About the input devices of the gas turbine engine.... What is the use of an air intake on the hood, how to install it yourself Air intake elements

KAMAZ engines require a large volume of air to operate, so they are equipped with a high-performance power supply system in which a special component, the air intake, is responsible for the air supply. Read about the diesel power system and air intake, its role, structure and operation in this article.

The role of the diesel engine air supply system

Combustion of any fuel is possible only in the presence of air, which serves as a source of oxygen necessary for combustion. Therefore, the engine includes an air supply system that solves several problems:

Air extraction from the atmosphere;

. Air purification from pollutants;

. Air supply and distribution among the cylinders.

It should be noted that often the air supply system is not separated into a separate system, but is considered as one of the components of the engine power supply system, which also includes the fuel system. The exhaust gas exhaust system also interacts with the power system, which acts as a source of vacuum for the operation of some units. But here it will be more convenient to consider the engine air supply system separately.

Design and operation of the air supply system

The air supply system for KAMAZ engines has a simple structure; it includes several main components:

Air intake and air intake pipe (on some models);

. Seal;

. Air filter with inlet and outlet air duct;

. Engine air intake duct;

. Dust suction pipe from the air filter;

. Some models have a turbocharger (more precisely, only its compressor part).

The system operates as follows: atmospheric air through the air intake through the air duct enters the filter, where it is cleaned of dust and then sent either directly to the engine cylinders, or first to the turbocharger, and then under pressure into the cylinders. At the same time, in two places the air supply system interacts with the exhaust system: firstly, an air filter is connected to the exhaust pipe, and secondly, the exhaust gases ensure rotation of the turbocharger.

Note that KAMAZ vehicles use three schemes for constructing an engine air supply system:

With a vertical air filter - this scheme was used on older truck models; it required the use of a developed air duct system, since the filter was usually mounted quite low in relation to the engine;

. With a horizontal air filter and a high-mounted air intake (on a long air duct) - the most common design today, in which the filter is located just above the engine and the air intake is installed at the rear of the cabin;

. With a horizontal air filter and a low-mounted air intake - this scheme is used on dump trucks, the air intake is installed directly on the air filter, and is located in the space between the cab and the front of the dump truck.

Some details of the air supply system need to be said in more detail.

Seal. The need and importance of this part is dictated by the design features of the KAMAZ vehicle cabin. Typically, the air intake is mounted directly on the cab, in its rear part, and the air filter and its inlet air duct are mounted on the frame. But the KAMAZ cab tilts forward, which makes it impossible to rigidly connect the air intake to the filter inlet air duct. Therefore, a seal is provided between the air intake and the inlet air duct of the filter, which ensures the tightness of the connection in the transport (lowered) position of the cabin. In some models of Kama trucks (for example, in KAMAZ-55111 dump trucks), the air intake has a small height and is installed directly on the filter, so they do not have a seal.

Air filter. KAMAZ vehicles, as well as most other domestic trucks, use a two-stage dry air filter. The first stage is centrifugal; dust is separated due to centrifugal forces that arise when the drum rotates (it is driven into rotation by the incoming air flow). Dust is collected in a hopper and removed through a small cross-section pipeline connected to the exhaust pipe - a vacuum of air (exhaust gases) is created in the exhaust pipe, due to which dust is sucked out of the filter. The second stage of the filter is a standard paper filter element, which can be quickly replaced when dirty.

Engine air intake duct. This is a system of air ducts that supply purified air to each of the cylinders. Typically, air ducts are located in the camber of the engine, on the side of the cylinders.

We’ll tell you separately about the air intakes that are used in KAMAZ vehicles.

Purpose and role of the air intake in the KAMAZ engine power system

As the name suggests, the air intake is responsible for extracting air from the atmosphere and supplying it to the air filter. However, the question arises here: why does a truck need a special air intake, if many cars, especially cars, work normally without this part? In fact, the air intake on KAMAZ vehicles plays an important role, and its necessity is determined by the design and operation features of the vehicle.

Typically, trucks are operated in difficult conditions - with heavy dust, mud, etc. Therefore, air intake for the engine must be done so that as little dust, dirt, insects, etc. as possible enter the filter and the power system. The air intake solves exactly this problem; it is usually located in the “cleanest” place - behind the cabin. Here, due to turbulence, the air contains less contaminants, and its quantity is sufficient for normal engine operation, including with a turbocharger.

Thanks to the presence of an air intake, the issue of the location of the filter and other components supplying the engine with air is also easily resolved - they can be mounted in any convenient place, and this does not impair their performance. So the presence of an air intake solves several problems of a different nature at once; the normal operation of the engine, as well as the condition of the filter and other parts of the power system, depend on it.

Types, design and operation of KAMAZ air intakes

Today there are three main types of KAMAZ air intakes:

Classic round air intakes mounted on the cabin;

. Modern air intakes of rectangular section (“flat”), mounted on the cabin;

. Short air intakes mounted directly on the filter.

Air intakes of all types are very simply designed and contain a minimum of parts.

Round air intakes consist of a pipe (air duct), in the upper part of which the air intake itself is installed - a cap or visor that increases the area of the inlet opening. The inlet hole must be covered with a mesh, which prevents large contaminants, stones, insects, leaves, etc. from entering the system.

In addition to the usual ones, there are also rotating cylindrical air intakes, made in the form of a drum mounted on the air duct. Rotating, such a drum acts as a centrifugal filter, discarding more or less large contaminants, preventing them from getting stuck in the mesh filter. The rotation of the drum is ensured by the incoming air flow.

However, today more and more wide application find modern flat air intakes that take up minimal space behind the cab, while still providing effective selection air from the atmosphere. There are two types of such air intakes:

For horizontal installation;

. For installation in a vertical position.

The difference between these parts lies in the position of the inlet, which is located so that after installing the air intake it “looks” to the side, that is, air is taken from the right or left side of the cabin. Regardless of the location, the inlet is covered with a protective grille (plastic or metal) or blinds.

Today, air intakes made of plastic are increasingly used - they are extremely low cost, reliable and efficient. And in case of breakdown quickly and without extra costs may be replaced.

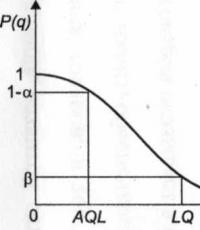

The main parameters characterizing the engine as an aircraft power plant are the thrust it develops and specific fuel consumption. These parameters are determined based on the characteristics of intra-engine processes, which in the case of a turbojet engine depend mainly on the operation of the compressor and turbine. However, with an increase in flight speed, other components and assemblies begin to have an increasing influence on the operation of the engine. This primarily applies to the air duct, the shape of which depends not only on the design and purpose of the engine, but also on its location on the airframe. As the flight speed increases, the pressure loss in the air channel increases, resulting in a decrease in engine thrust and an increase in specific fuel consumption.

Rice. 1

Consequently, the characteristics that determine the aircraft are propulsion system as a whole, and not just the engine. This statement primarily applies to supersonic aircraft, since the difference between the corresponding characteristics of the propulsion system and the engine increases with increasing flight speed. Therefore, for the propulsion system, the concept of “effective thrust” is introduced, which is understood as the resultant forces acting on the external and internal surfaces of the engine. The nature and magnitude of the forces created by internal pressure and the friction forces caused by the viscosity of the working fluid are determined by the processes occurring inside the engine. The forces acting on the external surfaces are determined by the nature of the external flow around the engine and depend on the location and method of installing the engine on the glider, as well as on the flight speed. The air intake and air duct, which usually form part of the airframe, more than any other element, influence the force of thrust created by the propulsion system. They provide the supply of air necessary for normal engine operation, in the required quantity and at a certain speed and pressure. At low flight speeds, air compression in front of the combustion chamber occurs mainly in the compressor. With an increase in flight speed, and especially after reaching supersonic speeds, it became possible to use the kinetic energy of the flow to increase the air pressure supplied to the engine. At such speeds, the role of the air intake increases significantly, since the use of the kinetic energy of the oncoming air flow leads to a decrease in energy consumption to drive the compressor. Such an input device is actually a pre-turbineless compressor.

In transonic aircraft, an air intake of constant geometry with a rounded leading edge performs its function quite well. Careful profiling of the air intake ensures low losses, as well as a uniform flow velocity field in front of the compressor. However, at supersonic speed, an unattached direct shock wave is formed in front of such an air intake at a distance of the thickness of the shock layer, after which the speed decreases to a subsonic value. Such a jump is accompanied by large wave resistance, so air intakes of constant geometry with a rounded leading edge can only be used up to M ‹ 1.14-1.2.

For supersonic aircraft, it was necessary to develop air intakes of a different shape and a different operating principle. Due to the wide range of operating speeds of these aircraft, their air intakes and air ducts must perform equally well in different conditions, providing both simple air supply during takeoff and optimal shock control during maximum speed flight. Thus, the design of the air intake depends on the speed of flight and the location of the engine on the airframe, as well as on the shape and principle of operation of the engine inlet device.

Air intakes have been used in supersonic aircraft built to date:

- 1) central (frontal), i.e. located along the axis of symmetry of the aircraft (or the axis of the nacelle), or lateral (on the sides of the fuselage);

- 2) unregulated or regulated, i.e. air intakes, the internal geometry of which is constant or can change depending on flight conditions;

- 3) with external, internal or combined compression, i.e. air intakes in which air compression by converting the kinetic energy of the flow into static pressure occurs, respectively, in front of the air intake or in the air duct;

- 4) flat or three-dimensional, i.e. air intakes, the cross-sectional shape of which is close to rectangular or round (semicircular, elliptical, etc.).

From these data it follows that 33 aircraft have a frontal air intake (including 13 unregulated), and 52 have a side air intake (including 17 unregulated). Three planes with rocket engine, naturally, did not have an air intake. In 21 cases, frontal air intakes are located in the fuselage and in 12 cases in nacelles. Among the fuselage air intakes, in 18 cases they are located in the forward part of the fuselage, and in the remaining 3 they are used above the fuselage (in the YF-107A aircraft) or under the fuselage (in the Griffon and F-16 aircraft). Side air intakes are usually located in front of the leading edge of the wing in its plane, above the wing or below it, depending on the adopted aerodynamic design of the aircraft. The first option is typical for mid-wing aircraft, and the second and third are typical for low-wing and high-wing aircraft, respectively.

The central air intakes in the fuselage or in individual nacelles are made almost exclusively round in cross-sectional shape, and only in rare cases is an oval shape used (F-100, Durendal, etc.) The advantage of engine air intakes located in nacelles is their direct connection with compressor, due to which they have low mass, low pressure losses and a uniform flow velocity field. In cruising flight at supersonic speeds, round air intakes are also characterized by a constant system of shock waves corresponding to the design operating conditions.

The disadvantages of round air intakes include a decrease in their efficiency with increasing angle of attack, due to changes in the shock wave system. In the case of central fuselage air intakes, the air channel turns out to be long and complex in shape, which requires a significant volume of the fuselage and makes it difficult to accommodate fuel, equipment, etc. In addition, such an air intake eliminates the possibility of using a large-diameter radar antenna, the size of which is limited by the dimensions of the central body located inside the input device.

The disadvantage of the dorsal and ventral air intakes is that their effectiveness is reduced at high angles of attack (positive or negative, respectively) due to the fact that the air intake is obscured by the fuselage and wing.

Side air intakes have a significantly greater variety of cross-sectional shapes. In the early days of supersonic aircraft, semi-elliptical, semi-circular, or quarter-circle air intakes were commonly used. Recently, flat rectangular side air intakes with rounded corners have been almost universally used. The rejection of semicircular air intakes is explained by the desire not to distort the profile of the wing roots and the flat shape of the supporting fuselage. Placing air intakes on the sides of the fuselage allows not only to significantly shorten the air channels, but also to occupy the entire forward part of the fuselage with equipment, including radar equipment. The flat side air intakes work very effectively across the entire range of operating speeds and angles of attack.

The main disadvantages of the side air intakes are the shading of one of them by the fuselage during gliding maneuvers at supersonic flight speeds and the influence on their operation of the boundary layer, which is the main source of unevenness of the velocity field in the air intake and air channel. The boundary layer arises as a result of viscous friction of the air flow on the streamlined surfaces of the aircraft, and the flow velocity near the skin drops sharply to zero. In supersonic flow, shock waves, interacting with the boundary layer, cause local separation of the flow from the streamlined surface with a sharp increase in the thickness of the boundary layer 1., etc., where 1. The thickness of the boundary layer depends on the flight speed, the air viscosity coefficient, and also on the length of the streamlined surface area. It is assumed that the thickness of the boundary layer is 1% of the length of the streamlined section at supersonic flight speed and increases with decreasing speed.

The unevenness of the velocity distribution due to the boundary layer increases so significantly that, for example, in an aircraft with air intakes directly adjacent to the fuselage skin, at a flight speed of M = 2.5, thrust decreases by ~ 45%, and specific fuel consumption increases by ~ 15%.

Rice. 2

a-lateral air intake of the F-4 aircraft (the movable front and fixed ones are visible - with the boundary layer removal system - part of the wedge); b-side air intake of the Mirage III aircraft (the gap for removing the boundary layer from the fuselage surface and the shock generator in the form of a semi-cone are visible); c-ventral air intake of an F-16 aircraft.

A similar problem exists for front air intakes equipped with cones or wedges, as well as for air intakes with internal or combined compression. Air intake or engine surge caused by flow separation can lead to an accident. To eliminate this undesirable and dangerous phenomenon, devices are used to remove the boundary layer from the surface of the fuselage (wing) in front of the side, under- or dorsal air intake, as well as holes for suction of the boundary layer from the surface of the cone or wedge, which favors continuous flow. In this case, the boundary layer air is diverted into the external flow or used to cool the engine. turbojet engine air intake generator

Thus, the problem of operating the air intake of an aircraft with M ‹ 1.1-1.2 is very complex, and therefore the inlet device must be designed somewhat differently than in a subsonic aircraft.

In the range of low supersonic speeds, unregulated air intakes are still applicable, made with sharpened inlet edges, at which a local attached direct shock wave occurs.

The flow velocity behind such a jump decreases to subsonic, but it is still so high that it is necessary to further slow down the flow to the speed required by the compressor. This happens in an expanding diffuser. The use of sharp inlet edges prevents the formation of a thick boundary layer in the air intake and the subsequent separation of this layer, which impairs engine performance. Behind a local attached shock wave, the air velocity decreases to a subsonic value as sharply as behind an unattached bow shock, however, due to its locality, most of the kinetic energy is converted into static pressure (the rest is converted into thermal energy). However, with an increase in flight speed, the intensity of the shock and, accordingly, losses in the process of dynamic compression increase, as a result of which the thrust of the propulsion system decreases. Therefore, air intakes of this type are used in aircraft with a maximum speed not exceeding M = 1.5. At higher speeds, good efficiency of dynamic compression on the traveling flow can be achieved only in a system of oblique shock waves, which are characterized by lower intensity, i.e. less speed drop and less pressure loss. The flow velocity behind the oblique shock still remains supersonic, and if it corresponds to a Mach number not exceeding 1.5-1.7, then further deceleration of the flow can occur in the forward shock. The losses in such a weak shock are small, and the subsonic speed behind it is already acceptable for the air channel. The two-hop air intake operates effectively up to a flight speed of M = 2.2. With a further increase in the free-stream velocity, the Mach number behind the oblique shock also increases. If it exceeds 1.5-1.7, then the air flow should be further compressed in another oblique shock so that its speed before the closing direct shock has an acceptable value. An air intake with such a jump system is called three-shock and can be used up to M ~ 3.

The required jump system can be created by extending a sharp-edged element forward from the air intake (regardless of the compression principle used) or by using an air intake with sharp inlet edges and a suitably profiled diffuser (in inlet devices with internal or combined compression).

The structural elements inside the air intake used to create oblique shock waves are called shock generators. In practice, generators in the form of cones, half-cones, quarter-cones and wedges have been used. At their apexes during supersonic flight an attached shock is formed with an inclination angle depending both on the angle at the apex of the body and on the Mach number. Since in an oblique shock the change in flow parameters, as mentioned above, occurs less sharply than in a direct shock, the losses are significantly smaller, and thus the static pressure created is higher. The higher the flight speed and the number of oblique shock waves in which energy conversion occurs, the greater the static pressure of the stagnated flow.

In practice, two-, three-, and even four-hop systems are used. The second and subsequent oblique shocks can be created by a generator with a broken generatrix or as a result of the reflection of disturbance waves from the internal walls of the diffuser. The first method of creating surges is typical for air intakes with external compression, and the second - with combined compression.

Rice. 3.

a - “Super-Mister” V.4; 6-F-100; e-F-104; g-F.D.l; d-F-8; e-B-58.

Rice. 4

In air intakes with internal compression, surges are induced within the non-axisymmetric air channel due to the corresponding profile of the cross sections of the diffuser.

The methods described above for creating shock waves differ from each other in the location of shock formation relative to the plane of the entrance to the air intake. A common feature They are a multi-stage process of flow braking, which ensures maximum use of dynamic compression, minimal losses and uniform speed distribution.

The first supersonic aircraft with air intakes equipped with oblique shock generators used external compression input devices. Compared to others, they are quite easy to adjust and are lightweight. The generator is placed relative to the entrance to the air intake in such a way that the primary shock generated by it touches the entrance edge of the air intake under design flight conditions, which allows for maximum air capture, minimal losses during the compression process and minimal internal resistance of the inlet device.

However, significant disadvantages of input devices of this type compared to others are the large (highest) external resistance associated with a change in the direction of flow, as well as the smallest increase in static pressure and a large frontal area due to the fact that a surge generator must be placed inside the air intake. Theoretically, it is most rational to use input devices with internal compression, which are the most efficient and have minimal external resistance. However, such input devices have not yet found practical application due to the complexity of the structure of the profiled air channel and the need to smoothly change its internal geometry in accordance with changing flight conditions and engine operation. Currently, input devices with combined compression are increasingly used, which, with a relatively simple design, are quite highly efficient.

The presented examples of the geometry and design of air intakes indicate the possibility of an individual approach to the problem of designing an air intake, taking into account the changing conditions of its operation. Shown in Fig. 1.45 and 1.46 air intakes are fundamentally different in shape and appearance, but they are similar in nature of work at a certain speed. Differences in detail are usually due to accepted theoretical assumptions, experimental results and the tastes of designers.

For example, the British experimental aircraft F.D.2, which set a world speed record (1822 km/h) in 1956, had a very specific air intake. Its upper entrance edge is pointed and moved forward relative to the rounded lower edge. On the one hand, this leads to the appearance of an attached oblique shock at the upper edge, which passes at a certain distance in front of the lower edge, preventing an unattached direct shock from arising near it. On the other hand, moving the upper edge forward allows you to increase the frontal cross-section of the air intake in flights at high angles of attack, when the flight speed is low and the required air flow in the engine is high.

In addition, additional air supply or exhaust devices included in the air intake system have become widespread. Such devices include inlet (take-off) and bypass flaps, which are usually located either near the control element (cone, ramp, wedge) or along the length of the air channel and open or close depending on the air flow required by the engine. In Fig. Figure 1.47 shows the positions of the air intake elements of an F-14 aircraft in various flight modes.

During takeoff and flight at low speeds, the front and rear parts of the movable air intake ramp are raised, and the takeoff and bypass flap is open, which ensures that the required amount of air reaches the engine, despite the low speed of the oncoming air flow. With an increase in flight speed and air pressure at the compressor inlet, the direction of the air flow flowing through the take-off door changes to the opposite, and excess air from the air channel is released into the atmosphere. When flying at transonic speed, the throughput of the flap turns out to be insufficient, and to limit the flow of air into the compressor, the rear part of the ramp is deflected downwards, as a result of which the flow area of the air intake decreases, and the dimensions of the air exhaust channel increase. When flying at high supersonic speeds, the front and rear sections of the ramp are further deflected downward, ensuring that the optimum amount of air enters the engine. The gap between the front and rear of the ramp is used to drain the boundary layer.

It follows from the above discussion that supersonic air intakes with an oblique shock generator must be profiled such that at the design airspeed the primary shock contacts the leading edge. This position of the jump ensures the greatest efficiency of the input device, since in this case the air flow is maximum, losses in the compression process and input resistance are minimal, and the engine operates most stably. Obviously, such conditions exist only at a certain Mach number. This means that a given Mach number corresponds to a certain position of the shock generator relative to the entrance edge of the air intake, and in other operating modes the characteristics of the air intake deteriorate. Thus, in a wide range of supersonic free-stream speeds, satisfactory operating characteristics of an engine with an unregulated air intake cannot be ensured.

This drawback is a consequence of the discrepancy between the constant geometry of the air intake, calculated for certain flow conditions, and the optimal parameters of the internal and external flows under non-design conditions. This disadvantage can be eliminated partially or completely by changing the geometry of the air intake (inlet, critical and/or outlet sections) in accordance with changing flight speed and altitude. This is typically accomplished by smooth, automatic movement of the control element, which ensures the required air flow with low external resistance over a wide range of flight speeds, matching the inlet capacity to the compressor performance, and matching the surge system to the air intake configuration. This also eliminates the possibility of an unattached direct bow shock - the main reason for the unsatisfactory performance of the air intake and the air channel as a whole.

In conclusion, it should be noted that the location of engines and air intakes on an aircraft, as well as the choice of the type of input device, are the subject of complex studies that take into account not only the requirements for ensuring the best conditions operation of the propulsion system, but also the characteristics of the aircraft as a whole.

With the massive advent of jet aircraft engines in the 40s, air intakes began to play a vital role in aircraft design.

They can be compared to human lungs. Just as oxygen in the lungs serves to provide life support for all living matter in the human body, so the air from the air intakes serves to provide life support to the “heart” of the aircraft - its power plant(engines).

Air-jet engines run on fuel (today it is mainly liquefied gas). In order for the gas to ignite internally, it must be oxidized (although “evaporate” is a better word). The oxidizing agent in this case is oxygen, the amount of which in the air is 23%. It turns out that only a quarter of the air is suitable for engine operation, but where does the rest of the air go? The remaining 77% of the air is used to cool the combustion chamber, as well as the nozzle, from which hot combustion products escape into the atmosphere. Experts call this air secondary or ventilation. It helps protect the chamber and turbine walls from damage: cracks, charring and, in extreme cases, melting.

The air intake, then a special compressor used to compress the air, as well as the combustion chamber are unified system in any modern jet engine. They interact as follows: first, the air enters the air intake, where it is compressed and heated to a temperature of 100 to 200 °C (this temperature ensures sufficient evaporation of the fuel and its almost complete combustion), then the air enters the compressor, where it undergoes another stage of compression and heating , and finally, in its finished form, it ends up in the combustion chamber along with the gas, where a powerful electric spark ignites a mixture of oxygen and gas. The speed at which air enters the combustion chamber is 120 - 170 m/sec. This flow is 3 to 5 times stronger than a gust of wind in the most powerful hurricane, capable of destroying buildings.

In air-breathing engines of modern supersonic aircraft (from 1400 km/h and more), the compressor has lost its relevance, since when high speed The air intake itself heats and compresses the air quite effectively.

Modern air intakes consist of three layers: two metal layers and, located between them, a glass-woven honeycomb core. Most likely, the choice of aircraft designers fell on this design for the following reasons: firstly, the use of honeycomb core provides greater structural strength, although at first glance it may seem that this is not the case; secondly, honeycomb core is a good sound and heat insulator. A fan is installed in the recess in the foreground, which evenly distributes the air flow.

Air intakes vary in size, shape, and location on the body. There is no exact data on their sizes, but we can say that on average the air intakes of modern aircraft reach at least 1 meter in diameter, but there are many exceptions, this applies to light military aircraft with small dimensions. On large transport and passenger aircraft their diameter is more than two meters.

Traditionally, round and square (or rectangular) air intakes are installed on airplanes, however, there are exceptions in the form of ovals and arcs.

If the shape of the air intakes is selected for each aircraft separately based on the performance characteristics of that particular aircraft, then their location must be based on strict aircraft design rules.

There are three types of air intakes based on their location on the aircraft: frontal, side and underwing (or ventral). True, in fact today there are only two species left. Frontal air intakes have become a thing of history (F-86 Saber, Su-17 or MiG-21).

Aircraft designers considered the main advantage of frontal air intakes to be a uniform air flow rate, since, unlike all other types of air intakes, they are the first to encounter the air flow. In other cases, either the nose of the fuselage or the wings are the first to encounter the air flow.

The most common type of air intakes in modern aviation are side ones. The reason lies in the fact that the most important detail of any modern combat aircraft became radar equipment. It is located in the forward part of the fuselage, so when airplanes had frontal air intakes for reconnaissance equipment, there was practically no space left.

The last, less common type of air intakes is underwing (ventral) intakes. The name itself speaks about their location. They are no worse than the side ones and can also be installed on both twin-engine and four-engine aircraft, however, experts in the field of aircraft construction note one serious drawback. Underwing air intakes are ineffective at large negative angles of attack, that is, when the aircraft is not in level flight, but is performing maneuvers with a sharp climb or stall.

It is also worth noting that air intakes are not always a static hole into which air constantly flows, regardless of whether the situation requires it or not. Many modern aircraft (and almost all of them), such as Su-33, Su-35, MiG-29 fighters, T-4 missile-carrying bomber and others, are equipped with adjustable (automatic) air intakes, which allows you to control the power of the air flow and adapt air intake towards its direction. In case automatic control air intakes will fail, manual control is provided.

Literature

- 1. Aviation equipment / ed. Yu. P. Dobrolensky. - M.: Military Publishing House, 1989. - 248 p. -- ISBN 5-203-00138-3

- 2. L.L. Selyakov "THE THORNY PATH TO NOWHERE. Notes of an aircraft designer."

- 3. S.M. Eger, V.F. Mishin, N.K. Liseytsev. Aircraft design. (M.: Mashinostroenie, 1983)

- 4. S.M. Egera, I.A. Shatalov "Fundamentals of aviation technology."

IEDs of Tu-160 bomber engines.

Today we'll talk about air intakes. This topic is quite complex (like many things in aviation). I will try, as always, to simplify it more for general acquaintance... We'll see what comes of it :-)...

About what happened...

The beginning of a fine summer day in 1988 was no different from many of the same weekday days in the 164th Orap (Brzeg, Poland). It was a daytime flight shift. The weather scout has already returned, and the flights of all squadrons have begun according to the planned flight tables. The afterburner roar of taking off aircraft excited the surroundings, and even in the hangar parking lot of the TECH, its impressive power could be clearly felt.

I was then acting as head of the engine regulations group. Immediately after the general formation, the head of the TECh rushed to me and took me aside for a conversation. The news was, to put it mildly, unpleasant. One of the MiG-25s got into a difficult situation while accelerating at supersonic speed.

First, the pilot felt strange shocks, then the afterburner of the right engine went out and almost immediately after that it switched off automatically. The launch attempt was unsuccessful, the pilot stopped the mission and, continuing the flight on one engine, returned to the airfield. The landing was completed successfully, without any problems, however, there was a serious flight accident.

We, the engine engineers, together with the AO specialists, after transporting the aircraft to the TEC, began searching for the cause of what happened. At preliminary inspection it was discovered that the entire afterburner within the visibility of its elements was wet from fuel. does not evaporate so quickly, especially the type (quite heavy) that was then used on the MiG-25 (T-6).

MiG-25RB aircraft.

However, this does not happen during a normal engine shutdown, because it is performed by stopping the supply of fuel to the combustion chamber (throttle throttle at STOP), and the remaining fuel from the fuel manifolds, after the cessation of combustion and atomization, is drained into the drain tank.

This means that turning off the afterburner and stopping the engine probably occurred suddenly due to the extinguishing of the flame in the FCS and OKS, and the fuel continued to flow and be sprayed by the injectors for some time until the throttle was set to “Stop”. And the reason for the extinction was apparently problems with air flow.

Literally immediately after the start of the checks, a failure of the right air intake control system was detected . As a result, during acceleration at an already sufficiently high supersonic speed, a air intake surge, which caused the extinguishing of both combustion chambers (OKS and FKS) and, as a consequence, the engine stopping.

A fairly lengthy description of the circumstances surrounding the flight accident was required because its cause directly relates to the topic of today’s article. In this case air intake– this is not just a pipe passing air. This is a serious, working element of the power plant of an aircraft with a turbojet engine (D, F), when creating which must be observed the whole complex norms and rules. Without them, its correct operation and, ultimately, the efficient and safe operation of the entire propulsion system is impossible. Incorrect operation of the air intake (IA) of a turbojet engine can cause a serious and even, in special cases, severe flight accident.

————————

The name itself, however, does not give any hints in this regard. Word "air intake" means a special structural unit that, using high-speed pressure, “takes air” from the atmosphere and supplies it to specific units aircraft. By the way, not only aircraft, but also, for example, various, especially quite high-speed, cars.

The purpose of air intake may be different. Basically, they can be divided into two groups that differ significantly from each other.

First. Outside air on fast moving vehicles vehicles(primarily on aircraft), convenient for cooling certain components, devices, units and their structural parts or technical special fluids (working fluids) used for the operation of systems that heat up during operation. For reasons of streamlining, such systems and assemblies are mostly located inside (and even deep inside) the structure of the aircraft.

They exist to supply air to them. special air intakes, combined, if necessary, with air ducts that form and direct an air stream to the desired location. In this case, cooling fins, special radiators, both air and liquid, or simply parts and housings of units can be subjected to cooling for the purpose of cooling.

There are enough such structural units on every aircraft. And, in general, they are not anything particularly complicated. Of course, all air channels must be correctly profiled, mainly in order to maintain a minimum of drag and supply a sufficient amount of air for blowing.

Air intakes for cooling equipment on the Su-24MR aircraft.

However, incorrect operation of such air intakes, as a rule, does not lead to immediate disruption of the operation of ventilated aircraft components and, even more so, to any serious or fatal consequences for the aircraft.

An example is the air intakes for cooling units of the Su-24M aircraft.

Second. But poorly performing air intakes belonging to the second group may well be the reason for this. This air intakes air-jet engines. The air that they pass through is supplied to the input of these engines and serves as a working fluid for them (further turning into gas).

The characteristics and efficiency of the engine (including thrust and specific fuel consumption), and therefore, ultimately, the entire aircraft, depend on the parameters and quantity of incoming air, the quality and condition of the air flow. After all, the engine, as you know, is its heart. The condition of this heart is largely determined by the correct operation of the most important unit of the power plant - the air intake, which is otherwise (and deservedly) called input device gas turbine engine(VU GTD).

——————————————

The importance of proper operation of the air intake directly depends on the flight speed. The higher the speed capabilities of the aircraft, the more complex the design of the turbojet engine and the higher the requirements for it.

When the engine is operating under starting conditions, air enters the air intake mainly due to the vacuum created by the gas turbine engine compressor at the inlet. In this case, the main task of the air intake is to direct the air flow with the least loss.

And with increasing speed, when flying at high subsonic and, especially, supersonic speeds, two more tasks are added to this task, and both of them are main. It is necessary to reduce the flow speed to subsonic, and at the same time effectively use velocity pressure to increase the static air pressure before entering the engine.

Exactly this usage consists of converting the kinetic energy of the oncoming flow (velocity pressure) during its braking into potential energy of air pressure. Quite simply, this can be said as follows.

Since the total pressure of the flow (according to Bernoulli’s law) is a constant value and equal to the sum of static and dynamic pressure (we can ignore the weight pressure in our case), then as the dynamic pressure drops, the static pressure increases. That is, the inhibited flow has a higher static pressure, which is the basis of the work air intake.

That is, the VZ essentially works like a compressor. And the higher the speed, the more impressive this work is. At speeds of 2.-2.5 M, the degree of pressure increase in the air intake can be 8-12 units. And at high supersonic (and hypersonic) speeds, the operation of the air intake is so efficient that the need for a compressor virtually disappears. There is even such a thing as “ compressor degeneration"at high supersonic speed. This is the same process when a turbojet engine gradually turns into a ramjet.

It should be noted that in real air intakes with such dynamic compression, not all the kinetic energy of the flow is used to increase pressure. There are inevitably losses (so-called total pressure losses), which depend on many factors and differ for different air intakes.

Types of modern input devices.

In relation to the speed (maximum) of the aircraft on which they are used, VZs can be subsonic, transonic and supersonic.

Subsonic…

Currently, these are most often the input devices of high-bypass ratio turbofan engines. They are typical for modern subsonic passenger or transport aircraft. Such engines are usually located in separate engine nacelles, and are air intakes They are quite simple in design, but not so simple in terms of the requirements placed on them and, accordingly, their implementation.

As a rule, they are calculated for cruising flight speeds of about 0.75...0.85M. They must have a relatively low mass, provided that the required air flow is ensured. A very important requirement for them is to ensure low energy losses of the air flow (internal losses), which they direct into the engine through their channel, as well as losses to overcome external resistance (external losses).

Scheme of flow and changes in flow parameters in a subsonic gas turbine engine.

This is ensured by correct profiling of the internal channel and external contours, which reduces drag and improves flow. In addition, the leading edges of the inlet device most often have a fairly thick profile, taking the shape in the longitudinal (meridional) section of the channel.

This allows for continuous flow around surfaces, which minimizes losses and, in addition, provides another useful effect. When flowing around a thick entrance edge, an aerodynamic force similar to lift arises.

And its horizontal projection is directed along the flight and is a kind of additive to thrust. This force is called “suction”, and it very significantly compensates for the external resistance of the air intake.

Flow around a subsonic air intake. Action of suction force.

The conversion of dynamic pressure into static pressure in this type of air intake occurs as follows. The design of the channel is calculated so that in its inlet section the flow velocity is less than the flight speed. As a result, the flow before entering the air intake has the shape of a diffuser (“diverges” to the sides), which inevitably entails braking and an increase in pressure (the aforementioned Bernoulli’s law).

That is, compression from the high-velocity pressure mainly occurs even before entering the air intake (the so-called external compression). Then it continues on the first section of the channel, which is also profiled in the form of a diffuser. And in front of it, the channel most often still has a small confusive section (that is, a tapering section). This is done in order to equalize the flow and velocity field.

Subsonic air intake with make-up flaps and a beveled entrance plane.

Entry plane air intake often sloping. This is done to ensure efficient operation of the air intake (and engine) at high angles of attack, when the inlet is obscured by the lower part of the engine nacelle housing.

In design input device of this type, for some engines, so-called . When the engine operates at elevated speeds under starting conditions (that is, there is no speed pressure or is quite low), it is not always possible to provide the required air flow.

Preliminary external compression in such modes is practically absent, and the inlet section of the air intake simply cannot pass all the required air, since its dimensions do not allow it.

Airplane Yak-38. Takeoff mode - make-up doors are open.

Flaps for additional air supply in starting conditions (taxiing). Airplane Tu-154B-1 engine NK-8-2U).

Therefore, additional windows can be made on the air intake shell, which open at the desired mode (usually due to vacuum in the air intake channel) and close after gaining speed. An example is the Tu-154B-1 aircraft. The video clearly shows the opening of the feed flaps on the left engine.

Transonic.

Such input devices radical In general, there are few structural differences from subsonic ones. However, their flow conditions are already more stringent, because they are used in aircraft power plants with maximum flight speeds of up to 1.6...1.7M. Up to these speeds, the use of an air intake with a constant flow path geometry does not yet lead to a large increase in losses as a result of dynamic compression.

Such air intakes have sharper edges compared to subsonic air intakes to reduce wave drag, which, as is known, manifests itself in the transonic and supersonic flow regions. To reduce losses due to stall when flowing around sharp edges and to ensure air flow at low speeds and under starting conditions, additional make-up windows can also be used on these air intakes.

Subsonic and transonic air intake. Position of the direct shock wave.

In front of such an air intake during supersonic flight, a direct shock wave(I wrote about the formation of shock waves). For sharp edges it is attached. When passing through it, the pressure in the flow increases (external compression). A further increase in pressure occurs in a diffuser-type channel.

To reduce the flow velocity before the shock wave input device advantageous to be located in the so-called slow flow zone, which is formed when the flow flows around the structural elements located in front of the air intake (adjacent air intakes - more about them below).

Transonic air intake of the Su-24M. The plane of the PS drainage device and the perforation of the PS suction device are visible.

These are, for example, side (Su-24M, F-5)) or ventral entrance devices (F-16). Structurally, they are usually moved away from the fuselage to form a kind of slot channel 50–100 mm wide. It is needed so that the boundary layer growing on the front of the fuselage surface does not fall into the air intake channel and disturb the uniformity of the flow, increasing losses. It seems to “merge” further into the stream.

Su-24M bomber during taxiing. The make-up valves are open.

Ventral transonic air intake of an F-16 aircraft.

A device for draining the boundary layer on the air intake of an F-4 "Fantom" aircraft.

Supersonic.

The main difficulties begin for input devices when using higher maximum speeds flight - 2.0...3.0M or more. At such speeds transonic air intake cannot be used due to the large increase in the intensity of the direct attached shock and, accordingly, the increase in total pressure losses, which negatively affects the engine parameters (in particular, thrust).

High compression efficiency here is achieved using supersonic input devices (SVU). They are more complex in design and are used to increase pressure. shock system.

To control the process of flow deceleration (and therefore increase the pressure in it), the so-called so-called braking surface , having a specific profile. This surface, when interacting with a supersonic flow (high-speed pressure), creates conditions for the formation of shock waves.

As a rule, there are several of them, that is, a system of shocks is created, including two, three (or even four) oblique and one direct shock (the so-called head wave), which is trailing. When passing through oblique shocks, the decrease in speed and loss of total pressure is less than when passing through straight shocks, the change in parameters is less sharp, and the final static pressure is higher due to lower losses.

In general, the more oblique shocks, the less pressure loss in the flow. However, their number is determined by the design of the air intake, designed for certain maximum speeds.

Passing through such a system, the flow reduces its speed to approximately 1.5...1.7 M, that is, to the level of transonic air intakes. After this, it can pass through a direct shock with relatively small losses, which is what happens, and the flow becomes subsonic, acquiring a certain amount of pressure, and then passes through a narrowing channel into its smallest section, called the “throat”.

The braking surface can have different shapes, but most often it is in the form of a wedge or cone (depending on the shape of the air intake). A wedge (cone) usually has several surfaces (or steps) articulated with each other. Oblique shock waves are formed at the junction points (corners).

Their inclination depends on the Mach number of the flight and the inclination angles of the individual stages. These angles are selected to create flow conditions that are closest to optimal in the design mode.

Depending on the location of the braking surface relative to the air intake body (its shell), as well as its configuration, the shock waves can be located differently relative to the entry plane air intake.

Types of VCA: a) external compression: b) mixed compression: c) internal compression.

This, in turn, determines the type of braking process and, accordingly, the type of the supersonic input device itself. First type– VCA with external compression. All of his oblique shocks are located in front of the plane of the entrance to the air intake (that is, outside), and the throat is located in close proximity to it.

Second type – VCA with mixed compression. Here, part of the oblique shocks is located outside, up to the entrance plane, and part inside, that is, behind it. The throat is moved further away from the entrance edges, and the channel from the entrance to the throat is narrowed.

Third type– VCA internal compression. In it, all shock waves are located inside the air channel behind the inlet plane.

In practice, VCAs with external compression are mainly used. The use of two other types, theoretically more effective for compressing flow at high supersonic speeds, in practice encounters various technical difficulties.

There is also a division of air intakes into types according to design characteristics:

According to the shape of the inlet section.

These are the so-called flat and spatial (usually axisymmetric).

Flat intakes (sometimes they are box-shaped or scoop-shaped) have an inlet section in the form of a rectangle, sometimes with roundings at the corner points. The channel itself from the rectangular entrance gradually changes its cross-section to round before entering the engine.

Controllable air intake of an early series Su-24 aircraft. The hinge for turning the vertical panel is visible. Perforations for boundary layer suction are also visible.

The braking surface of a flat air intake is made in the form of a wedge with a special profile. If the air intake is controllable (more on this below), then the flat one has good opportunities for this, namely the possibility of a sufficiently large change in its geometry, allowing you to create a system of shock waves of varying intensity.

U axisymmetric air intake to create such a system, a cone is used, also profiled in a special way (stepped). The inlet cross-section of such an air intake is circular. The cone is the central body in the first section of the internal channel; then the channel also has a circular cross-section.

Frontal axisymmetric air intake with a conical adjustable braking surface, on the MiG-21-93 aircraft

There are also so-called sector air intakes, the inlet section of which is a part (sector) of a circle. And their braking surface is also a part (sector) of the cone. They are usually located on the sides of the fuselage according to the lateral principle (more on this below) and compete with them in terms of reducing total pressure losses. An example of such structures is air intakes Mirage series aircraft, bomber F-111, Tu-128 interceptor, experimental MiG-23PD.

Mirage 2000-5 aircraft with traditional sector IEDs.

For modern aircraft (fifth generation), spatial air intakes are designed with various shapes input section (for example, T-50; F-22 - parallelogram) with the so-called spatial compression. Here, not only braking surfaces, but also specially profiled shell edges participate in the creation of a whole complex of shock waves.

Tu-128 aircraft with sector IEDs (museum).

By location on the fuselage.

These are frontal and adjacent. Frontal air intakes are installed either in the forward part of the fuselage or in separate engine nacelles. Thus, they operate in an undisturbed air flow. They are most often axisymmetric in shape.

MiG-15 fighter with a typical frontal subsonic air intake.

Adjacent airborne objects are located (adjacent) near any part of the aircraft surface. As a result, the air flow entering them is already slowed down due to its flow around the aircraft elements located in front. This means that the size of the required pressure ratio is reduced, which makes it possible to simplify the design of the air intake.

However, in this case one has to deal with the growing boundary layer, which tends to get into the air intake from the same elements located in front (most often from the fuselage). Usually the boundary layer is simply “drained” through a channel formed when the air intake is located at a certain distance from the aircraft structure (50...100 mm - already mentioned above).

Device for draining the boundary layer Eurofighter Typhoon.

Nevertheless, a certain degree of unevenness of the flow at the entrance to the channel is still formed. And it cannot always be productively corrected due to the rather short length (according to the aircraft layout) of the air duct.

Adjacent air intakes There are lateral, ventral and underwing. The braking surface almost always takes the form of a stepped wedge (horizontal or vertical). The exception is the above-mentioned sector air intakes, in which the braking surface is the cone sector (Mirage aircraft).

MiG-31 fighter during taxiing. Adjacent air intakes. The open flaps of the shell are visible.

Some features of VCA with external compression.

The VCA is designed for certain flight Mach numbers, usually close to the maximum. Based on this, design parameters are selected for the design mode. These are the areas of the inlet, throat and outlet, the angles of the braking surface panels (cone surfaces), the locations of the kinks of these panels, the angles of the shell (in particular, the “undercut angle”).

Undercut angle in the front air intake. 1,2 - braking surface, 3 - edge of the shell, 4 - air intake body.

For the design mode, there are two schemes of oblique shock waves. In the first, oblique shock waves are focused on the leading edge of the shell. The direct shock (head wave) is located in the channel behind the throat. The flow is organized in such a way that it enters the channel at supersonic speed and can become subsonic only by passing through this shock.

The disadvantage of this scheme of input devices is the interaction of such a direct shock with the boundary layer near the channel walls. This leads to layer separation and pressure pulsations, as a result of which the outlet flow may not be sufficiently uniform and stationary. However, this type of air intake has less external resistance compared to the second type.

In the second scheme, the direct shock (head wave) is advanced in front of the entrance to the air intake, being partly in the internal flow (in front of the channel), partly in the external one, and has different intensities along its length. Before entering the internal channel, it represents an almost straight shock, which only slightly bifurcates near the braking surface, becoming λ-shaped. In the external flow, it bends to the side against the flight, turning into an oblique one.

VCA with defocusing oblique shocks (second scheme). The slit for draining the PS, the perforation for its suction, as well as the principle of forming the spreading resistance are shown.

To prevent the head wave from destroying the system of oblique shocks in the immediate vicinity of the entrance to air intake, these shocks are slightly shifted and slightly defocused in relation to the input edge of the shell (due to the choice of the angles of location of the panels (β) of the braking surface), that is, simply put, they do not all (three) converge at one point of this edge, but continue further into external flow.

In calculations, however, such a scheme can be replaced with a sufficient degree of accuracy by a simplified one, when it is assumed that the system of oblique shocks is focused on the leading edge and is closed by a direct shock, also located directly on the edge of the shell.

VCA with shocks focused on the shell (first scheme). β - angles of location of adjustable panels.

This shift and defocusing has become the reason for the second type of input devices being most often used in practice. The fact is that this arrangement of shocks significantly reduces the possibility of their destruction by the head wave, which can move during operation to the inlet and outlet along the channel when the air intake operates in various off-design modes.

That is, the stability of the air intake, and therefore the engine as a whole, increases. However, resistance input device there is more of the second type. This is due to the emergence of the so-called spreading resistance, which does not exist for the first type.

A little about spreading resistance.

IN air intake of the first type, the flow immediately enters at supersonic speed (as mentioned above). And in the second type, where the head wave is located almost at the entrance to the air intake, the flow enters the channel already subsonic. Due to the location of oblique shocks, the flow at the inlet, passing along the stagnation surface, is formed in such a way that its outer layers spread out to the sides without falling into the air intake channel.

That is, the actual entrance area becomes smaller than the constructive one (in the figure above F H< Fвх ) поэтому и действительный расход воздуха через air intake is also getting smaller. That is, part of the air, slowed down, which has already passed through oblique shocks, and therefore energy (of the engine) was spent on increasing the pressure, does not enter the engine itself and does not participate in the creation of thrust.

There is even such a parameter to characterize the operation of the air intake as air flow coefficient, equal to the ratio of actual flow to the maximum possible. If this coefficient is less than unity, then there is a spreading of the flow at the inlet, which causes spreading resistance.

In general, at the same time, at the same time, for the air intake, in addition to the spreading resistance, other types of external aerodynamic resistance are also considered, the reduction of which must be strived for. This is important because the so-called external resistance of the inlet device is a force directed against the flight, which means it reduces the effective thrust of the entire power plant, which, in fact, includes the air intake.

In addition to the aforementioned spreading resistance, the external resistance of the air intake also includes shell resistance and various bypass valves (if any) are the so-called excess pressure forces, as well as friction forces in the flow.

Additional losses during flow passage in the channel are associated with the viscosity of the gas, as well as with the configuration of the channel itself. The harmful influence is expressed in an increase in the thickness of the boundary layer and an increase in the probability of flow separation due to the rather complex shape of the braking surface.

The shape of the canal and the area of the throat are adjusted to suit the purpose. reduce harmful effects. The flow makes a fairly sharp turn when entering the internal channel. To avoid flow separation, the channel itself is first made confuser (narrowing) and after turning, diffuser (expansion).

The flow reaches its highest speed (subsonic) in the throat. From the point of view of suppressing separation, the most advantageous speed in the throat becomes . If the flow speed in the throat is equal to the speed of sound, then the throat is called optimal.

The harmful effects of viscosity (boundary layer) are overcome using various technical devices. These include: the use of perforations in areas of the braking surface for suction of the boundary layer or special cracks near the throat to drain it. These techniques make it possible to reduce the size of the emerging separation zones, thereby streamlining the flow at the exit from the air intake.

To activate the boundary layer, special turbulators installed behind the throat are also used. They create small vortices that help mix the boundary layer with the main flow and thereby speed up the process of equalizing the flow velocity field in the channel.

———————

Returning to the above two types of VCA with external compression, we can say that despite the greater external resistance and lower real throughput(flow coefficient less than unity) in design mode, air intakes with defocused oblique shocks are generally more preferable to use than the VZ of the first scheme.

This is due to the fact that defocusing allows you to significantly increase stock of stable work air intake, which is quite important for safe operation in various operating modes, even with a slight decrease in efficiency.

During flight, the speed, altitude, temperature and density of the air and, of course, the operating mode of the engine itself, to which the air intake supplies air, change. Sometimes this air is needed a lot, sometimes not enough, and this (at a constant flight speed) will certainly affect the change in operating mode input device.

With a constant flight Mach number (for example, equal to the design one) and a change in the engine operating mode, three types of air intake operating modes can be distinguished.

The first mode is supercritical . In this case, there is a supersonic flow zone behind the throat. When switching to higher modes, the engine increases speed and needs a lot of air. It is clear that it intensively takes air from the air intake. In this case, the back pressure, which always exists in stationary mode at the end of the air intake channel (repressed air with already increased pressure, ready to enter), decreases.

Scheme of flow movement and changes in parameters in the VCA. Supercritical mode. The feed and bypass valves are shown.

As a result, the head wave shifts slightly towards the entrance (along the flow), and the flow itself in the channel accelerates and, when passing the throat, becomes supersonic with further acceleration in the expanding channel. A process occurs that is basically similar to the process in .

However, since the back pressure at the end of the channel (in front of the gas turbine engine compressor), although reduced, remains, a shock wave (S) is formed at some distance behind the throat, during which the flow becomes subsonic. This jump may have different position and intensity depending on the operating mode of the engine, and therefore its need for air.

Second mode. When throttling the engine and, therefore, reducing the required amount of air, the back pressure at the end of the inlet device channel increases and shifts the shock S towards the throat (against the flow). If the throat is optimal (mentioned above), then moving into it the jump disappears. This mode of operation of the air intake is called critical.

The third mode is subcritical . This mode is possible with further throttling of the engine. Now the flow along almost the entire length of the air intake channel becomes subsonic. This means that the action of backpressure from the end of the channel extends over its entire length. The consequence may be a shift of the head wave against the flow closer to oblique shocks (sometimes they say the wave is knocked forward - “knocked out wave”).

At the same time, due to a general decrease in flow speed, friction losses fall, which in itself. Certainly. Fine. But there is also “bad”, the harmful impact of which can be significant. The knocked-out bow wave can move so much against the flow that it begins to destroy the system of oblique shocks. The result may be an increase in losses, a decrease in efficiency and, most importantly, a decrease in the stability of the operation of the air intake, which can result in such an unpleasant phenomenon as air intake surge.

Unstable operating modes of a supersonic input device.

1. Surge.

The term “surge” was already encountered earlier when we got acquainted with gas turbine compressors. This word itself comes from the French pompage - “pump” or “pumping”. Therefore, it is applicable not only to aircraft compressors and pumps. It means the phenomenon of instability, non-stationary flow (gas or liquid), accompanied by low-frequency fluctuations in parameters, in particular pressure and flow (air for us).

The definition of surge mainly applies to blade machines. Such a machine, in particular, is the TRD axial compressor. Air intake, of course, does not belong to this type of mechanism, but is essentially a compressor and is fundamentally susceptible to such a phenomenon as surging.

Mechanism of occurrence.

Conditions for the occurrence of air intake surge can only appear at sufficient supersonic levels (M > 1.4...1.5). In this case, the operating mode should be subcritical, when the air intake channel is filled with excess air, which the engine is not able to let through, usually due to sudden throttling (reduction in speed).

Due to this overflow, the back pressure from the outlet of the air intake to the inlet increases. Because of this, the head wave is squeezed out (knocked out) against the flow and begins to destroy oblique shocks, first their part closest to the entrance to the air intake.

As a result, layers with lower total pressure appear in the air flow. These are those layers that did not pass through the shocks (due to their destruction, usually these are the outer layers) and those that touch the braking surface (due to losses in the near-wall boundary layer - usually these are the inner layers). The resulting so-called weakened zones (in Figure I, II, III).

Picture of the occurrence of IED surge. - b). Destruction of a system of oblique shocks knocked out by a wave - a).

And so, through these zones, with further throttling of the engine, the increased back pressure breaks out of the air intake channel. That is, compressed air is released into the atmosphere, or, more precisely, it is intensively released. At the same time, it pushes the head wave even further, which completely destroys the system of oblique shocks.

This position is maintained until the pressure in the air intake duct becomes lower than the inlet pressure (due to the release of compressed air through weakened zones). Then the air begins to move in the opposite direction - into the channel. The movement is so fast that the IED goes into supercritical mode. At the same time, a jump S appears in the space behind the throat.

Then, as the air intake channel is filled with air, back pressure appears and grows, which shifts this shock to the throat and the system transitions to a subcritical mode. This again creates the initial conditions for repeating the surge cycle and everything starts all over again. That is, there are fluctuations in air flow and pressure in the supersonic air intake.

These oscillations are low-frequency, usually from 5 to 15 Hz. Moreover, they have a fairly large amplitude and are very sensitive for the aircraft and crew. They appear in the form of shocks due to fluctuations in engine thrust (change in flow rate), as well as popping and shaking of the structure, especially in the air intake area.

The amplitude of such oscillations depends on the M number and can reach 50% of the pressure before surge at M > 2. That is, their intensity is quite high and the consequences for the power plant can be serious.

Firstly, the engine compressor may begin to surge, which can lead to its (engine) failure. Secondly, due to a sharp periodic decrease in air flow (that is, a sharp decrease in the amount of oxygen - especially at high altitudes), both afterburner and main burnout can occur, that is, the engine switches off automatically.

This is exactly what happened in the case of the MiG-25R aircraft mentioned at the beginning of the article, when at high supersonic speed due to a failure of the air intake control system, the controlled wedge suddenly straightened out completely, opening the entrance to the air intake to a large amount of air.

In addition, if pressure fluctuations are sufficiently intense, then the lining of the air intake channel can become deformed or even collapse with all the ensuing consequences. And the longer the channel, the higher the inertia of the flow and the stronger the surge phenomena.

Prevention (elimination) of surge.

Because of such serious possible consequences Surge is unacceptable in operation. If it does occur, then the main and main way to stop it is as quickly as possible. speed reduction. As mentioned above, the speed conditions for surge occurrence are M > 1.4...1.5.

If the flight takes place at a lower speed, then the oblique shock waves are less intense and are located at a greater angle to the braking surface (that is, less inclined), and therefore are located further (relatively of course) from the entrance plane and the air intake shell. In this case, the head wave, when exposed to backpressure, can move against the flow without the risk of destroying the shock system. That is, surging does not occur even with a large degree of engine throttling.

There are also constructive and technical ways to prevent this phenomenon. The simplest one – the use of so-called bypass flap. The principle here is clear: surging is prevented (or eliminated) by bypassing “extra” air from the air intake channel behind the throat. This reduces the back pressure that knocks out the head wave. Or, to put it simply, overflow of the air intake is eliminated.

Second constructive way is associated with a change in the throughput of the input device or, more precisely, the throughput of the shock wave system at the inlet to the air intake. But more on this below, but for now about one more unstable mode of operation of the air intake.

2. Itching of the entrance device.

The name is funny, but it's spot on. Itching is in some ways the opposite of surging, although it has virtually no effect on air flow. It represents pressure fluctuations with a fairly high frequency (100...250 Hz) and low amplitude (5...15% of the initial pressure). It occurs only in deep supercritical operating modes of the air intake, when the engine requires a lot of air and the air intake does not meet these needs.

As already mentioned, in this case, a supersonic flow with a shock wave S appears behind the throat. The interaction of this shock with the boundary layer of the flow becomes the reason for its non-stationarity. The further along the channel the shock is located, the thicker the boundary layer and the higher the intensity of the shock. Separation zones appear and increase, increasing the unevenness of the flow.

Diagram of the occurrence of air intake itching.

In these zones, periodic pressure fluctuations occur with a fairly high frequency. These pulsations are joined by high-frequency oscillations of the shock itself. They, in turn, affect the cladding and structural elements. It is these structural vibrations that “itch”, and quite unpleasantly.

Itching air intake Compared to surge, it is not so dangerous, however, due to the unsteadiness of the flow generated by it, it negatively affects the operation of the compressor in terms of reducing the stability of its operation. In addition, high-frequency vibrations can disrupt the operation of instruments and assemblies located in the airborne area, and physiologically have an unpleasant effect on the pilot, workplace which is most often located close to their source.

Itching is eliminated by throttling the engine, that is, reducing its need for air and eliminating the acceleration of the flow behind the throat. And it is prevented by using drainage and suction of the boundary layer, as well as its turbulization. Devices for this were mentioned above.

Another effective way similar to the second method of dealing with surge. This is a change in the air intake capacity. That is, the use of the so-called adjustable input device.

Adjustable supersonic air intakes.

All previous descriptions of air intakes and their features implied that they have a stationary, unchangeable geometry. That is, initially, during design, the input device is calculated for a specific operating mode, which is called the design mode (the shock waves are focused on the shell). During operation, its geometric dimensions and shape do not change.

However, in actual operation, the air intake does not always operate at its design level, especially for maneuverable aircraft. Atmospheric parameters and flight parameters, air intake and engine operating modes are constantly changing, and their combination most often does not fit into the concept of “calculated”.

This means that for the power plant as a whole, sufficiently high performance cannot always be achieved. Therefore, the goal of the designers (in our case, the designers of the turbojet air intake) is to achieve the maximum possible coordination of the operating modes of the air intake and the engine in order to obtain the most favorable efficiency characteristics of the entire power plant and at the same time ensure stable and safe work VCA for all combinations of engine operating modes, parameters and flight conditions possible in operation.

It is worth noting that the words “if possible” are used here for the reason that the requirements for maintaining high efficiency indicators (low total pressure loss, high pressure ratio, low resistance and sufficient flow) at the same time as a large margin of stability are contradictory.

For example, from the point of view of maintaining high efficiency and the absence of flow pulsations due to the interaction of the boundary layer with the shock S, the subcritical operating mode of the air intake is more advantageous. However, the stability is low, disturbances can propagate against the flow (subsonic in the channel), and the operating parameters approach the surge limits.

On the contrary, in the supercritical regime the bow wave is far from the system of oblique shocks, and the stability of the air shock is high. But on the other hand, the efficiency decreases, in particular due to the effect of the S jump on the boundary layer. With deep overcriticism, this jump is so close to the exit from the OT that the likelihood of itching increases significantly.

Therefore, in practice, one has to choose something in between and often allow for some reduction in efficiency for reasons of ensuring stable operation modes of the air intake. This is facilitated, in particular, by the shape of the flow part (like a Laval nozzle), which, in principle, is more conducive to operation in a supercritical mode.

For traditional air intakes with a constant geometry, the possibilities for achieving the above-mentioned coordination of operating modes are not too high, especially if the aircraft are designed for operation at high supersonic speeds (M>2). This means that the speed range of the aircraft on which they are installed will not be very wide.

Therefore, almost all modern supersonic input devices equipped with a geometry changing system to ensure consistent collaboration with the engine throughout the entire speed range.

Physical meaning of IED regulation is to ensure compliance of the air intake capacity with the engine capacity in all modes of its operation and all operational Mach numbers of the flight. The capacity of the air intake is determined by the capacity of the jump system and throat.

Regulation occurs due to the movement of the so-called wedge, consisting of several panels - for flat (box-shaped) air intakes, or due to the axial movement of a special stepped cone (central body) - for axisymmetric air intakes. In this case, the position of the shock waves and the area of the throat change, and therefore the throughput and stability margin.

Picture of flat air intake regulation. The rotating edge of the shell is shown.

Picture of the regulation of the frontal axisymmetric air intake. The feed and bypass valves are shown.