Just in time technology. The logical concept of just in time. Waste is an element of the production process that increases costs and does not add value.

Just in Time (Just in time) or JIT is a production management concept that aims to reduce inventory. In accordance with this concept, the necessary components and materials arrive in the right quantity at the right place and at the right time.

The use of Just in Time improves production efficiency by reducing waste. Waste refers to any activity that adds value but does not add value to the product - unnecessary material movements, excess inventory, etc.

JIT is primarily applied to regularly repeating processes. These are production processes in which products or components are mass-produced (large-scale, mass). The effective use of JIT is possible by synchronizing process flows and material flows in production.

The basic elements of Just in Time were developed in the 1950s in Toyota factories and became known as the Toyota Production System. In the early 70s, Just in Time emerged as a production management system and spread to many Japanese factories, and in the 80s it appeared in American and European industries.

Goals Just in Time

For any organization seeking to compete in the market, an important advantage is to provide the consumer with the necessary and high-quality goods at a lower price in the shortest possible time.

Just in Time makes it possible to achieve this by setting and achieving a number of goals:

- Zero Defects – This goal aims to reduce the number of defects in manufacturing. In the course of production, not a single, even minor defect should occur.

- Zero workpiece setup time- installation time should be kept to a minimum. Reducing installation time results in a shorter production cycle and a reduction in inventory in production.

- Zero Inventory - Inventory, including those in the process of being processed, erected, and assembled, should tend to zero.

- Zero unnecessary operations- in the JIT system, this means that all activities that do not add value to the product should be excluded from the production process.

- Zero waiting time– the waiting time should tend to zero. In this case, the accuracy of production planning and the consistency of work increase.

Key elements of Just in Time

At the heart of the Just-in-Time production management system are several key elements:

- Stable production program. For the Just in Time system to work, it is necessary to create a uniform load of all production and assembly operations. A change in the program should occur only due to a change in demand.

- Reducing the time of installation operations. The goal is to achieve "one-touch" machining parts. This can be achieved by optimizing planning, changing production operations or the shape of the workpieces.

- Reducing lot sizes(both in production and in procurement). For this element of Just-in-Time to work, there needs to be closer cooperation with suppliers. More frequent deliveries will be required, so suppliers must ensure reliable and accurate deliveries.

- Reducing waiting time(during production and delivery). Reducing waiting times can be accomplished by placing equipment closer friend to each other, the use of batch processing technologies, reducing the length of the processing queue, increasing coordination and consistency between sequential processes. Reduced waiting times for deliveries can be obtained by closer proximity to suppliers.

- Carrying out preventive maintenance. Preventive maintenance of equipment should be carried out during periods of downtime or non-working hours.

- The use of a "universal" workforce."Just in time" system implies management training for workers various types equipment and technology. This allows workers to carry out maintenance and quality control operations from their workplace. JIT requires the creation of competent production teams who are fully responsible for the results of their work.

- Application of the Zero Defects program. For the Just in Time system to work, all actions that lead to defects or defects must be eliminated, because. this system does not provide reserves for their elimination. The implementation of the program makes it possible to achieve personal responsibility of employees for the quality of the work they perform. Also, in the JIT system, each worker should have the right to stop production if a violation of the quality of work is possible.

- The use of small batches when moving. To implement this element, the JIT system provides for the use of a signaling system (for example, kanban cards). This ensures the transfer of parts between workstations ( production equipment) in small quantities. Ideally, one part should be transferred per unit of time.

Advantages and disadvantages of Just in Time

Just in Time is a system that has been successfully applied in many manufacturing plants. Like any production system, JIT has certain advantages and disadvantages.

The main advantages of the system "Just in time" include:

- Cash Reduction required for inventory management. Less inventory reduces the quantity financial resources"frozen" in stocks.

- Possibility to use the area for other needs previously reserved for reserves. The Just-In-Time system reduces inventory of raw materials, inventory in production, and inventory of finished goods. As a result, significant areas can be released that can be used for other purposes.

- Reducing the volume of unsold goods with a reduction in demand. The goal of Just-in-Time is to produce such production quantities that the consumer needs. Therefore, if the demand for products drops sharply, then in the JIT system the amount of unsold goods will be minimal.

- Reducing the volume of production batches. This allows you to quickly respond to changing market needs. Due to the small batches in the JIT system, it is possible to introduce changes faster based on customer needs.

- Defect reduction, which leads to a reduction in marriage and the cost of its correction. For the effective operation of the "Just in Time" system, the number of defects detected in production should tend to zero. To achieve this, a lot of efforts are being made to improve the quality of work.

The most serious and obvious shortcomings of the Just-in-Time system are:

- Decreased ability to correct marriage that has arisen and missed for the next operation. Because JIT does not provide for stocks and reserves, both material and temporary (or they are minimized), then in the production process it becomes quite difficult to remake or correct the marriage. To correct the marriage, it is necessary to stop all production.

- Strong production dependency on the quality of the suppliers. Suppliers are usually outside the control of the company, so any problems in the supply chain can cause a stop in production.

- Minor opportunities to satisfy sudden increase in demand. Because Since the JIT system does not include stocks of finished goods, additional time is required to meet the increased demand.

Implementation of the Just in Time system

The implementation of the JIT system requires a large and long-term effort from the organization.

The key success factors for implementation are:

- Support by managers of all levels of management of the organization;

- Adequate allocation of resources;

- Building long-term, trusting relationships with suppliers;

- Change corporate culture organizations;

- Changing the flow of processes and principles of organization of production;

- Optimization of loading and equipment operation;

- Optimization of equipment maintenance in order to reduce the number of breakdowns;

- Implementation of quality improvement programs;

- Reducing delivery times and increasing their quantity. Implementation of a system of frequent deliveries in small batches;

- Implementation of a search, analysis and loss reduction system.

The JIT implementation process is long and labor intensive. For the system to work, it is necessary to apply various methods, tools and quality techniques. But most importantly, it will require a change in the minds of employees and corporate culture.

slide 2

Features: the basic basis of the Toyota Production System, the method of organizing production; during production process the parts required for assembly are on the production line exactly at the moment when it is needed, and in exactly the right quantity. Results: Downtime is eliminated, inventory is minimized, or reduced to zero. Key features: Only the necessary supplies are available when needed; quality is improved to the state of "zero defects"; the duration of the production cycle is reduced; the size of the queue and the size of the production batch are reduced; operations are gradually modified; costs are minimized. 2

slide 3

Just-in-time method invented in 1954 by Toyota Corporation Traditional production organization Just-in-time production organization 3

slide 4

JIT 4 Applications

slide 5

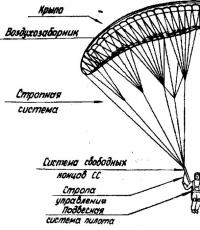

The movement of raw materials, materials, semi-finished products, finished products when using the "just in time" method 5

slide 6

System components: production leveling; pull production; Kanban system (labels or signs); order in the workplace; production in small batches; reduction of reloading time; end-to-end preventive maintenance; end-to-end quality control; purchase according to the Just-in-time system; balanced production lines; flexible production; small group activities; personnel training under the Just-in-time system is carried out in short sessions (a few hours a week) to avoid information overload; Just-in-time production is preceded by Just-in-time information flow. 6

Slide 7

Kaizen, kaizen- (Japanese 改善 kaizen, romaji Kaizen) is a Japanese philosophy or practice that focuses on the continuous improvement of manufacturing, development, supporting business processes and management, as well as all aspects of life. "Kaizen" in business is continuous improvement, from production to top management, from the director to the ordinary worker The goal of kaizen is production without waste. 7

Slide 8

Kaizen principles: Production pull system (pull-principle); Continuous flow production; Tact time. Japanese management achieves the "just in time" principle by systematically avoiding three undesirable components: MURI - surpluses; MUDA - losses; MURA - imbalance. eight

Slide 9

Just-in-time. Losses (Muda)

Slide 10

Exactly-in-time (Just-in-time). Losses (Muda)

MUDA - wastage Waste (muda) is any activity that consumes resources and time but does not create value. Losses occur both in management and in production. ten

slide 11

Exactly-in-time (Just-in-time). Losses (Muda) 11

slide 12

Exactly-in-time (Just-in-time). Losses (Muda) 12

slide 13

Types of losses Just-in-time. Waste (Muda) 13 1. Overproduction of materials or information. 2. Loss of time due to waiting. 3. Unnecessary transportation of materials or information. 4. Extra processing steps. 5. Availability of any, except for the minimum required, stocks. 6. Unnecessary movement of people during work. 7. Production of defective products. 8. Loss of staff creativity.

Slide 14

Practical implementation of the method of eliminating losses: Exactly-in-time (Just-in-time). Losses (Muda) 14

slide 15

Loss Prevention Steps 15

slide 16

Preconditions for Effective Method 16

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Hosted at http://www.allbest.ru/

Logic concept just in time

Introduction

1.1 JIT concept

1.2 Goals of the system

1.3 Building Blocks System

Chapter 2. Micrologistic systems based on the JIT concept

2.1 Basic concepts

Chapter 3. Practical application of the logical concept of JIT

3.1 Implementation of Just In Time

3.2 JIT example

3.4 Future of JIT

Conclusion

List of used literature

Introduction

Just-in-time production. JIT what is it? To fully understand JIT, you need to have a good understanding of its basic logic. Without a conceptual framework, the study of JIT becomes a confusing array of methods, acronyms, and river drainage analogies. This course work is devoted primarily to the philosophy and main principles of JIT. Its goal is to create a foundation on which to proceed to further, more detailed study JIT and its results.

Why is Just-In-Time (JIT) manufacturing so interesting? First of all, because of the success of Japanese manufacturers. JIT has clearly demonstrated the ability to simultaneously improve quality, reduce costs and reduce delivery times. Therefore, Japanese manufacturers have achieved a dominant position in the world markets for many products, from consumer electronics to cars.

A lot has been written about the harmony of an enterprise operating on the principles of JIT. However, to achieve such simplicity and harmony, you need to go through a complex and intense process, and the chances of success in it are not so great. The implementation of JIT is associated with a certain risk, however, if successful, the company will receive a worthy reward in the form of competitive advantage. In some markets, there is little to no choice: the effectiveness of the JIT approach has made it a must-have tool to compete. AT modern conditions global competition understanding JIT is extremely important for making qualified decisions about the organization of production. This article, or more precisely, the study of the underlying philosophy of JIT, will serve as a help for this understanding.

A number of companies, Toyota among the first, spent years in the 1970s developing the concept of "just in time" (just in time) or JIT, another name for "just in time". These methods have proved so effective that all large organizations now use elements of this approach to some extent. The traditional approach to work organization assumes that stocks are an important element of the entire system, ensuring that operations do not fail. MRP reduces inventory using the master schedule in a way that provides a closer match between material supply and demand, while still maintaining some safety stock in case of unforeseen problems. Obviously, the higher the degree of correspondence between supply and demand is ensured, the less stock we will need. If we manage to fully eliminate the mismatch between supply and demand, we will not need stocks at all. This is the basis of just-in-time work.

The relevance of the topic of this term paper that there are many interpretations of this method. Most often, the basis of the method is defined as the work of an enterprise without a warehouse and stocks; procurement and production are carried out accurately and on time, managed by the KANBAN system, or "work from wheels".

Conceptually JIT- the approach served as the basis for the subsequent introduction of such logistics concepts / technologies as Lean Production, (“Flat”, or “thin” production) and Value added logistics - “Value Added Logistics”

Thus, the subject of the course work is the JIT concept and micrologistics systems based on it: the KANBAN production management system and the TMQ quality management system and others.

Chapter 1. Fundamentals of the logical concept of JIT

1.1 JIT concept

The main idea of JIT: if the production schedule is set (abstracting from demand and orders), then it is possible to organize the movement of material flows so that all materials and components will arrive in the right quantity at the right place and exactly at the appointed time for production or assembly. In this case, stocks of material resources are not needed. Thus, the main task is to coordinate supply with production management, or more abstractly, to synchronize the needs for MP (material resources) with the flow of MP.

The main assumption is the possibility of synchronizing the emergence of MR needs with their supplies. There are at least two main assumptions of this concept: it is possible to ensure the supply of MR exactly on time; it is possible to predict the demand for finished products (FP) at least for the delivery time + production time; Hence the requirement for a quick response to changes in demand and, accordingly, a quick change in the production program.

The essence of the JIT system is to abandon the production of products in large batches. Instead, a continuous-flow object production is being created. At the same time, the supply of production shops and sites is carried out in such small batches that it essentially turns into a piece. This system considers the presence of inventory as an evil, the existence of which makes it difficult to solve many problems. Requiring significant maintenance costs, large inventories adversely affect the lack of financial resources, flexibility and competitiveness of the enterprise. From a practical point of view, the main goal of the JIT system is to eliminate any unnecessary costs and effective use production potential of the enterprise.

The JIT system is more demand-driven than the traditional "throw-to-market" method. Under this system, the principle is to produce products only when they are needed, and only in such quantities as buyers require. Demand accompanies products through the entire production process. Each operation produces only what is required for the next operation. The production process does not start until a signal is received from the site of the subsequent operation to start production. Parts, assemblies and materials are delivered only at the time of their use in the production process.

The JIT system involves reducing the size of processed batches, virtually eliminating work in progress, minimizing inventory and production orders not by months and weeks, but by days and even hours. Under these conditions, the system is also simplified production accounting, since it becomes possible to account for materials and production costs on one combined account. In addition, when using this system, part of the enterprise's costs from the category of indirect ones goes into the category of direct ones. For example, in the conditions of organizing production according to the JIT system, workers production lines engaged in the production of products are also obliged to produce Maintenance, repair and adjustment work, which under traditional conditions are carried out by other workers and are classified as indirect costs. This, in turn, increases the accuracy of calculating the unit cost of production.

The concept of JIT is closely related to functional logistics cycles and their components. In the ideal case, MR, NP or GP should be delivered to a certain point in the supply chain (channel) at the very moment when they are needed (not earlier and not later), which eliminates excess stocks in the functional areas of the company's business. Many modern medicines based on the JIT approach are focused on short components of logistics cycles, which requires a quick response of the medicines to changes in demand and, accordingly, a flexible production program.

The logistics concept of JIT is characterized by the following main features:

Minimum (zero) guarantee/insurance reserves of MR, NP, GP;

Short production (logistics) cycles;

Small volumes of GP production and replenishment of stocks (supplies);

Relationships (purchasing MR) with a small number of reliable suppliers and carriers;

Effective information support;

High quality GP and logistics service.

An interesting example illustrating the essence of "just in time" work is the operation of a gas stove on bottled gas and on gas supplied through a pipeline. In the first case, sometimes there is a discrepancy between the presence of fuel in the cylinder and the need for it. To eliminate interruptions, it is necessary to purchase gas cylinders in advance, i.e. create stock. In the second case, the supply of gas exactly matches the demand, and the consumer does not have any fuel supply.

work logistics system, built on the principles of the "just in time" concept, can be imagined as a two-bin inventory management system. One bunker is used to meet the demand in production or marketing, respectively, for material resources or finished products, the other is replenished as the first one is spent. Emphasis is placed on the placement of equipment in such a way as to ensure a continuous production process. Where possible, automation of both the production process and the processing of raw materials is being introduced. Often the equipment is placed in the shape of the letter U, which contributes to teamwork, flexibility of work, cyclical processing of raw materials and products. At the same time, product developers strive to standardize time cycles and the production of a constant set of products based on monthly production plan throughout the entire system. This practice turns the production process into a cycle of at least a month.

Thus, the production of finished products in small batches for relatively short production cycles determines the duration of the supply cycles of material resources.

This concept is based on the belief that inventories arise due to bad management, poor coordination of work and therefore problems are hidden in stocks. From this follows the conclusion that it is necessary to find the causes that cause the difference between supply and demand, improve the performance of operations, after which the stocks will disappear. More broadly, JIT considers an enterprise as a set of problems that hinder the efficient execution of operations, for example, long lead times, order delivery instability, operations that are unbalanced with each other, limited capacity, equipment breakdowns, defective materials, work interruptions, unreliable suppliers, low GP quality, too much paperwork, and more. Managers try to solve these problems by building reserves, acquiring additional capacity, installing backup equipment, hiring "firefighting" specialists, and so on. However, in reality, these actions only hide the causes of problems. A constructive approach is to identify real problems and solve them. The concept of JIT leads to a change in views in the following areas:

Stocks. Organizations should identify and address inventory issues by aiming for minimum (zero) inventories of WIP, WIP, and WIP.

Quality. It is necessary to achieve not an acceptable level of marriage, but its complete absence on the basis of integrated quality management.

Suppliers. Customers must fully rely on their suppliers, so they need to establish long-term partnerships with a small number of reliable suppliers and carriers.

Lot size. It is necessary to look for ways to reduce the volume of production batches, to achieve short production cycles so that excess production does not accumulate in the stocks of SOEs.

Lead time. It is necessary to reduce lead times in order to reduce the uncertainties that can change the situation during a long delivery time.

Reliability. All operations must run continuously without failure, i.e. there should be no equipment breakdowns, marriage, absenteeism, etc.

Employees. A spirit of cooperation is needed, both between workers and between managers and workers. the well-being of all depends on the general success in work; all workers should be treated equally and fairly. Any creative initiative expressed by any employee about possible improvements in work is encouraged.

Information support should allow for the rapid exchange of information and synchronization of all processes for the supply of MR, production and assembly, and the supply of GP.

Thus, JIT is not only a way to minimize inventory, but also eliminate waste from any type of resource, improve coordination and increase efficiency.

1.2 Goals of the system

Final goal systems are a balanced system; that is, one that provides a smooth and fast flow of materials through the system. The main idea is to make the process as short as possible using resources optimal way. The degree to which this goal is achieved depends on the extent to which additional (auxiliary) goals are achieved, such as:

Eliminate failures and violations of the production process.

Make the system flexible.

Reduce preparation time for the process and all production time.

Minimize inventories.

Eliminate unreasonable costs.

Process failures and disturbances have a negative impact on the system, disrupting the smooth flow of products, so they must be eliminated. Breakdowns are caused by a wide variety of factors: poor quality, equipment failure, schedule changes, late deliveries. All these factors should be eliminated whenever possible.

Lead times and production times lengthen the process without adding anything to the cost of the product. In addition, the length of these deadlines has a negative impact on the flexibility of the system. Therefore, their reduction is very important and is one of the goals of continuous improvement.

Inventories are unused resources that take up space and increase the cost of production. They should be minimized or, if possible, eliminated altogether.

Unjustified expenses represent unproductive resources; eliminating them can free up resources and expand production. In the Just-in-Time philosophy, unreasonable expenses include:

Overproduction;

waiting time;

Unnecessary transportation;

Storage of inventories;

Marriage and waste;

Inefficient working methods;

Product defects.

The presence of such unreasonable expenses indicates an opportunity for improvement, or a list of unreasonable expenses identifies potential goals for continuous improvement.

1.3 Building Blocks System

Design and production in the JIT system are the basis for fulfilling the above goals. This foundation consists of four building blocks:

Product development.

Process development.

Personnel/organizational elements.

Planning and production management.

Speed and simplicity are two common elements that run through these building blocks.

1. Product development. Three elements of product design are key to a just-in-time system:

Standard accessories

Modular design

Quality

The first two elements are related to speed and simplicity.

Using standard parts means workers have to deal with fewer parts, which reduces training time and costs. Purchasing, processing and quality control are more standardized and allow for continuous improvement. Another important advantage is the use of a standard processing procedure.

Modular design is a kind of extension of the concept of standard components. Modules are groups of parts assembled into a single unit (and therefore representing a separate unit). This greatly reduces the number of parts to work with, simplifies assembly, purchasing, processing, training, and so on. Standardization has the added benefit of reducing the length of the material list for different products, i.e. simplifying this list.

The disadvantages of standardization are that products are less diverse and resist changes to their standard designs. These inconveniences are somewhat reduced where different products share common parts or modules. There is a tactic sometimes referred to as "delayed differentiation": Decisions about which products will go into production are delayed while standard parts are being produced. When it becomes obvious which items are needed, the system reacts quickly by producing the remaining non-standard parts for those items. Quality is the basic prerequisite for a just-in-time system. It is vital for JIT systems, as poor quality can cause serious disruptions in the production process. The system aims for a smooth workflow; the appearance of problems due to low quality causes failures in this stream.

Since small production lot sizes and the lack of safety stock result in a minimum amount of work in progress, the production process is forced to stop when a problem occurs. However, it cannot resume until the problem is resolved. It is clear that shutting down the entire process is very costly and lowers the planned output level, so it is absolutely essential to avoid shutting down the system whenever possible and resolve issues quickly if they occur.

JIT systems use a three-stage approach to quality. The first part is to introduce quality into the product and into the manufacturing process. High level quality is achievable because "just-in-time" systems produce standard products, using respectively standard working methods and standard equipment, workers are accustomed to their production operations and know them well. In addition, all the costs of project quality (i.e., the formation of product quality at the design stage) can be spread over many products, while receiving a small cost per unit of product. It is very important to choose the appropriate level of quality in terms of the end user and production capabilities. Thus, product design and process development must go hand in hand.

2. Process development. For "just-in-time" systems, seven aspects of product development are particularly important:

Small production batches

Reduced lead-to-production time

production cells

Limiting the volume of work in progress

Quality improvement

Production flexibility

Small inventories

The small volume of the production lot and the purchase lot provides a number of advantages that allow JIT systems to function efficiently. First, when small production lots move through the system, the amount of work in progress (i.e., materials that are in the process of being processed) is significantly less than with large lots. This reduces the cost of storage, requires less storage space, and does not create unnecessary space occupancy in the workplace. Second, when quality issues arise, inspection and rework costs are lower because there are fewer units in each batch to be inspected and reworked. In addition, small batches provide more planning flexibility.

A small production batch and a changing range of products require frequent re-equipment and readjustment of equipment (i.e. preparation for production). If such training cannot be done quickly and relatively inexpensively, time and cost will become inhibitory factors. Often, workers are trained to prepare their equipment for the production process themselves. In addition, special programs are used to reduce the time and cost of preparing for production; while workers become a valuable part of the process.

In addition, to reduce the time and cost of preparation, you can use the grouping of technologies - the union of similar operations. For example, the production of various parts that are similar in shape, material, etc. may require the same type (similar) preparation. Their sequential processing on the same equipment can reduce the necessary changes; only minor adjustment is required.

A common feature of "exact-term" systems is a set of production cells. They combine equipment and tools for processing a group of parts with similar technological requirements. At their core, cells are highly specialized and efficient production centers. Among the most important advantages of production cells: the transition time to a new type of product is reduced, equipment is used efficiently, it is easier for workers to master related specialties. The combination of high cell efficiency with small production batch sizes results in a minimum work in process.

Continuous quality improvement often aims to find and eliminate all causes of problems.

Just-in-time systems are designed to keep inventory to a minimum. According to the JIT philosophy, holding inventory is a waste of money. Inventory is a kind of buffer that hides recurring problems. These problems are not solved, partly because they are hidden, and partly because having a reserve stock makes them less serious.

Using a JIT approach, inventory levels are gradually lowered to open up problems. When problems are discovered and solved, the level of stocks is lowered again, the next layer of problems is found and solved, and so on.

Personnel organizational elements

There are five personnel and organizational elements that are particularly important for JIT systems.

Workers as an asset

Training of workers in related specialties

Continuous improvement

Accounting

Enterprise / project management

The fundamental principle of the JIT philosophy is to regard workers as the active capital of the enterprise. Well trained and motivated workers are the heart of the system. They have more decision-making power than their counterparts in traditional systems, but accordingly more is expected of them.

Workers are trained in related trades to perform multiple elements of the process and operate a variety of equipment. This gives the system additional flexibility, because workers can help each other when there are “congestions” in the production process or replace an absent colleague.

Workers in a JIT system have a greater responsibility for quality than workers in traditional systems. They are expected to contribute to problem solving in a process of continuous improvement. Workers in JIT systems typically receive extensive training in statistical process control, quality improvement, and problem solving.

Other feature"precise-term systems" - a way to allocate overhead costs. Traditional accounting methods sometimes distort the allocation of expenses because they allocate them on the basis of hours directly worked.

Another feature of just-in-time systems has to do with leadership. The manager is required to be a leader and assistant, and not just give orders. Two-way communication between managers and workers is strongly encouraged.

1.4 Production planning and control

Especially important for JIT systems are 5 elements of production management and planning:

Work transfer system.

visual systems.

Close relationships with suppliers.

Reducing the number of transactions and the volume of office work.

The main emphasis in JIT systems is on achieving stable, balanced work schedules. To this end, the main production schedules are designed to ensure an even workload of production facilities.

The terms "pull" and "push" are used to describe two various ways moving work through the production system. In "push" systems (push system), at the end of work at the production site, the products are pushed to the next site; or, if this operation was the final one, finished products are pushed to the warehouse of final products. In "pull" systems (pull system) management of the movement of work is assigned to the subsequent operation: each work site, as necessary, "attracts" products from the previous site to itself; products from the final operation are "pulled" by the consumer's request or control schedule. Just-in-time systems use a "pull" approach to manage the flow of work, with each job site producing output in response to the demand of the next job site. Traditional manufacturing systems use a "push" approach to push work through the system.

As a rule, just-in-time systems have very close relationships with suppliers who must ensure frequent deliveries of small batches of high-quality products. In a traditional production system, buyers control the quality of purchased products themselves, checking supply lots for quality and quantity, and returning defective goods back to the supplier for rework and replacement. In just-in-time systems, there is practically no spare time, so low-quality products disrupt the smooth movement of work through the system. Moreover, checking incoming purchases is considered a waste of time because it adds nothing to the cost of the product. For this reason, the responsibility for quality assurance is transferred to suppliers. Buyers work with suppliers to help them achieve the required level of quality and understand the importance of producing products of consistent high quality. The ultimate goal of the buyer is to assign a certificate of conformity to the supplier as a manufacturer of high quality goods. The bottom line is that the supplier can be fully relied upon, with no doubt that his deliveries will meet a certain level of quality and do not need to be checked by the buyer.

Technological changes are the most expensive among all the listed operations. JIT systems reduce costs by reducing the number and frequency of such operations. For example, a supplier delivers products directly to production, completely bypassing warehouses - thereby eliminating the activity associated with placing materials in a warehouse and then moving them to production sites. The endless search for ways to improve quality that permeates the entire JIT system eliminates many of the activities associated with product quality - and the associated costs. The use of bar coding (not just in "precision" systems) helps to reduce data entry operations and increases the accuracy of the data.

1.5 Advantages and disadvantages of JIT technology

From a logistical standpoint, JIT is a fairly simple binary inventory management logic without any restriction on the minimum inventory requirement, according to which MP flows are carefully synchronized with the need set by the production schedule for the release of finished products. Such synchronization is nothing more than the coordination of two functional areas of logistics: supply and production support. In the future, the JIT ideology was successfully promoted in the distribution of products, and at present - in macrologistics systems of various levels and purposes.

The main advantages of just-in-time technologies, which explain their widespread use in logistics practice, are:

Low level of stocks of MR, NP, GP.

Reducing production space.

Improving the quality of products, reducing marriage and rework.

Reducing production time.

Increase flexibility when changing the product range.

Smooth production flow with rare failures caused by quality problems; more short time preparation of the production process; multi-skilled workers who can help or replace each other.

High performance and equipment efficiency.

Participation of workers in solving production problems.

Good relationship with suppliers.

Less non-manufacturing work, such as warehousing and moving materials.

You can also consider specific benefits for buyers and suppliers.

Benefits for the buyer

Close relationships provide an opportunity for dialogue leading to a precise definition of benefits.

Maintaining the lowest level of stocks of raw materials and components.

Cost savings until inventory is needed.

Savings in terms of time and space.

Reducing the cost of security and insurance.

Reducing the likelihood of theft, write-offs and damage.

For wholesalers and retailers - reduction of warehouse space and release of retail space.

Reducing the required vehicle fleet.

Benefits for the supplier

Guaranteed contract.

Obtaining useful information in connection with working in closer contact with the buyer.

Close relationships contribute to the formation of loyalty, trust and the conclusion of long-term contracts.

The main disadvantages of the just-in-time system are:

* the difficulty of ensuring high consistency between the stages of production;

* Significant risk of disruption of production and sale of products.

Likewise, there are disadvantages specifically for buyers and suppliers.

The organization of such systems may require high initial costs for all participants in the logistics supply chain.

Disadvantages for the buyer

Lack of required product.

Increase in cost due to the refusal to purchase large lots.

Problems with delivery and transport associated with the need for frequent transportation.

Disadvantages for the supplier

Payments are distributed over time throughout the duration of the contract.

The probability of erroneous orders when the needs and sales volumes of the buyer change.

Increasing the cost of storage and delivery of goods.

Increase in security and insurance costs.

Also, the disadvantages of the JIT system are the complexity of its implementation and the numerous problems that arise when implementing the concept of "just in time". These issues include:

High initial investment and costs for the implementation of JIT (purchase of high-quality expensive modern equipment, costs for training specialists and high wages, increased production costs due to small production batches, etc.).

Inability to cope with unforeseen circumstances (breakdowns, strikes of supply workers, etc.);

Dependence on the high quality of the supplied materials.

· The need to work in stable production, although demand often fluctuates.

Decreased flexibility in meeting changing customer needs.

Difficulty in reducing changeover times and related costs.

The inability of individual vendors to work in JIT mode.

Problems linking JIT to others information systems partners.

The need to change the overall layout of buildings.

Work of employees in an environment of increased stress.

Lack of spirit of cooperation and trust between employees.

The inability of individual employees to take on greater responsibility.

Chapter 2. Micrologistics systems based on the concept of JIT

2.1 Basic concepts

Micrologistics systems are subsystems, structural components of macrologistics systems. Micrologistics systems cover the scope of an individual enterprise, are built from the standpoint of the strategic goals of firms and optimize the main processes, provide a solution to local issues within the framework of individual functional elements of logistics systems. It can be industrial, trade enterprises, territorial-production complexes.

Logistics systems that use the principles of the "just in time" concept are "pull" systems (pull systems), in which the placement of orders for the replenishment of stocks of material resources or finished products occurs when their number in certain links of the logistics system reaches a critical level. . At the same time, stocks are "pulled" through distribution channels from suppliers of material resources or logistics intermediaries in the distribution system. logistics concept just in time

The pulling system is a production organization system in which parts and semi-finished products are fed to the next technological operation from the previous one as needed.

Here, the central control system does not interfere in the exchange of material flows between different sections of the enterprise, does not set current production targets for them. The production program of a separate technological link is determined by the size of the order of the next link. The central control system sets the task only for the final link of the production technological chain.

2.2 Micrologistics systems

2.2.1 Efficient customer response (ECR) concept

JIT is forcing suppliers to change the way they work to deliver faster, higher quality, smaller batches and absolute reliability. The obvious way to meet these requirements is for vendors themselves to adopt JIT techniques. This ensures that the entire LC will work in concert based on the same goals and principles. The concept of efficient consumer response or ECR involves the expansion of the JIT zone throughout the supply chain. Other names used are quick response (quick response, QR), continuous replenishment planning (CPR). Under ECR conditions, the required materials are communicated back through the supply chain, causing MPs to move forward, i.e. ECR "stretches" MR through the organizations included in the LC.

In 1985, one of the world's first ECR partnerships was formed in the US, involving retailer J.C. Penney, fabric manufacturer Burlington, and clothing manufacturer Lanier Clothing. As a result, they increased sales by 22% and reduced inventory by 50%.

Great interest in ECR arose in the second half of the 1990s in the grocery industry. Currently, in supermarkets using this approach, when a customer is sold a pack of biscuits, the checkout automatically sends a message to the supplier to replace this pack, after which the supplier's system sends a similar signal to its supplier, i.e. this signal goes all the way back. It was within the framework of ECR that the technology of inventories managed by the seller arose (see paragraph 1.3.5).

Necessary conditions for the implementation of the concept of "just in time":

Availability in economic system reliable suppliers. For example, American and European manufacturers were able to implement this concept 10-15 years later than the Japanese due to low reliability of supply.

Partnership relationships between organizations in the supply chain.

Use of systems for exchanging information about the required MPs, such as kanban for JIT and electronic data interchange for ECR.

High speed of physical delivery of MR, including by reducing the time of intermediate storage and waiting for cargo handling.

Accurate information about the current state of production, accurate forecasts for the near future. To do this, when organizing and managing production processes, reliable telecommunication systems and information and computer support should be used.

ECR Implementation Challenges

Seasonality in the production of some inputs, such as crops.

Disagreement of some of the LC organizations (does not want or cannot) work in ECR mode - this interrupts the flow.

If the LC crosses a boundary where the MP is slowing down, or encounters other performance-degrading problems, ECR will not work.

2.2.2 In-house KANBAN system

Micrologistic kanban system is one of the first attempts to put the concept of "just in time" into practice.

Japan made its contribution to the development of the global logistics system, which developed and applied for the first time in the world the progressive logistics concept "just in time" - JIT (just in time) and the in-house KANBAN system.

In practice, pulling in-house logistics systems include the KANBAN system (translated from Japanese as a card), developed and implemented by Toyota (Japan).

This system combines the features of a "just in time" system, in particular, a small amount of stock, and separate production units. The systems are most applicable to products that are produced in high volumes on a regular basis. They are much less applicable to expensive or large items that have high storage or shipping costs; systems are less applicable to infrequently and irregularly used products or to manufacturing enterprises that are not divided into small production units.

The KANBAN system does not require a total computerization of production, however, it implies a high discipline of deliveries, as well as a high responsibility of the personnel, since the central regulation of the intra-production logistics process is limited. The KANBAN system allows you to significantly reduce inventories.

"Pulling" micro-logistics systems such as "KANBAN", eliminating excess stocks, can work effectively only with relatively short production cycles, accurate demand forecasting and some other production and technological conditions. To correct the shortcomings inherent in both systems, attempts were made to combine them in a single planning, production and dispatching computer complex.

The difference between Just-in-time and KANBAN.

Many people confuse or fail to clearly distinguish between Just-in-time and KANBAN. I am sure this simple and small article will help them.

When managing inventory, it is always necessary to remember that excess inventory is not good. It is this philosophy that defines the Just-in-time approach to inventory management. The goal of this approach is to increase return on investment (ROI) by reducing inventories in production and their corresponding costs of building those inventories. One of the key elements in the JIT system is KANBAN. This Japanese word is made up of two words, where KAN means "visual" and BAN means "cards". That is, literally, KANBAN means visual cards. These cards play an important role in the implementation of JIT, because. serve as a kind of traffic lights - visual signals for action. And although JIT and KANBAN are often confused with each other, they are not the same thing. In this case, let's determine how these two related concepts differ.

First, what is JIT? It is a method of enterprise inventory management designed to improve return on investment, efficiency and quality of work by radically reducing inventory levels. Proponents of the JIT method see inventories more as a source of cost, rather than as an additional value, in contrast to supporters of traditional practice. It focuses on having required material at the right time in the right place and required quantities. And, despite some idealism of this approach, it gives companies a number of advantages:

1. It simplifies warehouse material flow, making it more controllable.

2. Deliveries are synchronized with the production plan, storage costs are reduced, flexibility is increased /

3. The production schedule and working hours are tied to production and supply, which reduces the number of overtime and frees up time for staff development.

4. Optimization is achieved by redistributing personnel with a variety of skills to those parts of the process where at that moment there is a need for labor.

5. Finally, special attention is paid to the relationship of the company with its suppliers. There is also a drawback to this strategy - JIT makes suppliers very susceptible to possible fluctuations in demand. Strong and long-term relationships with the supplier make it possible, however, to minimize this disadvantage.

KANBAN is not a stock control system. Rather, it is a planning system that tells the company what to produce, when to produce, and how much to produce. This is a suitable element of implementing the JIT concept. KANBAN is used as a demand indicator that immediately sends a signal throughout the supply chain. Consider on specific example, How does he work. Suppose one of the components for the production of any device is a 10-inch rod that comes on pallets. Let's say there are 100 rods on a pallet. When the pallet is finished, the assembly worker takes the card that was attached to the pallet and passes it to the core production area. After that, another pallet of rods is produced and sent to the instrument assembly shop. In essence, KANBAN is a pull model of production (from the English “pull” - pull), that is, each card, pallet, basket or box sent to a supplier or component manufacturer reflects the demand for the final product. Essentially, the KANBAN production planning system enables businesses to be reactive to customer needs instead of trying to predict the need.

1. JIT is an inventory management strategy and KANBAN is one of its elements.

2. KANBAN is a demand-based pull model of production, usually in the form of cards, baskets, pallets or boxes.

3. JIT uses KANBAN as a way to reduce inventory management costs. Together they make it possible to obtain "the right material, in the right place, at the right time and in the right quantities."

2.2.3 ORT micrologistics system

One of the most good examples Synthesis in the production of key elements of MRP and KANBAN based on modern information and computer technologies was the micrologistics system "Optimized Production Tehnology" developed in the early 1980s - ORT (optimized production technology).

The ORT system, developed by Israeli and American specialists, belongs to the class of "pull" micrologistics systems that integrate supply and production processes. The main principle of this system is to identify the so-called "bottlenecks" in the production process (in the original - critical resources). Many experts consider ORT to be a computerized version of KANBAN, with the difference that the ORT system prevents bottlenecks in the logistics network "supply - production", and the KANBAN system allows you to effectively eliminate bottlenecks that have already arisen.

The ORT system carries out automated operational and production planning and dispatching. Computer calculation of production schedules is performed per shift, day, week, etc. The tasks of controlling the shipment of stocks of finished products to consumers, searching for alternative resources, issuing recommendations for full-fledged replacements in the absence of the necessary material resources are also solved. When forming the production schedule, the following criteria are used: the degree of satisfaction of the production need for resources; resource efficiency; funds immobilized in work in progress; flexibility.

Implementation operational planning and regulation of production in the ORT system is carried out using software and mathematical software built on a modular basis.

To generate a production schedule from the ORT database, files of orders, technological maps, resources, sales forecasts, etc. are used. These files of materials and components are processed in parallel with the data of files of technological maps, as a result of which a technological route is formed, which is processed using software module A that identifies critical resources. As a result, it becomes possible to assess the intensity of resource use and the degree of their utilization and arrange them accordingly. At this stage, the technological route forks. The critical resource branch includes all bottlenecks and subsequent related logistic activities.

The effect of the ORT system from a logistical standpoint is to reduce production and transport costs, reduce inventories of work in progress, reduce the production cycle time, reduce the need for warehouse and production space, and increase the rhythm of shipment of finished products to consumers.

2.2.4 Total Quality Management (TQM)

The goal is to eliminate delays caused by product quality problems. Total quality management includes methods such as statistical control, quality circles and development technological process with foolproof. In TQM, each statement performs three additional actions. First, he checks the quality of the product received from the previous site. Then he controls the quality of his operation. And finally it checks again what it passes to the next one. In case there is a quality problem, the operator must stop the assembly line, and until the problem is solved, production will not resume. These three types of control are the Quality at the source method, which allows you to maintain high quality in production, as well as eliminate downtime at the workplace associated with waiting for inspectors. Thus, each operator is responsible for the "input control" of the products received from the supplier, and the "output control" of what he sends to his customer. This chain ends with an external buyer purchasing a high quality product.

Chapter 3. Practical application of the logical concept of JIT

3.1 Implementation of Just In Time

The Just in Time concept was developed at Toyota factories and is called the Toyota Production System (TPS). Based on the methods used in Ford's mass production, which was based on two main principles: the interchangeability of components and the principle of flow. The first principle made it possible to abandon highly skilled workers, replacing them with unskilled assemblers. The second principle, developed and implemented directly by Ford, was aimed at increasing production efficiency, reducing transportation time and manual labor by creating specialized ways of moving products - conveyors.

Toyota's goal was to adapt Ford's in-line production to meet limited resources and limited demand. As a result, two approaches to creating new system. The first approach was formulated by Taichi Ohno in 1988. In his opinion, the "fundamental doctrine" production system Toyota "becomes a complete elimination of losses." The second ideologue was Shigeo Shingo. For his part, he pointed to the need to organize a high value-added production flow and eliminate such types of waste as overproduction, downtime, transportation, excess inventory, unnecessary non-manufacturing operations and scrap, which reduce the value added in the production process. Together, these two approaches became the philosophical basis of Just in Time.

The implementation of Just in Time provides a number of benefits to increase the competitiveness of the organization. These include: reducing inventory levels, increasing productivity, improving the quality of products or deliveries, reducing delivery times, increasing the flexibility of the company, reducing the production cycle. A statistic report prepared by the US National Manufacturers Association in 1997 shows that among the 385 enterprises studied, the most successful were 16% that implemented the JIT system, and the survey confirmed the readiness of another 53% of companies to switch to this supply system. It is no coincidence that Ford, General Motors, Hewlett-Packard, Intel, Motorola and many others were among the pioneers of JIT in the United States. major manufacturers. It was the introduction of JIT that in many ways allowed these industrial giants to defend their market positions.

3.2 JIT example

The well-known American motorcycle company Harley-Davidson faced increased competition in the 1970s from Japanese companies: Honda, Yamaha, Suzuki and Kawasaki. Most of the previously stable companies in this industry have gone bankrupt. Four Japanese companies could deliver their motorcycles almost anywhere in the world with more high quality and at a lower price than competitors. In 1978, Harley-Davidson tried to prove in court that Japanese companies were selling motorcycles at dumping prices, i.e. below their cost. But during court hearings, it turned out that the operating costs of Japanese companies are 30% lower than those of Harley-Davidson. One of the main reasons for this state of affairs was their use of the JIT mode of operation. So in 1982, Harley-Davidson began developing and implementing a "materials as needed" program, similar to JIT. The company struggled initially, but over 5 years, it reduced changeover times by 75%, cut warranty and waste costs by 60%, and reduced work-in-progress by $22 million. During the same period, the company's productivity increased by 30% and the company is currently doing well in the market.

3.3 Application of the JIT system in Russia

For the first time, such a system was introduced in the aviation industry (MIC) of the USSR in 1940 with the participation of the new People's Commissar Shakhurin. Prior to this, as in other types of industry in the USSR, work was carried out according to monthly and quarterly plans. With such work, the first two weeks of each month usually went to "clean up" the unfinished last month, and in the last decade an assault began in order to somehow fulfill the plan. For the third decade produced about half of all products. This is at best. And at worst - the case dragged on even more. It was decided to stop this practice, introduce a daily schedule-norm for the delivery of products to the state and strictly adhere to it, since the assault slowed down the main production.

Similar Documents

Basic logistics concepts and systems. Micrologistics systems: KanBan, Just-in-time, MRP-1, MRP-2. Short description commercial activities LLC "Samson-K" Development of the company's logistics strategy based on the micrologistics concept.

thesis, added 12/22/2012

Studying the essence of logistics - strategic management(management) of material flows in the process of procurement, supply, transportation and storage of materials, parts and finished products. The essence, advantages, problems and disadvantages of the just-in-time concept.

abstract, added 04/09/2011

Theoretical aspects of the application of the Just-in-Time system, its main elements that are required for effective operation. An example of the practical application of the system in the American company Harley-Davidson. The concept of effective response to consumer requests.

abstract, added 02/04/2011

Information Support all elements of the logistics system, (supply, production and marketing). Purposes and meaning of information flows in the logistics system. Characteristics of modern information technologies logistics management in Russia.

term paper, added 11/15/2013

Logistics use of the term "just in time" in relation to industrial systems in which the movement of products in the production process from suppliers is carefully planned in time. Forming blocks, personnel and organizational elements of the system.

abstract, added 11/12/2013

The essence of the concept of "controlling". The main ideas of the Six Sigma concept system, its intellectual tools. The main elements that make up the quintessence of the Six Sigma system. Visual practical use six sigma quality concept.

term paper, added 11/10/2009

Description of pull and push logistics systems. The history of the emergence of the "just in time" production system. The goals and forming blocks of the system under study, consideration of examples of its application in production in practice. Experience of foreign manufacturers.

term paper, added 07/20/2012

The history of the development of managerial thought. Disadvantages and advantages of management theory for the implementation of competent management activities. Basic provisions, principles and ideas of modern management trends. The concept of "Lean production".

abstract, added 01/04/2016

Factors in the formation of logistics as a management concept and management tool. Fundamentals of the formation of the enterprise logistics management system, its main goals and improvement strategy. The problem of developing the commodity market infrastructure.

essay, added 09/15/2015

Development of the concept of the management system and substantiation of its effectiveness for the development of OAO Komkon. Enterprise history. Main activities. External environment factors: economic, political, market and technological. Goals of management.

Logistic concept "JUST-IN-TIME" (just in time)

The most widely used logistics concept in the world is the concept of "just in time" (just-in-time, JIT). It appeared in the late 1950s, when the Japanese company Toyota Motors, and then other automotive companies in Japan, began to actively implement the KANBAN micrologistics system. The name of this concept was given a little later by the Americans, who also tried to use this approach in the automotive industry. The original slogan of the concept of "just in time" was the potential elimination of stocks of materials, components and semi-finished products in the production process of assembling cars and their main units. The main idea of the JIT concept is as follows: if the production schedule is set (abstracting from demand or orders for the time being), then it is possible to organize the movement of material flows in such a way that all materials, components and semi-finished products will arrive in the required quantity, to the right place (on the assembly line - conveyor) and just in time for the production or assembly of the finished product. At the same time, insurance reserves that immobilize cash firms are not needed.

The ELA terminology dictionary defines the concept of "just in time" as an approach to success based on the gradual elimination of waste (waste refers to any action that does not add value to the product). It is also the delivery of materials at the right time and the right place.

The concept of "just in time" served as the basis for the subsequent introduction of logistics concepts/technologies such as "flat" or "lean" production and "value-added logistics".

From a logistical standpoint, the concept of "just in time" implies that the flows of material resources are carefully synchronized with the need for them, given by the production schedule for the release of finished products. Such synchronization is nothing more than the coordination of two basic logistics functions: supply and production management. This concept has been successfully applied in distribution, marketing systems for finished products and in macrologistics systems. With this in mind, the following definition can be given.

The concept of "just in time" is a modern concept / technology for building a logistics system in production (operational management), supply and distribution, based on the synchronization of the processes of delivering material resources and finished products in the required quantities by the time the links of the logistics system need them , in order to minimize the costs associated with the creation of stocks.

The concept of "just in time" is closely related to the components of the logistics cycle. Ideally, material resources or finished products should be delivered to a certain point in the logistics chain (channel) at the exact moment when they are needed, which eliminates excess stocks, both in production and distribution. Many modern logistics systems based on this approach are focused on short components of logistics cycles, and this requires an adequate response of the logistics system links to changes in demand and, accordingly, the production program.

The logistics concept "just in time" is characterized by the following main features:

- * minimum (zero) stocks of material resources, work in progress, finished products;

- * short production (logistics) cycles;

- * small volumes of production of finished products and replenishment of stocks (supplies);

- * relationships for the purchase of material resources with a small number of reliable suppliers and carriers;

- * effective information support;

- * high quality of finished products and logistics service.

The introduction and spread of the concept of "just in time" in the world has led to a change in the traditional management approach to inventory management.

The widespread use of the concept of "just in time" in logistics practice is explained by the low level of stocks of material resources, work in progress and finished products; reduction of production areas; improving the quality of products and reducing marriage; reduction of production time; increased flexibility when changing the range of products; high productivity and efficiency of equipment use; active participation of workers in solving production and technological problems; good relations with suppliers, etc.

Just-in-time goals are similar to the goals of a material requirements planning system - to provide the right part of the product at the right time in the right place, but the methods of achieving these goals and the results are completely different. While the material requirements planning system is built on calculations, the continuity system is built on industrial engineering. There are many distinguishing features systems "just in time", which are manifested in practice in any type of activity, in a company of any form of ownership, in the manufacturing or non-manufacturing sector of the economy.

Just-in-time implementation starts with how the product will be sold and whether it can be easily manufactured. If these questions are answered in the affirmative, attention switches to the development of the process itself.

The work of the logistics system, built on the principles of the "just in time" concept, can be represented as a two-bin inventory management system. One bunker is used to meet the demand in production or marketing, respectively, for material resources or finished products, the other is replenished as the first one is spent. Emphasis is placed on the placement of equipment in such a way as to ensure a continuous production process. Where possible, automation of both the production process and the processing of raw materials is being introduced. Often the equipment is placed in the shape of the letter U, which contributes to teamwork, flexibility of work, cyclical processing of raw materials and products. At the same time, product developers strive to standardize time cycles and the production of a constant set of products based on a monthly production plan throughout the system. This practice turns the production process into a cycle of at least a month.

Thus, the production of finished products in small batches for relatively short production cycles determines the duration of the supply cycles of material resources.

Theoretically, the ideal order size for a basic just-in-time system is one unit, however, this is typically not realized due to high marketing and processing costs per order.

Logistics systems that use the principles of the "just in time" concept are "pull" systems (pull systems), in which the placement of orders for the replenishment of stocks of material resources or finished products occurs when their number in certain links of the logistics system reaches a critical level. . At the same time, stocks are "pulled" through distribution channels from suppliers of material resources or logistics intermediaries in the distribution system.

In the "just in time" concept, demand plays a significant role, which determines the further movement of raw materials, materials, components, semi-finished products and finished products. The short components of logistics cycles in systems using this approach contribute to the concentration of the main suppliers of material resources near the company that carries out the process of production or assembly of finished products. The firm tries to select a small number of suppliers with a high degree of supply reliability, as any disruption in supply can disrupt the production schedule.

In the practical implementation of the "just in time" concept, product quality plays a key role. Japanese automotive companies, initially introducing the principles of this concept and the KANBAN micrologistics system into production, changed the approach to quality control and management at all stages of the production process and subsequent service. Ultimately, this resulted in the already mentioned philosophy of total quality management. The concept of "just in time" helps to strengthen control and maintain the level of product quality in the context of all components of the logistics structure. Micrologistics systems based on this approach, associated with the synchronization of all processes and stages of the supply of material resources, production and assembly, delivery of finished products to consumers, require the accuracy of information and forecasting. This explains, in particular, the short components of logistics (production) cycles. For effective implementation of JIT technologies, they must work with reliable telecommunication systems and information and computer support.

Dell at one time managed to rise largely due to the competent organization of the just-in-time system. At the beginning of his journey, Michael Dell decided to rely on direct sales, which allowed him to significantly reduce the company's costs. While the warehouses of other computer manufacturers were gathering thousands of components, Dell organized a system that made it possible to have only the necessary goods in stock. The assembly of the computer began only after its order.

As a result, Dell sold the computer cheaper than competitors, and could update the line of components much faster. For comparison, Dell started putting the Pentium 4 processor in its computers 85 days before HP did. It's just that the company's warehouses did not have such an abundance of unsold P3s.

What is the point?

Perhaps the Dell success story is the most famous and often mentioned when it comes to the concept of just-in-time deliveries. However, this concept was born not at all in the USA, but in Japan, like most modern technologies management related to lean manufacturing. Why in Japan? There may be several reasons. Firstly, the Japanese themselves are quite thrifty people. Their country is very limited in terms of natural resources, so these people are not accustomed to squandering materials. Secondly, it is worth paying attention to the culture of Japan. Here we are accustomed to trust the word. If a company has to deliver a product every day, then it will. There are no such frequent incidents and breakdowns as in the USA and Europe in Japan. And it wasn't. This is purely a cultural aspect.

So, what is the essence of the concept of just-in-time. Just-in-time is a system of supply of goods that allows the company to get rid of large warehouse stock. When using the just-in-time delivery system, a special schedule is drawn up, which indicates when and how much goods will be delivered. In this case, deliveries are often made daily. Obviously, the main advantage of such a system is its flexibility (example with Dell and Hewlett-Packard above) and the ability to reduce storage costs.

There is also a certain problem here. It is quite difficult to organize such a supply chain that will work without failures. After all, it turns out that when using just-in-time deliveries, the company begins to depend on its supplier. In the event of some unexpected problems on his side, the company will also suffer. You may even have to temporarily suspend production or sales of products. Finally, raising the price of transport costs may cause Just-in-time to be an inefficient system for any particular case. It is quite possible that it would be more profitable to store goods in a warehouse than to constantly deliver them (here it is immediately worth noting one more important point, why just-in-time deliveries originated in Japan - the distances in this country are much less than those that suppliers from Europe and America are forced to travel).

Today, Just-in-time is used not only in production, where the technology was introduced, but also in retail. At the same time, even small businesses may well use this system. True, not always and not everywhere. Everything here is very individual. You always need to calculate whether it is profitable for the company to use such a supply chain, or is it better to continue to stockpile. For example, in Russia, just-in-time deliveries have many problems, since according to statistics, our suppliers are far from being as obligatory as in Japan. However, this does not prevent domestic companies from successfully implementing this supply chain.

How it all began?

The just-in-time delivery system was given life by Toyota in the middle of the last century. It is believed that at that time there was a strong increase in the production of the company's cars. With the increase in production, a significant problem arose. The warehouses of the company accumulated great amount extra details. All the time I had to adjust the next delivery, and they took up space for nothing. Parts storage costs were on the rise. One fine day, the Japanese thought, how can this system be improved? So they came to the fact that they completely reorganized the entire supply chain in the company. Now all parts were supplied for each production area depending on how much the next one, who was the recipient of the manufactured part, demanded. Deliveries began to be carried out much more often, but at the same time, the warehouse had a minimum of goods necessary for current production. And nothing else.

With this system, Toyota increased productivity and was able to reduce inventory costs. The supply of goods as a whole was carried out so that the company could vary the scale of production within 10%. In addition, Toyota began to acquire shares in supplier companies. Of course, Japan is famous for its ability to keep one's word and keep promises, but it's much better to play it safe. That's what Toyota did.

After some time, the company further modernized the supply chain by introducing the kanban mechanism. My description of kanban was not the best. I will give a variant from the comments to this article from Dmitry Karpich:

"Kanban (canban - Japanese card) is technological maps production, reflecting the scheme for creating a product or service and actually used in this production. The "card" indicates how much, what and from whom is taken to obtain a "finished" (for a given site) product from the "raw materials" of "suppliers". Simply put, this is a recipe. This is not a production or supply plan at all (as I wrote earlier - note by the author of the article).

Kanban is required because of the specificity of the production process - the so-called "pull" production, when both the production task and the responsibility for the availability of resources fall on one shoulder. Compare with the soviet "but they didn't bring nuts to us, so there won't be tractors"!

Needless to say, this introduction has become revolutionary. The technology soon spread throughout Japan. And then (closer to the 80s) she will be interested in the USA and Europe. Today, Just-in-time deliveries are spread all over the world and are one of the most well-known concepts in logistics.

Advantages and disadvantages

Overall, just-in-time deliveries avoid the problem of overproduction, reduce inventories to the lowest possible level, and eliminate unreasonable warehousing costs. Such a system, among other things, allows you to organize production with a minimum of defects. Finally, in just-in-time deliveries, companies are always striving to increase the quality of their production, always looking for new ways that will allow them to work more efficiently. Let us list the advantages and disadvantages of such a supply chain point by point for clarity. The benefits include:

— Reducing the time of production of the final product;

— Reducing the cost of storing goods;

- Higher flexibility when changing a product (remember the Dell example at the beginning of the article);

- Higher productivity; - Reducing the time of preparation for production;

- Improved quality control; - More uniform production schedule;

– A minimum of optional work that relates to what takes place in the warehouse;

- Minimum disruption in production;

- Low probability of overproduction;

The disadvantages include: