Machine for the production of plastic tableware. Production of disposable tableware as a business: list of equipment, description of manufacturing technology, nuances of business organization. Mandatory requirements for the premises

Bogdana Zhuravskaya

Production disposable tableware- a promising and profitable line of business for an entrepreneur who is not afraid of a high barrier to entry into the market. Along with significant capital investments, you must be prepared to overcome a number of risks. The main one is the lack of a large number of highly qualified technologists and open information about the nuances production process. In addition, the environmental movement is becoming increasingly popular in our country. This means that it is necessary to build your activities taking into account the fact that sooner or later the enterprise will have to be reformatted to produce a biodegradable product.

In anticipation of the start

There are many types of disposable tableware. Conventionally, products can be divided into several large groups: plastic, paper, wood and so-called environmentally friendly. The latter category includes both tableware made from biodegradable plastic and the latest developments, when cups and plates are made from a variety of raw materials such as cereals (edible tableware), reeds, corn starch, leaves, bamboo, etc.

Before launching a project, an entrepreneur must clearly indicate what type of product he will produce. There are no universal lines at the moment, and the launch of an enterprise with a large number of installations for products from different materials will require huge investments. Another difficulty is getting effective technology production of disposable tableware. Find detailed information Open access is not easy, and qualified technologists are worth their weight in gold. Therefore, the easiest way to establish the process is to train personnel from the equipment manufacturer.

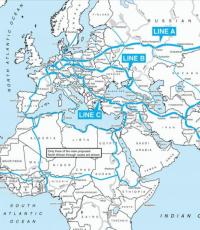

Next, agreements should be concluded with suppliers of raw materials. There are not many of them on the territory of the Russian Federation, so you can consider options for cooperation with foreign partners. In any case, it is not advisable to focus on only one manufacturer, because a supply failure can cause downtime for a new enterprise.

Having decided on the above questions, you can begin searching for equipment and developing project documentation. As already mentioned, the financial barrier to entry into the market is quite high. Thus, only the purchase of a minimum set of equipment for the production of disposable plastic tableware will require about 12 million rubles. Having a well-developed business plan in hand, it makes sense to start working using investors’ funds.

Basic risks

Potential clients they are in no hurry to enter into preliminary agreements with a new manufacturer and are ready to consider proposals only if they have the required volume of finished products and a package of documents confirming the goods’ compliance with GOST and SanPiN requirements.

As for competition, you will have to deal with a pool of domestic and foreign companies, most of which have strong positions in the market, have certain experience and, importantly, customer trust. For example, Chinese manufacturers, thanks to huge volumes, have the opportunity to offer very attractive price offers.

Another conditional difficulty is the seasonal demand for products. Expanding the range will help maintain balance.

Main consumers of disposable tableware

Among the wholesale buyers that a manufacturer of disposable tableware needs to target:

- , canteens, pizzerias and other establishments Catering;

- seasonal takeaway food stalls;

- food delivery services;

- markets of various formats, catering companies with their own culinary production;

- agencies for organizing picnics and outdoor holidays;

- enterprises engaged in the sale of vegetables and fruits.

As you can see, the list of opportunities for selling products is quite wide. An entrepreneur just needs to create a profitable offer and convey information about it to as many partners as possible.

Types of disposable tableware

To comprehensively satisfy consumer demand, the manufacturer’s assortment must include disposable tableware for drinks, soups, main courses, snacks, packaging of various products, as well as salad bowls, cutlery, straws, plastic lids for glasses for take-out drinks and stir sticks.

Several types of raw materials can be used to manufacture products: plastic, including its degradable variety, special paper, wood. In addition, dishes made from natural materials.

Disposable plastic tableware

Plastic utensils have a number of advantages. It is convenient, hygienic, practical, and very inexpensive. The versatility of the material allows us to produce a wide range of products - plates, cups, cutlery, straws, stir sticks of various colors, shapes and sizes. If necessary, you can apply a logo or a bright design.

Equipment for the production of plastic tableware

A standard disposable tableware production line contains:

- thermoforming machine;

- extruder;

- mold;

- compressor.

The minimum cost of a set of equipment is about 3 million rubles. costs for the first batch of raw materials - from 100 thousand rubles.

Manufacturing technology + Video

Two types of plastic are used to produce tableware:

- foam propylene (durable, plastic, resistant to heat, utensils made from it can be used for hot dishes and drinks, designated PP with the number 5);

- polystyrene (products cannot withstand heat, food cannot be stored in them, designated PS with the number 6).

The raw materials for the production of plastic tableware are granular polymers that look like balls of. The price per ton of granules ranges from 45-100 thousand rubles, which depends on the brand, diameter and other characteristics.

This raw material is used by full-cycle enterprises where granules are melted and film is made from which plastic tableware is produced. In an incomplete cycle, the manufacturer uses finished film costing 100-190 thousand rubles. per ton.

The full production cycle of disposable tableware includes the following stages:

- Melting granules. White or if we're talking about For the production of colored dishes, multi-colored balls are placed in an extruder, where the raw material is heated to the melting point with constant stirring by a screw press.

- Film making. Having reached the desired consistency, the mass is fed to a press, through which a plastic sheet 2 mm thick is obtained.

- Shaping products. The film enters the thermoforming unit, is heated to a plastic state and drawn into molds.

- Cutting out elements. The whole web with the formed dishes is moved to the trimmer, where the individual elements are separated from the whole web. Plastic pieces are sent for recycling.

- Next, the dishes are sorted and fed to the conveyor, where they are modified - logos are applied, edges are folded, etc.

- Package. The machine selects the required number of products and places them in film.

A similar method is used to produce tableware from biodegradable plastic.

Video how to do it:

Disposable tableware made of bioplastic

Disposable tableware made from biodegradable plastic is marketed as “green”, but the material, although to a lesser extent than its biostable counterpart, still pollutes environment, since decomposition releases methane and carbon dioxide. However, supporters of an eco-friendly lifestyle welcome this decision on the principle of choosing the “lesser evil” and are happy to use the product.

Main competitors

Among the giants of the disposable tableware market, the following companies can be noted: U2B, My Dishes, GORNOV GROUP, Plastic-Step, Mysteria, Papperskopp Rus, Huhtamaki, Trial Market, PapStar, The Paper Cup Company.

One of the most profitable areas of business is the production of disposable tableware. People use plastic dishes when having picnics outside the city, on various trips, at children's parties, so the demand for this product is not decreasing, and this type of product will remain in demand for many years to come. The difference between this type of tableware and porcelain and glass is its light weight, ease of transportation and low price.

Our business assessment:

Starting investment - 20,000,000 rubles.

Market saturation is high.

The difficulty of starting a business is 8/10.

Reasons for choosing this niche

Many people are mistaken, claiming that the production of plastic tableware is exclusively seasonal business. In practice, entrepreneurs have proven that this type of business is year-round, the reason for this is that people use utensils intended for one use all the time.

This type of business is highly profitable. The main advantages of plastic utensils include their hygiene and safety. Using this type of plates, containers, glasses and cutlery saves time for putting things in order after various special events.

Business in the production of disposable tableware involves the use of high-tech equipment that allows you to obtain goods High Quality. The production line for disposable tableware, which is located at the enterprise, allows us to produce glasses of various capacities, as well as bowls, plates of different sizes, straws for drinks, cutlery and other disposable products.

An entrepreneur should understand that there are the following types of clients:

- people buying goods for seasonal picnics, celebrations, events;

- owners of catering outlets, lunch delivery services, cafes, as well as owners of drinks and oxygen cocktails.

For second clients it is carried out more often wholesale trade disposable tableware.

It is noted that disposable plastic tableware is difficult to sell in a “young” business at first, since it is necessary to form a customer base. Only a high quality product can attract potential buyers. It is important to hire an experienced advertising manager who can promote the business and form a customer base.

Important stages of production organization

In order for a business to make a profit, it is necessary to complete several important steps:

- register a business;

- buy equipment;

- find employees.

How to register a business?

To open a plant for the production of disposable tableware in Russia, it is necessary to legally register soybeans entrepreneurial activity by completing the relevant documents. When choosing between an individual entrepreneur and an LLC, you should focus on the expected profit from production. The form of business in the form of an individual entrepreneur is registered if a small production is planned. If an entrepreneur is planning to found big business, then an LLC (limited liability company) is formed. The advantages of the latter include greater trust of partners in the founder of the production, a simplified taxation system, as well as the possibility of receiving significant discounts on raw materials for the production of disposable plastic tableware.

To sell manufactured products, it is mandatory to obtain a certificate that confirms the product’s compliance with established standards according to GOST.

Where should the production be located?

The workshop should be located outside the city. The mini plant has an area of about 100 m². Of these, 70 m² is an industrial workshop, 15 m² is a warehouse, the remaining 15 m² is utility rooms and a bathroom. For large production, an area of 600 m² will be sufficient.

The room where disposable plastic food utensils will be produced must have the following parameters:

- 3-4 m – minimum ceiling height;

- the floor is poured with concrete or tiles are laid on it;

- three-phase electrical network;

- the presence of ventilation ducts, sewerage and water supply;

- treating walls with fire-resistant liquids up to 2 meters from the floor.

The plant should also be equipped with utility and storage facilities.

What raw materials need to be purchased?

Raw materials for disposable tableware must be of high quality. You will need polystyrene, it is sold in granules, its price varies within 25 thousand rubles per ton. In order for the products to be colored, you should buy color additives. Another material is also needed for the production of disposable tableware − polyethylene film. If you compare store shelves with plastic and paper tableware, you will notice that the cost of the latter is quite high, so the demand for it is somewhat lower than for its plastic counterparts, which is why the most profitable business will be the production of products from thermoplastics.

Raw materials for disposable tableware must be of high quality. You will need polystyrene, it is sold in granules, its price varies within 25 thousand rubles per ton. In order for the products to be colored, you should buy color additives. Another material is also needed for the production of disposable tableware − polyethylene film. If you compare store shelves with plastic and paper tableware, you will notice that the cost of the latter is quite high, so the demand for it is somewhat lower than for its plastic counterparts, which is why the most profitable business will be the production of products from thermoplastics.

Difficulties in recruiting workers

The search for personnel can be carried out through advertisements on the Internet and newspapers, but finding responsible employees in this way is quite difficult. There are no special training courses for managing the production of disposable tableware. However, almost all equipment suppliers offer entrepreneurs training for their personnel in favorable conditions. You need to enter into an agreement with them after-sales service technology.

Selection of equipment for production

The initial question that a businessman asks is what equipment to buy for the production of disposable tableware. The highest quality lines are those produced in Germany and the USA, but their price is high, so they can be replaced with analogues from Korea. However, they have a lower production capacity. For production you will also need an injection molding machine. To obtain blank sheets from granulated raw materials, you need to purchase an extruder. You will also need molding machines for the production of disposable tableware and a compressor.

The production cycle can be complete or incomplete. The first involves melting the granules and making a film. The second excludes preparatory stage its production, since it is purchased as raw materials, in the form of rolls. Therefore, the following set of equipment is required:

- an automatic machine designed for stacking and packaging products;

- granulator;

- extruder

Subsequent equipment is purchased in accordance with the selected type of cookware. You will need the following products:

- automatic machine for bending the top edge;

- packing machine;

- printers for applying images, etc.

To make thick cutlery, pourable molds are needed. A diverse assortment guarantees greater business success, so you should purchase lines that integrate with big amount thermoforming machines. This set of equipment will allow us to produce various types of products.

Approximate cost of equipment

The price of the equipment is high; for example, the injection molding machine alone costs about 1 million rubles. Entrepreneurs estimate the cost of entering the disposable tableware market at least 20 million rubles. This is due to the fact that it will not be possible to limit yourself to one machine if you plan not only to win your share of the market, but also to develop further. Most of the costs are the purchase of an extruder that produces sheets from granulate.

The price of the equipment is high; for example, the injection molding machine alone costs about 1 million rubles. Entrepreneurs estimate the cost of entering the disposable tableware market at least 20 million rubles. This is due to the fact that it will not be possible to limit yourself to one machine if you plan not only to win your share of the market, but also to develop further. Most of the costs are the purchase of an extruder that produces sheets from granulate.

Disposable tableware with a custom logo can also be sold. This type of business is especially relevant nowadays for holding various kinds of celebrations, presentations and events. Glasses are an excellent advertising medium. A corporate logo on dishes helps maintain corporate style and promotes goods or services on the market.

Stages of production technology

Depending on what products are planned to be produced, two technologies are distinguished: molding and casting. The latter method produces dishes with thick walls. The casting process takes a long time, Money. It is worth noting that the weight of a regular glass with a volume of 200 ml is 3 g, made by injection molding - up to 10 g.

There is a more cost-effective technology for the production of disposable tableware, molding, with the production of up to 30 million cups per month, which consists of the following steps:

- The purchased early raw materials are sent to the extruder.

- In the extruder, the granules melt and the resulting mass is mixed. Forming the desired consistency, the viscous liquid passes through the press, resulting in a plastic sheet approximately 2 mm thick. On at this stage a uniform thickness of the future dishes is formed.

- The film is heated in a 3-meter oven.

- The resulting mass enters a thermoforming machine, where the shape of the products is formed.

- Glasses, plates and other products are fed into the trimmer, where they are cut from the general canvas using a die-cutting press.

- Film scraps are recycled for recycling, so production is waste-free.

- The trimmer distributes the products into a special apparatus, which stacks them and sends them to the conveyor belt.

- The belt transports the dishes for packaging or subsequent transformation.

Thus, the business of producing disposable tableware is profitable and profitable, but requires large financial investments.

In today's world, the production and sale of disposable tableware is constantly growing, and this trend has been observed for a number of years. The popularity of such utensils is quite justified - glasses, plates, forks and spoons made of plastic are very inexpensive, absolutely safe for health and hygienic (after use they are simply thrown away). Disposable tableware is of particular importance for enterprises fast food, in which it is used extremely actively and in huge quantities.

The history of plastic tableware in the USA

The birthplace of plastic tableware is the United States of America. It was in this country, in the middle of the last century, that a certain William Dart invented a plastic cup, the very first in the world. He patented his revolutionary invention and founded the Dart Container Corporation. It currently occupies a third of the entire US disposable packaging market. Somewhat later, in addition to plastic glasses, plates, forks, spoons and knives began to be produced. The production of disposable tableware in Moscow and other cities of our country began only in the mid-90s of the last century. Before this, it was imported from abroad, which at a certain point became economically unprofitable. Now in Russia there are many large and small enterprises producing disposable tableware, which almost completely cover the needs of the domestic market for it.

Equipment for the production of plastic tableware

Modern technology for the production of disposable tableware involves the use of specialized equipment, which includes:

- Extruders;

- Thermoforming machines;

- Automatic production lines.

Extruders are necessary in order to produce plastic sheets, from which dishes are subsequently formed. This process is carried out using thermoforming machines. The largest and modern enterprises are equipped with specialized automatic production lines with high performance. As for the cost of equipment for the production of plastic disposable tableware, it is quite high. For example, a new high-performance extruder made in Europe costs about $500,000, while a thermoforming machine costs about $40,000.

Raw materials for the production of plastic tableware

In Russia, the main raw materials for the production of disposable plastic tableware are polystyrene and polypropylene. These materials meet all sanitary and hygienic standards and do not emit any substances harmful to human health. They are most often delivered to production in the form of granules.

Probably every person in our country has encountered disposable tableware. And it doesn’t matter at all what it was made of: paper or plastic. Before you find out what equipment you should purchase for the production of disposable tableware, let’s figure out why this is worth doing.

Advantages of the presented products

So, among the advantages we can highlight the following:

- ease of use;

- very low cost;

- environmental Safety;

- convenience;

- high demand.

Naturally, equipment for the production of disposable tableware cannot be called simple, since it is capable of performing dozens of different operations. However, the amount of possible income completely covers any disadvantages.

What are the dishes made of?

Naturally, in order to stamp products, you must first purchase raw materials. For production, you can use both paper and polyethylene. Moreover, in the second case, production is cheaper. However, paper dishes are safer.

The purchase of raw materials should be made from several trusted suppliers. In addition, recyclable materials are excellent for such production, the cost of which is very low. If you decide to choose polyethylene, then keep in mind that making dishes from it is quite difficult. However, the products are more durable and can be used in the microwave.

What equipment is needed for the job?

In order to organize your own workshop, you need to know what equipment to purchase for the production of disposable tableware. So, you will need:

- injection molding machine (designed to work with polypropylene and polystyrene);

- thermoforming machine;

- extruder - thanks to it, flat sheets can be obtained from polyethylene granules;

- packing table;

- crusher - used for crushing recyclable materials;

- chiller - this machine for the production of disposable tableware provides cooling of workpieces;

- compressor.

In principle, this equipment is quite enough to start a business. Then you can expand and buy more powerful and functional machines.

How to choose the right equipment?

This question is not too difficult. First you need to decide on the parameters of the machines, and then look for a suitable model. For example, to begin with, low-power equipment with average performance will be more sufficient for you.

However, even it is not that cheap. Therefore, to begin with, it is quite possible to use used cars. Naturally, they should be in good condition, and not break down every week. But here it depends.

If you decide to purchase a new line, please note that you should order a machine for the production of disposable tableware only from a trusted manufacturer who enjoys a positive reputation.

When choosing, try to carefully consider all the devices. The seller must provide you with all necessary accompanying certificates.

Features of the production of polyethylene tableware

It is cheaper both in production and on the market. The manufacturing process of such material is quite complicated. It consists of the following stages:

1. To begin with, the sorted raw materials in the form of granules are thrown into an extruder, where under the influence of high temperature it turns into a homogeneous semi-liquid mass. Mixing inside the bunker is carried out using an auger.

2. The resulting mass is squeezed out through a thin slit. The result is a long and wide sheet, the thickness of which varies within a few millimeters. It all depends on how the shafts are configured, and they must work accurately and correctly. If you have a functional extruder, then with its help you can get a multilayer film. In any case, its thickness should be the same along its entire length.

As you can see, the manufacturing process is quite complicated. The machines must be operated by experienced operators who can operate automatic system using the remote control. Naturally, strict safety rules must be observed during operation.

Features of manufacturing dishes from laminated cardboard

First of all, it should be noted that equipment for the production of disposable paper tableware is produced only abroad. The fact is that such a business is not very popular in our country, due to the fairly high cost of primary raw materials. However, if you still decide to do this, then look for German, American, Korean or Chinese devices.

The production of disposable tableware is becoming increasingly important in the world. And although purchasing equipment is an expensive undertaking, and when drawing up a business plan you need to carefully analyze the market, it is still a promising project that is worth paying attention to.

It is advisable to familiarize yourself with the nuances of the work of such a workshop in practice. A novice entrepreneur without basic skills will make too many mistakes that will ruin the project at the start. But having enough experience, you can open a mini-factory for the production of plastic cups, and then gradually expand the range.

Business relevance

According to statistics, there has been an increase in demand for disposable tableware around the world within 10-15% annually. This suggests that people often prefer it. The advantages are obvious:

- Can be used once and then thrown away.

- Low price.

- With the help of multi-colored elements it is possible to create a festive atmosphere in any conditions.

- Such dishes are light and do not take up much space if you have to take them with you outdoors.

- Convenient to use for any purpose.

True, an increasing variety of such products is appearing on the market and competition among entrepreneurs is growing. On the one hand, this Chinese suppliers plastic dishes, the cost of which is very low. On the other hand, there is the emergence of more environmentally friendly varieties, for example, paper cups. But if you organize the production of safe and cheap products, you can conquer your niche.

First you need to decide on your main competitors, study their strengths and weak sides. Take into account imported plastic tableware, which is still in great demand. Draw up a competent business plan and think over the range of products offered. For example, disposable cups of different sizes and volumes are rightfully considered the most common. Only after this proceed to the organizational part.

Paperwork

To open a mini-workshop, you must first register as entity. The advantages of an LLC over an individual entrepreneur are significant:

- Such a company inspires more confidence both among suppliers of raw materials and equipment, and among wholesale buyers.

- It is possible to recover VAT on purchases.

- If it fails, the company risks only its authorized capital.

- It's easier to get a loan from a bank.

When registering, indicate OKVED code 25.24.2. Various licenses are not required for activities, but the premises itself and the quality of the products produced must comply with GOSTs and the standards prescribed in SanPiN. Before starting a disposable tableware business, be sure to study the following documents:

- GOST R 50962-96 – general technical specifications production of plastic products.

- GOST 15820-82 – clarifying the quality standards of copolymers of styrene and polystyrene, on the basis of which plastic tableware is created.

- GN 2.3.3.972-00 - adopted instead of SanPiN 42-123-4240-86, which establishes requirements and quantity indicators chemical substances in similar materials.

- SP 2.2.2.1327-03 – describes technological process and hygienic requirements for the operation and condition of equipment.

- GN 2.2.4.1313-03 – which talks about harmful substances in the air in the workplace.

To obtain permissions for production activities from the SES, fire inspectorate and Rospotrebnadzor, you need to prepare the premises accordingly, purchase equipment and release the first batch of goods, which must undergo thorough quality control. Only after this can you begin to implement the idea in practice.

Workshop setup

When installing all the equipment necessary for the production of disposable tableware, you need to select and prepare the room in a certain way. It is important to consider the following requirements:

- The ceiling height should be at least 4.5 meters, and only in the absence of an extruder and granulator can you get by with 3.5 m.

- The floor must be poured with concrete or laid with durable tiles.

- The walls are covered with fire-resistant material that can be easily washed.

- Be sure to install good ventilation.

- The electrical network must be three-phase and can withstand the high loads of all equipment.

- Don't forget about water supply, heating and other communications.

The entire building is divided into separate zones:

- working;

- administrative;

- bathroom and shower for staff;

- wardrobe;

- warehouses for raw materials and finished products.

Make sure that the workshop has convenient access roads for unloading goods. It is better to rent or purchase such premises outside the city or in its industrial part. The total area should be about 500 square meters. m.

Equipment selection

A full-fledged automated line for the production of disposable tableware consists of the following elements:

- Granulator.

- Extruder.

- Crushers.

- Thermoforming press.

- Automatic product stacking machine.

- Conveyor.

- A machine for bending the top edge of a glass.

- Printer for applying an image.

- Compressor.

- Self-filling molds for cutlery.

It is not necessary to purchase all of their varieties at once. You can build a line gradually, adding individual elements as your business develops and returns starting investments. You can only start with an automatic product stacking and packaging machine and a thermoforming line. By purchasing ready-made rolls of thin film, you will do without installing other elements.

Please note that equipment manufacturers offer different models, capacities, and a variety of shapes, and this, in turn, significantly affects the cost. Depending on your financial capabilities and the desired volume of production of disposable tableware, you need to make a choice.

It is believed that German and Austrian devices are the most powerful and are the ones worth purchasing when creating a productive automated line that produces several million products per month. But to start, you can spend 3-4 times less and opt for Korean or domestic cars. Then production volumes will be lower, but equipment costs will also be affordable.

Raw material base

Plastic disposable tableware is made from two main components:

- Polypropylene is resistant to fats, oils, alcohol, products made from it can be placed in a microwave oven, and they are also allowed to be used for baby products. But when working with this material, it is necessary to strictly adhere to the technology parameters so that its quality characteristics do not deteriorate.

- Polystyrene - it is much easier to work with, but has lower performance during operation.

Individual entrepreneurs began to produce, but the cost of laminated cardboard and products made from it is quite high. Therefore, such a business is still losing in competition.

When searching for suppliers of polystyrene and polypropylene, you can contact several existing large enterprises who are engaged in their production. But there are certain disadvantages. With larger orders, small customers will have to wait too long for the material, which threatens frequent workshop downtime.

Therefore, it is worth establishing other delivery channels. For example, pay attention to factories that collect recyclable materials and process them. And although the quality of such material is significantly lower, this can be a way out in finding a permanent and reliable supplier. Or find a foreign manufacturer willing to offer the material at an affordable price. It is important to control the quality of the original raw materials. It must comply with GOST 10354-82.

Technological process

When creating plastic utensils, the material goes through the following stages:

- Polyester in the form of granules is fed into the extruder. If you want to diversify the color scheme of the product, you can add different shades.

- The raw material is heated to high temperatures, at which it begins to melt, and mixed, achieving a homogeneous mass.

- Then it is passed through a press, which ensures the thickness of the finished film is 2 mm. It is very important to ensure that the machine always produces a uniform web.

- Such a roll is sent to a thermoforming machine, which involves the creation of one or another product (glasses, plates, etc.).

- Here the material is again subjected to high temperatures and, due to vacuum action, acquires the desired shape.

- Next, the workpieces go to the trimmer, where they are cut to size.

- Using a conveyor, they move to a packaging machine or printer to apply a logo, design, advertising, etc.

- For glasses and plates, you need to additionally pass the products through a machine that bends the edges.

- At the end, the goods are packed into large bags.

Staff

Due to the fact that the line is fully automated, there is no need to hire a large number of people to monitor its operation. Depending on the volume of production, a different number of employees is needed. For a medium-sized workshop it is enough to have on staff:

- Technologist - specialist with higher education and experience in this field, it is quite difficult to find such a person, but its presence is mandatory to maintain product quality.

- Equipment adjusters should also be trained additionally or find professional technicians.

- Ancillary workers.

- The cleaning lady.

- Accountant.

- Client Relationship Manager.

To deliver goods to customers yourself, it is also advisable to hire a loader and driver. To save costs, you can perform some functions, for example, accounting, management, product sales, yourself.

We are looking for buyers

It is not enough just to produce a quality product. We still need to find through which channels to sell disposable tableware. From advertising, you can use all available resources - media, Internet, advertisements. But it’s better to establish personal contacts with the owners:

- Catering establishments.

- Supermarkets.

- Specialized stores selling relevant products.

- Wholesale bases.

- Companies involved in food preparation and delivery.

- Vending machines.

- Larkov.

- Offices.

- Educational and other government institutions.

- Confectionery companies.

- Organizations for organizing holidays and corporate events.

- Catering agencies, etc.

It makes sense to hire a marketing and sales specialist, then the activities of your company will quickly pay off due to large wholesale orders and sales of finished products.

![]() Download for free as a sample.

Download for free as a sample.

Financial part

Opening a mini-workshop for the production of disposable tableware will require large investments. Let's list the main expense items.

The cost of one unit of product is on average 0.25 rubles. If you sell disposable tableware for 0.35 rubles, then with a production volume of 10 million units per month, you can achieve a net profit of 1,000,000. Even taking into account regular deductions, after 3-4 months you can achieve full payback for the project.

Video: production of disposable tableware.