropriate welding machines. The scheme of their use assumes the following: the machine (device in other words) heats up, and as a result of heat generation, direct welding occurs in those places where the parts are connected.

It turns out that any device is based on the principle of heating the welding site with current while simultaneously applying pressure.

A stationary machine can be used, as well as a suspended or mobile machine (for self made). Each such device, in turn, is divided into certain varieties, taking into account the welding method.

The design of each device assumes the presence of a number of parts: electrical, mechanical, hydraulic system, pneumatic system (or water cooling system).

A resistance welding machine can easily be constructed with your own hands, which is what we propose to talk about in more detail.

Factory seam sample

Self-assembly of the device

The resistance welding apparatus consists of two units:

- Remote welding gun;

- Power unit.

The manual assembly procedure is well demonstrated in numerous videos. The process of making a gun begins with the creation of an adapter and electrodes. To do this, take a textolite sheet and cut out linings from it (the dimensions are determined by own hand). Then you need to drill channels in the lamp holder for the wires. These wires will lead to the backlight.

The microswitch is attached to the finished overlays using screws and two holders. Spacer strips can be bent from a strip of plexiglass, taking into account their location on the overlays. We should not forget about the placement of the welding cable passing through the handle.

The end of such a cable is soldered, then inserted into the adapter hole and secured with a screw. It is recommended to dull the sharp edges of the linings. It is important to wrap the handle with insulating tape. The finished version, again, is perfectly seen in the video.

As for the power supply, it is assembled from a relay on a welding transformer and a thyristor. The electrode is connected to one terminal of the low-voltage winding using a welding cable. Second output during manual welding must be reliably connected to the most massive part to be welded.

The primary winding of the transformer is connected to the network via a diode bridge and a thyristor included in its diagonal. In this case, an auxiliary transformer is also needed to control the thyristors and the backlight.

That is, homemade resistance welding is quite possible. After assembly is completed, the welding machine must be tested. The finished device (the video shows what it looks like) will allow you to perform many jobs.

Thus, when assembling the corresponding resistance welding machine with your own hands, you need to stock up on the above elements for the gun, as well as for the transformer. Since it is the transformer that influences the final size of the device, it is recommended to start the assembly process with it.

How to do spot welding with your own hands and what you need to know

Preface

Do-it-yourself spot welding can be done in just a few hours. This is not a high-tech mechanism that should only be assembled at the factory, and you will soon see this! Now we will assemble a device whose technical characteristics will not be inferior to those of the purchased product!

Assembling the transformer

The most important part, the heart of any electrical device of this type, is the transformer, with the help of which we will receive the necessary voltage. The transformation coefficient must be very high, so we immediately turn our attention to powerful and voluminous microwave ovens - this is where you can get the necessary element. The power should be about 1 kW - this is an ideal option, but if this is not available, 700-800 W will do. In a microwave oven, a step-up transformer produces up to 4 kW to power the magnetron. Exactly what we need. We are considering step by step instructions for the manufacture of the necessary transformer.

Step 1: Remove the transformer from the microwave.

You shouldn’t immediately disassemble it with a hammer - we will need it entirely. We unscrew the base, remove all the fasteners, and take it out.

Step 2 We knock down the secondary winding.

We only need the primary one (this is the one inside, the wire on it is much thicker and there is less of it). You can do this with a chisel, hammer, hacksaw, even drill out the corners with an electric drill - anything, as long as the result is what you need. Your task: do not damage the primary winding and magnetic circuit, and you can do with everything else as you wish, even for scrap metal.

Step 3 We wind the secondary winding.

We need to get a current of about 1000 A as a result, so we go to the market and buy a wire with a diameter of 1 cm. It is expensive, but we cannot do without it. If you want to save money, buy it in a bunch, and not one whole piece - this does not affect the progress of the matter.

Step 4 Make 2-3 turns.

We make 2-3 turns of the secondary winding, at the output we get about 2V. The more you put into the window, the greater the voltage will be, although after 3 turns there is no room left in the window. If you need a powerful device, then you can disassemble 1 more microwave or find an additional transformer and connect 2 together. It will be possible to work with metal up to 5 mm thick.

Step 5 Check the direction of the windings.

Using a voltmeter, we check the direction of the windings, as well as the presence of short circuits. If none can be traced, you can move on to further work.

Step 6Check the current strength.

When connecting 2 or more transformer windings, it is necessary to check the current strength at the output. If it is more than 2000 A, reduce it. This will lead to drops in network voltage and you simply won’t be able to fend off your neighbors who will run around complaining about you.

Making electrodes

Everything here is simpler than steamed turnips. We buy electrodes from scrap metal or the market; copper rods with a diameter of 1.5 cm or more are suitable for this. The main thing to remember is that the diameter of the electrode should not be less than the diameter of the wire and that’s it. If your welding is weak, then you can destroy 2 soldering irons and take the tips from them - ideal and durable electrodes that will last a long time!

The wire that connects to the electrode must be of a minimum length to reduce current loss. For the connection, a copper tip or hole is used, which can be made with an electric drill and an 8-mm drill bit. Tighten the bolted connection and the rod will not run away anywhere. You can solder the tip to the wire to avoid oxidation that will occur when you first start the device. Unsoldered contacts can create additional resistance, which is very noticeable at low power of the device.

The only advantage of bolted connections is that the electrodes can be removed quickly, otherwise they will have to be completely re-soldered. This is often done during intensive use, so it makes sense to fasten it this way. It’s easier to buy copper bolts and nuts - the result will be much better. Homemade resistance welding will be “fun”; you can remove the electrode in a minute, instead of soldering them for half a day.

Process control and "infrastructure"

This includes the lever and switches. You simply cannot do without good compression force, especially when welding thick sheets of metal. That is why you need to take care of high-quality leverage. On a production scale, the force can reach 50-100 and even 1000 kg, but 30 kg will be enough for us, so we make the lever moderately long so that doing resistance welding with your own hands is convenient.

It is best to pull the beginning of the lever arm out from the table so that the emphasis is on it and not on the machine (suitable for stationary welding devices). The length of the handle should be about 60 centimeters with a fastening ¾ from the bottom, so that the arm on the clamp is equal to at least 1:10. Then, when applying 2 kg on the handle, you will be pushing up to 20 kg on the metal leaning against the work surface.

As for the switch, everything is simple: we put it on the primary winding, since there will be a very large current on the secondary winding, the resistance of the switch will interfere with the operation of the device. You can place the lever on the handle - original and very practical. You will be able to turn on the device only after metal contact, which will reduce energy costs and protect against sparks.

Homemade spot welding is already ready and now it’s enough just to test it in operation to check the correctness of the assembly. It is suitable for welding metal up to 2-3 millimeters thick when using a 1 kW transformer and up to 5 mm when connecting two or more in series!

Due to the fact that welding contact for a time that is much less than fusion by fusion, it provides greater productivity and less flexibility of operation, since

Contact welding. Types of resistance welding.

Since the process is easy to automate and easier to integrate with flow conveyors, this method is better used for mass production and mass production.

This method has been used in the automotive and aerospace industries.

Since joints obtained by resistance welding have very high strength and quality, and do not depend on the quality of welding, this method is used in other industries.

With the thickness of the weld seam, connect from hundreds to tens of millimeters, as well as tens of mm.

Also welding of oil and gas pipelines.

For robots, systems with an increased supply voltage frequency are used, which makes it possible to reduce the size of the transformer.

Classification of welding methods

In accordance with GOST 158-78-77 “Resistance welded and welded joints” there are 3 main types:

— spot welding;

— seam welding;

— Direct welding.

However, the series of these methods reaches 300 names.

Spot welding(Kt) - a method in which parts are welded at separate points with two electrodes and a welding pressure is applied to them, transferring the welding current.

pulse welding time

Relieve the pressure, cool the part and get a casting of the core.

The design of a welded joint (a shaped core of a certain size) is determined by two important physical phenomena:

1. Welding metals with welding current

Q = J^2cRtu

second

Heat transfer from the welding zone λ-thermal conductivity

Sv In the range of electrodes, heat is released during the passage of current and heat, transferred to the mass of work and the action of the electrode.

because

E. Thomson decided to use a copper electrode and λcu >> If the shape of the cast core is lens-shaped, it is favorable for the welded joint.

If Jcb and Tcc are increased, a molten core begins to develop.

The use of cast electrodes and the increased heat transfer in them compared to the mass of work determine the development of the melting process in the casting core precisely in the mass of work, and not in the electrode.

In this regard, the probability of failure is reduced by melting at the core, i.e.

Burns are complex, which determines the effectiveness of spot welding.

Relief Welding - This may be associated with one of the types of site welding.

A spot weld joint is created by local heating of the work with electric current and plastic deformation in the joint area due to compressive force.

Q (R) - due to increased stability;

— Q (λ) — metals actively redirect heat.

The connection is created due to two effects:

QI^2R

—Qλ

Protective welding contact(Cylinder)

Rm - The seam seal overlaps the welded parts in the flow line of the cylinders (electrodes), pushing the parts from the side that feed the JSV flow and the moving parts at the VSV welding speed - even through those rollers.

It is used in cases where welded joints must be sealed with welding contacts.

Sealed Sewing - For welding containers, gas cylinders, tanks, cavities, etc.

J = I / S - current density

Jš - current

The process is carried out by removing heat and heat.

Seam welding is divided into three processes:

- continuously

With this method, where the thread is constantly continuous, a continuous weld is obtained without the distinctive casting of the core that overlaps.

The disadvantage is the increased heating of the electrode and the need for frequent flow.

— Individual impulses (interruption)

— Q = f (λ) (tcb + tn)

Changing the amplitude of the current JSV, the duration of its generation - Jc, the duration of the rupture - tn and the welding speed - USV can regulate the amount of overlap LN of cast cores, which is usually sufficient up to 25%, but should not be performed ln>50%.

Thanks to the better impact of the electrode, their resistance is significantly improved.

When welding heat-resistant steels with low thermal conductivity and high resistance to deformation at high t (thermal resistance), the welding forces increase, i.e.

welding stage.

Step welding— the welding current is interrupted, the electrodes stop when the welding current passes.

It provides more reliable contact in the current range when the electrodes stop and the welding pulse passes.

After turning off the current, welding forces in the contact area avoid hot cracks.

Contact - welding

There are several types of welding contacts (Ks).

Consider the method weld resistance, while the parts are first pressed against the electrodes using jaws (prismatic electrodes) to ensure electrical contact and not slip through the electrodes.

It is then compressed by the welding force P, the welding current is turned on, and the parts in the joint are heated by this current Ic.

Then place the rosette 1.5-2 times less than the heating, then turn on the current, and the parts are exposed to P precipitation.

At the moment when the smallest deformable resistor is used, the sediment force is applied and the current is switched off, and the metal layers, heated to high ductility, are compressed from the intersection to the periphery.

At the same time, residual oxide films and honeycomb (metal on the edge of the bonding zone) are removed from the joint.

Thus, small parts with a diameter of up to 20-40 mm are welded, and the connection is formed in the solid phase without melting the metal. The heated plastic metal is forced into the hail, and the solid heated particles of the working material come into contact.

The disadvantage is the need for careful preparation of the weld ends and the need to connect large capacities to the large plant capacity.

Another way - flash welding.

It is technologically different from resistance welding, so the voltage in the primary winding of the transformer (and in the secondary) is guaranteed until the ends of the breakers touch.

As the parts approach contact, individual microscopes enter the contact surface in much fewer numbers than if the parts had been pressed in advance.

The keels are destroyed and the contact surface increases. At the first contact, the welding current arises and occurs on several microspheres, so the current density in the contact of an individual microspace is so high that the metal heats up in milliseconds and then boils. In this case, explosive destruction of the liquid contact bridges occurs.

New microstate contacts are in contact with metal vapor, i.e.

The increased metal vapor pressure in the joint protects the welding area, which heats up to TPL when interacting with the atmosphere.

When melting, the ends work in such a state that a thin layer of liquid metal appears on the surface, which ensures uniform heating over the entire area of the joint; the force of the sediment is applied to it. The liquid layer from the ends is compressed to the edge of the joint - in hail and under high pressure the compressed parts of the part come into contact,

TV. I'm next to the liquid layer not much lower than tpl, and was very plastic, and then partially and hard metal compresses into hail, and under pressure a strong welded joint with the least amount of errors. degradation products and oxide films were extruded into hail.

Fused welding provides a better connection because the metal on the surface of the ends where contamination can occur is removed when the liquid bridges explode during the reflux process.

The liquid layer and part of the ductile metal are compressed into a hail, and completely clean (young) surfaces come into contact.

This does not require careful processing of the weld ends, as is the case with resistance welding.

In addition, if welding parts with different cross-sections form a special edge section, the initial contact surface is reduced, the fusion process is more efficient and the process continues, the parts are heated and have a normal shape.

Shield welding with intermediate payment or preheating

When front welding large parts: rails, pipes, main pipelines - to facilitate the initial phase of the reflow process, the process used includes the first stocks to slowly reduce the occurrence of contact and the formation of liquid and metal vapor.

The parts are then heated, and the heat generated in the fusion zone spreads to the work mass and is heated.

The contact between the switches is then recreated until the ends are heated, so that the further process is continuous, without interruption.

Turn to lightweight welding(WITH)

This may be due to the types of spot welding.

It is used for welding parts that occupy a large spatial position.

Usually the Scheme 1 process does not work because the contact with all parts of our work cannot be the same due to the difference in device quality, deformation conditions, contact location from the current guide device.

This fusion welding process occurs by forming a solid-phase joint by extruding a liquid phase to the periphery.

To ensure the same conditions for contacting and deforming a large number of parts are necessary to ensure reliable contact with each electrode and parts in the first welding force (or previous pressing force) that compresses all the rods.

This should provide slight deformation of the parts in contact.

The forces are then removed to the welding force value. Because the same conditions for contact with all parts are not guaranteed, but it is better to first provide a heat pump pulse in which the parts are heated in contact and by the welding force.

Then you can still JOP, then turn on the welding current.

Forging force is used to reduce the base and we obtain a multi-point connection with high quality.

At the starting point, the current flows along the points, the area is small and the current is high, they begin to melt and then become deformed during welding.

We kill cores and small tracks without any supports or fins.

When welding once, several welded joints are obtained. However, if the parts have a protective coating that must remain on the surface after welding, only weld welding should be used, since the large surface area between the electrode and the part has a low current density and the coating will remain.

Physicochemical conditions for the formation of compounds

Weld design in resistance welding.

Welding metals with welding current

Heating and melting of metals at the point of contact, releasing energy when passing through an electric current. Spot welding current

Replacement of current in resistance welding at several points.

Contact zone welding and seam welding

Factors influencing the design of a quality weld.

Welding on the floor

Spot contacts in resistance welding. Seam welding

Merge in a seam of successive dots.

Relief welding

Welding with contact in prepared relief. Control circuits for switching welding devices

Electrical circuits to provide welding current and voltage on contact machines. Contactor machine contactors

On and off devices. Welding or secondary circuit of contact machines

Current-carrying elements for high currents and compressive forces.

Transformers for resistance welding machines

Characteristics of transformers for resistance welding. Pneumatic equipment for contact machines

Pressure relief devices.

Also on topic:

Special methods

Resistance welding modes are a set of parameters that are set by the welder before starting work. The parameters of these welding modes depend on the metal product that is planned to be welded, the experience of the welder, and other things. The selected welding modes directly affect the quality of the resulting joint: incorrectly selected parameters can lead to a poor-quality weld, which may subsequently crack.

The main parameters for resistance welding will be:

- Electric current strength.

- Increased compression for welded parts.

- Duration of current flow.

We will talk about different welding modes, and specifically the contact welding method, further.

Welding modes and their influence on the weldability of metals.

Welding modes are divided into two main types:

Both types differ in the duration of current exposure to the part being welded.

The hard mode of welding a metal product involves a short-term exposure to current on the parts, while soft welding modes, on the contrary, involve a long-term exposure.

The choice of one type or another depends, first of all, on the metal that needs to be welded: its thickness, thermal conductivity, etc. matter.

Thus, severe welding modes are usually used for metals that have greater thickness, but at the same time lower thermal conductivity. For example, the welding conditions for low-carbon steel will be much tougher than for aluminum alloys

The form of metal melting and the location of the melt zone largely depends on the processes of heat release and heat removal that occur in the electrode and the part being welded.

The duration of exposure to current affects heat generation and heat removal, and, accordingly, the welded joint itself.

When welding is carried out in a soft mode, the shape and location of the cast zone will depend directly on the electrode and the materials being welded. Thus, in the soft welding mode, the cast core is at the same distance from the surfaces of the part, this contributes to the fact that the irregularities formed during the welding process are shifted into a part that has a greater thickness.

Note that under soft welding conditions (in which the heating time of the metal product is much longer), the heat-affected zone will also be wider than during hard welding.

During rigid welding, this core will be located quite symmetrically in relation to both parts being welded.

During welding, it is necessary to take into account that the heat dissipation into the electrodes during hard welding is minimal, this is what makes it possible to obtain a greater height of the cast zone in this welding mode (in other words, hard welding modes of parts having the same thickness give a greater depth of penetration).

The quality of the resulting welded joints made under different welding modes is assessed according to the following parameters:

- The seam should not have significant softening in the metal joining area.

- The formation of rather fragile structures in the joint zone, which may subsequently collapse, is unacceptable.

This especially applies to the transition zone of the seam.

- The joint area must be uniform and tight, the cast and transition zones must not have any visible disruption of their complexity.

- The connection must be strong enough.

- Welding work should not reduce the corrosion resistance of the metal product.

- Deformations of parts are allowed within normal limits.

Note that when performing resistance welding, compliance with these conditions depends on the capabilities of your welding equipment, the product itself that will be welded, and the experience of the welder.

Keep in mind that metals that have good weldability allow welders to use a variety of parameters to set the weld, which in turn results in better joints.

Contact welding methods and joint formation.

All methods and modes of resistance welding are based on heating parts using heat, which is released when an electric current flows through them.

The amount of heat released mainly depends on the strength of the current, the time it flows through the metal, and also on the resistance of the metal itself in the welding zone.

If two or more parts compressed together are welded, then electric current is supplied to them through conventional electrodes.

Spot welding device

In this case, the voltage can be small, from 3 V, but the current can reach tens of thousands of amperes. The heat that is necessary for welding is released mainly in the parts, in the area of contact of the parts with each other and their contact with the electrodes. In this case, in contact welding modes, it is essential electrical resistance metals

Thus, we conclude that the choice of welding mode depends directly on the properties of the selected materials.

Resistance welding modes depend on the thermal conductivity and thickness of the parts.

Note that in harsh modes the amount of heat released is many times greater, so they are used only for metals with low thermal conductivity, for example steel.

According to physical characteristics, contact welding belongs to the thermomechanical class. This means that it is carried out using thermal energy and pressure. Heat is released from special sources when an electric current passes at the point of contact of the parts being connected. The metal is heated to a plastic state and at the same time it is joined under significant compression.

This type of welding is used to join ferrous, non-ferrous and dissimilar metals.

3. Resistance welding methods

Depending on the contact welding method, metal up to 20 mm thick can be welded. Resistance welding is used in many areas of industry - aircraft, aviation, shipbuilding, mechanical engineering, in the energy industry, agriculture, construction.

Resistance welding methods

The main welding methods are:

- point;

- suture;

- butt.

Spot welding is used to overlap parts made of profile, sheet and strip metal.

Parts made of both homogeneous and dissimilar metals, as well as having different thicknesses, are connected. Depending on the equipment used, welding can be carried out at one point or at several points simultaneously.

The spot welding process consists of the following steps:

- cleaning parts;

- alignment and placement of parts between the electrodes of the welding machine;

- heating to a state of plasticity;

- compressing the electrodes with the necessary force.

Cleaning of parts is carried out immediately before welding by mechanical or chemical means.

Rust, oxides and other contaminants are removed.

To combine parts, special devices called jigs are used.

Heating of parts at the welding site is carried out by applying a short-term pulse (0.1 ÷ 3 seconds), which ensures melting of the metal.

The current power can reach 100,000A, and the voltage can reach 10 V. A liquid core is formed. After the pulse is removed, the parts are compressed to form a point (crystallization and cooling occurs). The core diameter, depending on the equipment used and welding technology, ranges from 4 to 12 mm.

Spot welding can occur in 2 modes:

They differ in the density of welding and the passage time of the electric current.

In the soft mode, heating is carried out gradually (0.5 ÷ 3 sec.) with a moderate current intensity (does not exceed 100 A/mm2), and in the hard mode, the welding time usually occurs in the range of 0.01 - 1.5 sec., and the current density is 120 ÷ 300 A/sec. The compressive force of the electrodes ranges from 3 to 8 kN/mm2.

In seam welding, or also called roller welding, the parts are also connected by points that may or may not overlap each other.

The welding process takes place on special machines with disc rollers-electrodes. During the welding process, they rotate, while tightly compressing the parts being welded. The equipment may have one or two electrode rollers. This type of welding is used to make containers for various purposes (barrels, pipes, gas tanks, etc.), where the products are subject to tightness requirements.

Seam welding can be performed in 3 ways:

- stepping;

- intermittent;

- continuous.

Step welding is used to weld clad metals, aluminum and its alloys up to 3 mm thick.

The parts are welded at a certain pitch, and a large welding current is switched on when the rollers stop.

Intermittent seam welding is performed to join metals up to 3 mm thick under the following conditions:

- continuous feed parts into the welding zone;

- short-term interruption of the current as it passes through the workpieces.

During the welding process, points overlap as a result of the correct selection of the rotation speed of the electrode rollers and the pulse frequency of the welding current.

Thanks to this welding method, the parts and rollers do not overheat, which allows you to obtain a high-quality sealed seam.

Continuous seam welding differs from intermittent welding only in that with the continuous supply of parts to the welding zone, a continuous flow of current occurs. This type of welding is used for parts made of low-carbon steels up to 1 mm thick, and also parts of non-critical structures are made using this method.

The quality of the weld is low, because During the welding process, overheating of the welded parts and electrode rollers occurs.

For resistance seam welding, electrodes Ø 40 ÷ 200 mm made of pure copper (grade M1), bronze (cadmium, beryllium and other types) and their alloys are used.

Contact butt welding, depending on the method of its execution, is used for butt-joining parts made from the most various materials and their combinations, with an area of up to 1000 cm2.

In this way, rods of any shape (round, rectangular), profiles, rails, corners, wheel rims, etc. are welded. Designed for butt welding a large number of resistance welding machines and devices (spotters), differing in power and design.

The essence of welding is that parts, during the heating process, are connected along the entire plane of their contact.

Welding can be performed in 2 ways:

- reflow;

- resistance.

Reflow welding received wide application, because does not require preliminary preparation products for welding. It comes in two types - with preheating of parts before welding and without it (continuous fusion welding).

To carry out resistance butt welding, a wide range of the lineup machines that have special clamps in which parts are secured before welding.

The clamps are installed as follows - one on a fixed plate, and the second on a movable one. When the parts come together until they touch, a current is switched on, which melts the metal to a plastic state, then compression occurs under the influence of force, the magnitude of which depends on the thickness of the product and the metal.

This ensures a strong connection between the parts.

Flash welding with preheating is carried out for metals that can be hardened during the welding process. This heating promotes uniform heating of the metal and its slow cooling, which has a positive effect on welding.

Welding pliers

Welding tongs are suspended type devices.

Used in industry and small repair shops, as well as in service centers. The thickness of metal parts welded using such devices does not exceed 4 mm.

The pliers are connected to the welding transformer using flexible wires, which allows work to be carried out in the required place. And allows you to weld large-sized products.

Various manufacturers produce a wide range of welding guns.

Some of them allow you to remotely select welding programs, change the welding position during operation, auto-repeat welding, monitor the condition of the electrodes, and even issue a message about the need to replace the electrodes or the need to clean them.

Making resistance welding yourself

A country house always requires special care from the owner. There are many more of them than in the apartment. Repairing and rebuilding a house, constructing decorative bridges and gazebos, constructing foundations and ceilings, all this work requires the ability to work not only with wood, but also with metal. Appropriate tools and equipment are needed for such work.

Skill and experience, the ability to work and come up with interesting projects sometimes comes down to only one thing: not all the work can be done by the owner himself. And this very often stops interesting creative ideas.

As a rule, this happens when it comes to welding. It is believed that it is impossible to weld metal structures without a specialist with a special apparatus. Yes, of course, not every welder can make a neat weld.

Of course, welding of bridge structures and building floors should be performed by professionals. But even an amateur can make a garden gate or a frame for a decorative composition from metal rods. If he has a special device.

It turns out that making such a homemade welding unit is quite simple and craftsmen came up with the design a long time ago.

Do-it-yourself resistance welding can be done quite quickly if a person has basic knowledge and skills in electrical engineering.

To manufacture the unit, you will need the following materials and accessories:

- power transformer;

- switch;

- timer;

- copper rod with a diameter of 1.5 cm;

- copper wire with a diameter of one centimeter.

If you do not have any skills in radio engineering, it is best to purchase a time timer at a specialized store.

Manufacturing a transformer for resistance welding

The most important part of the apparatus intended for resistance welding is the transformer. This unit allows you to obtain the required voltage for welding work.

The transformation ratio must be high; for this reason, for the manufacture of this element of the welding machine, it is best to use devices that are included with microwave ovens. The power of this component of the unit must be at least one kilowatt. In microwave ovens, as a rule, a unit with a power of up to 4 kW is used.

The transformer is removed from the microwave, and the secondary winding is removed from it.

To manufacture a welding transformer, only the primary winding of the unit is required. When removing the wire, all disassembly operations should be carried out very carefully.

Types and characteristics of resistance welding

This is required so as not to damage the copper wire of the primary winding and the magnetic circuit during the manufacturing process.

After carrying out preparatory stage The secondary winding is being manufactured. At the output of the unit, you need to obtain a current of 1000 A. For this purpose, a copper wire with a diameter of 1 cm is used. When manufactured from such a copper wire, 2-3 turns are obtained in the device. The voltage at the output of the power device is about 2 volts.

The use of such a transformer in a welding machine for resistance welding allows you to work with metal up to 5 mm thick. After winding the copper wire, the direction of the windings is checked; in addition, at this stage of manufacturing, the presence of short circuits in the transformer is checked. In the absence of the latter, proceed to the further manufacturing process. When using two or more transformers in the design of a welding device, the output current is checked - it should not be more than 2000 A.

If this value is exceeded, the current should be reduced, since high strength current provokes significant changes in the household electrical network during the operation of the device. After winding the copper wire and checking the parameters of the transformer, it is ready for use.

Manufacturing of electrodes for resistance welding machines

Electrodes are made from thick copper rods, the diameter of which is 1.5 cm.

When making electrodes, you must strictly adhere to the rule that the thickness of the electrode must be no less than the wire used in the secondary winding of the device.

If you use a low-power transformer, you can use tips from a pair of soldering irons as welding electrodes. Soldering iron tips have one undoubted advantage - they are durable and, thanks to this, will last for a long time.

The wires connected to the electrodes must have a minimum length, this is required in order to reduce current losses. To connect the wire to the electrode, a copper tip or a hole in the electrode made with a drill is used.

The wire is attached to the electrode using a bolted connection. For better contact, it is best to solder the wire to the tip; this will prevent the oxidation process and current losses during the oxidation process.

The advantage of a bolted connection is the ability to quickly remove the electrodes. When making a connection by soldering, if it is necessary to replace the electrodes, the joints will need to be re-soldered, which takes a lot of time.

Welding process control and welding machine infrastructure

Do-it-yourself resistance welding requires equipment with a control lever and switches.

The quality of welding of metal products is ensured not only by the current strength, but also by the compression force. For this purpose, the device is equipped with a lever. Compression force plays a particularly important role when welding thick sheets of metal.

When welding at home, the compression force must be at least 30 kg, for this reason the lever must be made of the appropriate length. This will ensure ease of use of the welding machine and high quality welding of parts. The length of the lever handle to ensure the compression ratio should be 60 cm.

The lever is attached 3/4 from the bottom. Therefore, the arm to clamp ratio is 1:10. With this design of the lever, if a pressure of one kilogram is applied to the lever, a pressure of ten kilograms is applied to the metal.

The switch is installed on the primary winding of the transformer, since a large current circulates in the secondary winding of the device, and the resistance of the switch in the circuit to the secondary winding will lead to loss of current.

For ease of operation, the switch is located on the lever handle, this allows you to feed electrical energy onto the device only after the metal has made contact with the electrodes of the device. This placement of the switch allows for significant energy savings due to the absence of idle operation of the device.

When working with thin metal, it is best to install a timer in the control circuit of the welding device.

The timer allows you to regulate the operating time of the unit; to cool the device and its components, you can use a cooler from an old desktop computer.

After completing assembly of the device, it should be tested.

RESISTANCE WELDING METHODS

There are butt, spot and seam welding.

Butt welding

Butt welding

Contact butt welding is a resistance welding method in which workpieces are welded over the entire contact area.

The resistance butt welding diagram is shown in Fig.1. Weldable workpieces 1 secured in the clamps of the jointing machine. Clamp 3 installed on a fixed plate 2 , clamp 4 - on a movable plate 5 . Welding transformer 6 connected to the plates by flexible busbars and powered from an alternating current network through a switching device. Using a pressure mechanism, the movable plate 5 moves, the welded workpieces 1 are compressed under the influence of force R.

There are resistance butt welding and flash welding.

Resistance welding — butt welding with heating of the joint to a plastic state and subsequent upsetting. Reflow welding called butt welding with heating of the joint until melting and subsequent upsetting.

The parameters of the resistance butt welding mode are the current density j(A/mm2), specific compression force of the ends of the workpieces p (Mpa), current flow time t(c) and installation length L(mm).

Installation length L is the distance from the end of the workpiece to the inner edge of the electrode of the butt machine, measured before the start of welding.

For correct formation of the welded joint and high mechanical properties connection is necessary for the process to proceed in a certain sequence. Joint graphical representation of current change I and pressure R when welding is called a cycle or cyclogram of a contact machine .

Resistance butt welding.

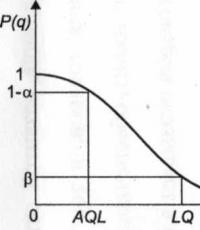

The resistance butt welding cycle is shown in Fig. 2.

The resistance butt welding cycle is shown in Fig. 2.

When resistance welding, the cleanly machined ends of the workpieces being welded are brought into contact and compressed with force R.

Then turn on the welding current I. After heating the metal in the contact zone to a plastic state, increase the force (upsetting the workpieces) and simultaneously turn off the current. In this case, plastic deformation of the metal occurs at the joint and the formation of a joint in the solid state.

When resistance welding, it is difficult to ensure uniform heating of the workpieces over the cross section and sufficiently complete removal of oxide films. Therefore, resistance welding is used to a limited extent.

This method welds identical workpieces of simple shape (circle, square, rectangle with a small aspect ratio) of small cross-section (up to 250 mm2) from low-carbon and low-alloy structural steels and non-ferrous metals and alloys.

Flash butt welding Unlike resistance butt welding, it does not require preliminary preparation of the ends of the workpieces.

Flash butt welding has two varieties: continuous and intermittent flash.

With continuous reflow the workpieces are brought together with the welding current turned on and very little force. At the beginning, the contact of the workpieces occurs over separate small areas through which a high-density current passes, causing melting of the workpieces as a result of the continuous formation and destruction of contacts - jumpers between their ends.

As a result of melting, a layer of liquid metal is formed at the end. Then the upset is carried out and the current is turned off. During precipitation, the liquid metal, along with impurities and oxide films, is squeezed out of the joint, forming a burr.

The compound is formed in a solid state. The continuous reflow welding cycle is shown in Fig.3.

With intermittent reflow

the clamped workpieces are brought together under current, brought into brief contact and again separated by a short distance.

With intermittent reflow

the clamped workpieces are brought together under current, brought into brief contact and again separated by a short distance.

By repeating the approach and separation one after another, the entire section is melted. Then the current is turned off and the workpieces are upset.

Flash butt welding can be used to weld workpieces with different sections, both simple and complex shapes, from homogeneous or dissimilar metals. Continuous fusion welding is used to connect workpieces with a cross-section of up to 1000 mm2, and intermittent fusion welding - up to 10,000 mm2.

The most typical products welded by butt welding are elements of tubular structures, wheels, rings, rails, reinforced concrete reinforcement, etc.

SELF-TEST QUESTIONS

7. What is called butt welding?

8. What is the sequence of technological operations during welding

resistance and reflow?

What is the difference between resistance butt welding and flash butt welding?

10. What is the difference between continuous flash butt welding and intermittent flash butt welding?

In what cases is it advisable to use resistance butt welding? And when is reflow (continuous or intermittent)?

Resistance spot welding

Spot welding is a type of resistance welding in which workpieces are joined at separate points.

Before welding, the surfaces of the workpieces are thoroughly cleaned of dirt, oil and oxide films (with an emery wheel, a wire brush or etching).

In spot welding (Fig. 4), overlapped workpieces are compressed by electrodes connected to a welding transformer, when turned on, the workpieces at the point of contact are heated by electric current until a molten zone (the core of the point) appears.

Then the current is turned off, and the compression forces are kept constant for some time so that the crystallization of the molten metal of the point occurs under pressure. This prevents the formation of shrinkage defects - cracks, looseness, etc. In some cases, to improve the structure of the weld point, the compression force before turning off the current is increased (forging the point).

Spot welding, depending on the number of simultaneously welded points, can be one-, two-, or multi-point.

According to the method of supplying current, spot welding can be double-sided ( Fig.4a) and one-sided ( Fig.4b)

According to the method of supplying current, spot welding can be double-sided ( Fig.4a) and one-sided ( Fig.4b)

In double-sided welding, the current is supplied to the upper and lower workpieces; in single-sided welding, the current is supplied to one of them.

To increase the current density in the connection zone with one-sided current supply, the workpieces are placed on a current-carrying copper pad. Single-sided welding is used when access to one of the workpieces is difficult, as well as when it is necessary to increase the productivity of the process, since in this case two points can be welded simultaneously.

One of the spot welding cycles, the cycle with forging, is presented in pic 5.

The entire welding cycle consists of four periods: compression of the workpieces to be welded by electrodes, turning on the current and heating the contact point to a melting temperature with the formation of a cast core point; turning off the current and increasing the compression force (forging the point); removing force from the electrodes.

The entire welding cycle consists of four periods: compression of the workpieces to be welded by electrodes, turning on the current and heating the contact point to a melting temperature with the formation of a cast core point; turning off the current and increasing the compression force (forging the point); removing force from the electrodes.

The spot welding mode can be soft or hard.

The soft mode is characterized by a relatively low current density (j=80...160A/mm2) and a long flow time (T=0.5...3s) at a relatively low specific pressure (p=15...40MPa). The hard mode is characterized by high current density (j=160...350A/mm2), high specific pressure (p=40...150MPa) and short current flow time (t=0.001...0.1s). Soft modes are used mainly when welding carbon and low-alloy steels, hard modes - corrosion-resistant steels, aluminum and copper alloys.

Spot welding can be used to weld sheet blanks of the same or different thickness, intersecting rods, sheet blanks with rods or profile blanks (angles, channels, etc.) made of low-carbon, carbon, low-alloy and corrosion-resistant steels, aluminum and copper alloys.

The thickness of the metals being welded is 0.5-6 mm, and in some cases can reach 30 mm.

Multi-spot resistance welding - a type of resistance welding, when several points are welded in one cycle.