The production structure of the enterprise includes divisions. The production structure of the enterprise and its elements. Production structure using the example of a repair company

Structure - this is a set of elements that make up the system and stable connections between them. An enterprise is a complex system, therefore, within an enterprise, depending on its goals, several interacting structures can be distinguished.

A modern industrial enterprise consists of: workshops, sections and farms, management bodies and an organization for servicing the enterprise’s employees.

Production units, units that manage the enterprise and serve its employees, the number of such units and units, their size and the relationship between them in terms of the size of occupied space, the number of employees and other characteristics represent the general structure.

Production divisions, units, and enterprises include workshops and areas where the main products of the enterprise, tools, and spare parts for equipment repair are manufactured. In some production units, repair work is carried out and various types of energy are generated.

The composition of the production divisions of the enterprise, their interaction in the process of manufacturing products, the ratio of the number of people employed in production, the cost of assets, the occupied area and their territorial location form a production structure , which is part of the overall structure.

There is no stable standard structure. It is constantly adjusted under the influence of production and economic conditions, scientific and technological progress and socio-economic processes. However, with all the variety of structures, manufacturing enterprises have the same functions, the main ones being the production and marketing of products.

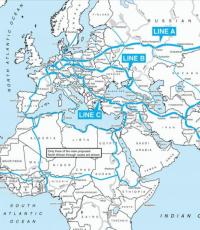

The structures of the enterprise reflect, first of all, the presence of main, auxiliary and service departments (Fig. 9.1).

Fig. 10.1. Company structure.

The production structure determines the principles of organization production process, such as continuity of the production process, rhythm of production, as well as the level of labor productivity, reduction of work in progress, efficiency of material and labor resources, quality of production.

The factors determining the production structure include:

Level of division of labor;

Level of specialization and cooperation of production;

The degree of competition in this and technologically related markets;

Level of development of technology, technology and production organization;

The nature of the products produced, the nomenclature, assortment and volume of production.

The production structure must ensure: proportionality of all divisions of the enterprise, compliance with the organizational structure, compliance with personnel potential. The production structure must be flexible and dynamic, because external environment constantly changing.

The formation of the production structure of an enterprise is the most important process in both organizational and economic aspects. To ensure normal functioning of the enterprise, there must be divisions that include workshops, sections, laboratories where the main products manufactured by the enterprise are manufactured, undergo inspections, tests, purchased components, materials, spare parts, etc. are located.

As a rule, the main structural unit the enterprise is shop - an administratively separate unit in which products (or part of them) are manufactured or a certain stage of the production process is performed. Many small enterprises have a shopless structure, i.e. consist of small production units - individual production sites or lines.

Shops are independent and full-fledged units and can be considered as centers of responsibility in financial structure enterprises.

In mechanical engineering, workshops can be divided into the following groups:

1. Basic

,

carrying out operations for the manufacture of products,

intended for implementation. These include procurement,

processing, assembly and testing.

2.

Auxiliary

- provide the main workshops with the necessary

tools, devices, carry out technical

maintenance and repair of technological equipment, etc. This

tool, model, repair shops, non-standard workshop

equipment, etc.

3. General plant service workshops and facilities

carry out

maintenance work for main and auxiliary workshops

transportation and storage of raw materials, semi-finished products, finished

products, energy transfer, etc. This group includes warehouses

divisions, transport, energy facilities, etc.

The main role in the production structure of the enterprise is played by design, technological departments, research departments and laboratories.

Shops also have an internal production structure, which refers to the composition of the production areas, auxiliary and service units located in them, as well as the forms of their production connections.

The next structural unit is production area. Production area - This is a structural unit united by a separate characteristic, representing a group of workplaces at which a relatively isolated part of the production process is carried out. The composition, number of sections and production connections between them determine the list of workshops and the production structure of the enterprise as a whole.

The primary link in the production structure of the enterprise is workplace - part of the production area where a worker or group of workers performs a separate operation to manufacture products or service the production process, using appropriate equipment and technological equipment. The nature and features of the organization of jobs influence the type of production structure. Workplace It can be simple (one worker services one machine), multi-machine (one worker services several pieces of equipment), complex (a group of workers service one unit).

The ratio between the main, auxiliary and service shops in terms of the number of workers employed in them, in terms of the production area occupied in them should reflect the priority importance of the main shops in the structure of the enterprise, since This is where all stages of the technological cycle of product manufacturing are carried out.

The production structure is formed during the creation of an enterprise, its reconstruction and technical re-equipment, and the development of new products.

Depending on the form of in-plant specialization and the level of cooperation at the enterprise, three types of production structure are distinguished:

1. Subject:

main workshops and their sections are built according to

production by each department of one or a group of products or

their parts. In this case, several are connected in one workshop

heterogeneous technological processes, focuses

various types of equipment. This type is typical for enterprises

large-scale and mass production.

Advantages: reducing and simplifying intra-factory cooperation, reducing the duration of the production cycle, increasing the responsibility of workers and managers for the quality of work, simplifying planning, using continuous production, high-performance equipment, and automatic lines. These advantages lead to increased productivity, increased output and reduced production costs.

2. With technological structure:

workshops specialize in

execution of certain homogeneous technological processes

(foundry, mechanical, assembly, etc.). They usually

The entire range of blanks or parts is manufactured. Or

products are assembled. With increasing scale of production

technological specialization is also deepening (shops of large,

medium and small castings, steel and non-ferrous castings, etc.). This structure is typical for small-scale production.

Advantages:

ease of production management,

the ability to quickly switch from one product range to

another.

Flaws: the complexity of intra-factory cooperation, significant time spent on reconfiguring equipment, limiting the possibility of using high-performance equipment, reducing the personal responsibility of managers and employees.

3. Mixed (subject-technological) production structure is characterized by the presence at the same enterprise of workshops or sections organized both on subject and technological basis (for example, procurement shops are organized on a technological basis, and assembly shops - on a subject basis).

Advantages: reducing the number of counter technological routes, reducing the duration of the production cycle, increasing the level of equipment utilization, and ultimately – increasing labor productivity and reducing the cost of products.

A rationally constructed production structure is most consistent with the organization of production, ensuring proportionality among all structures of the enterprise.

Changing the production structure affects the improvement of the technical and economic indicators of the enterprise, so it is necessary to determine ways to improve it.

The main ways to improve the production structure include the following:

Search and implementation of the perfect principle for building a production structure (for new enterprises) and using reserves for improving the structure (for existing ones);

Improving the plant layout;

Rational relationship between main, auxiliary and service departments;

Development of specialization, cooperation and combination of production;

Unification, standardization of processes and equipment.

One of the methods for improving the production structure is to bring it into line with the organizational and financial system enterprises. The main trend of improvement organizational structure is the transition from a linear-functional to a divisional and matrix structure, and for the production structure this will be expressed in the deepening of the financial independence of the production divisions of the enterprise. One of modern trends improvement of the production structure is the formation of flexible production processes that allow you to quickly respond to the introduction of new products.

PRODUCTION STRATEGY

Organization of production at an industrial enterprise

Production organizations– a set of forms and methods of rational combination of the main factors of the production process (people, tools ( processing resources) and objects of labor ( converted resources)) in space and time.

Decisions related to the organization of production are strategic in nature: they are made infrequently, are difficult and expensive, and have a long-term impact on the results of the production and economic activities of the enterprise. The development of the spatial and temporal organization of production should primarily be based on the strategic goals of a particular production. The set of such decisions is called production organization strategies. The production organization strategy refers to the strategic functions of PM in creating operating systems that supports a business organization in achieving its mission.

The production organization strategy determines: the production structure of a new or reconstructed enterprise; selection of forms and methods of organizing production processes within the enterprise; building work centers and providing them with resources.

Production structure of the enterprise and its elements

(building a production process in space)

Main principle - this is ensuring the minimum possible, according to technical and economic criteria, path of movement of objects of labor through the stages of the production process from raw materials and materials up to the output of the finished product.

The combination of parts of the production process in space provides production structure of the enterprise, which is understood as the totality of production units of an enterprise that are part of it, the order of their spatial placement, as well as the forms of their interrelations. It determines the division of labor between its production units, i.e. in-plant specialization and production cooperation.

The production structure of an enterprise should not be confused with general structure of the enterprise(composition of an industrial company) (Fig. 1).

Fig.1. General structure enterprises

Factors that determine the nature of the production structure of an enterprise, the composition of its workshops and services: 1) the nature (design) of the product; 2) stability of the nomenclature; 3) manufacturing program; 4) features of technological processes; 5) degree of unification; 6) level of specialization and cooperation.

Figure 2 shows a diagram of the relationships between factors that determine the production structure of an enterprise.

The enterprise is characterized by the identification of elements of the production structure of four levels:

enterprise → workshop/farm → site/department → workplace

The main element of the production structure of the enterprise (main structural unit) is shop, with a shopless enterprise structure – production area.

Fig.2. Relationships between factors that determine the production structure of an enterprise

Shop- this is a technologically and organizationally separate production unit that performs a certain part of the enterprise’s production process (partial production process) and has administrative independence. In turn, the workshops have complex structure. The main element of the production structure of the workshop is plot, production structure of the site - workplace.

Production site is a technologically and organizationally separate group of jobs that have a certain specialization and are united according to certain characteristics. Based on the master's controllability norm of 20-25 workers per shift, the production site is allocated as a separate administrative unit of the workshop.

In accordance with the purpose of partial production processes implemented within the workshops, there are main and auxiliary workshops serving workshops and farms industrial purposes. Main workshops manufacture the main (commercial) products of the enterprise.

Since the main process of the total production process is divided into procurement, processing, assembly and testing phases (stages), in accordance with the stages of the main production process there are distinguished main production workshops: procurement, processing and assembly.

The approximate composition of the main and auxiliary workshops serving the farms of such an enterprise (with the technological specialization of the workshops) is presented in Table 1.

Table 1

Composition of main and auxiliary workshops serving farms

machine-building enterprise

| Subdivision | Purpose |

| I. Main workshops | Production of main products |

| Procurement shops | Receiving blanks various types |

| Foundries (gray cast iron, malleable cast iron, steel casting, non-ferrous casting) | Receiving castings |

| Forging (press-forging, forging-stamping) | Receiving forgings and stampings |

| Nesting, cutting and straightening of metal (blanks) | Receiving blanks from rental |

| Metal structures | Receiving welded workpieces |

| Processing shops | Performing various types of processing |

| Mechanical | Mechanical restoration |

| Cold stamping | Cold stamping |

| Thermal | Heat treatment |

| Metal coatings (electroplating, painting) | Application of protective and decorative coatings |

| Assembly shops | Performance assembly work various types |

| Partial and general assembly assemblies | Assembly of individual assembly units and general assembly |

| Assembly and welding | Carrying out assembly and welding work |

| Assembly | Carrying out installation and commissioning work |

| Test | Testing of individual units and finished machines |

| Painting of finished cars | Finished car painting |

| Options and packaging | Assembling and packaging of products ready for shipment |

| II. Auxiliary workshops | Production of auxiliary products |

| Tool shops | Manufacturing, repair and restoration of technological equipment |

| Pattern shop | Manufacturing and repair of models for foundries |

| Container shop | Manufacturing and repair of containers for packaging finished products, returnable and reusable containers for non-production and intra-production circulation |

| Experienced workshop | Production of prototypes of new products or individual units, their models or layouts |

| Electrode shop | Manufacturing of electrodes for electric arc welding of metals |

| Repair shops | Carrying out various types of repair work |

| Mechanical repair | Repair of equipment and production of spare and replacement parts for it, modernization of existing and production of non-standard equipment, including means of mechanization and automation of production |

| Electrical repair | Repair of electrical equipment in all workshops of the plant, production of spare and replacement parts |

| Repair and construction | Repair of plant buildings and structures |

| Energy workshops | Obtaining various types of energy carriers |

| Compressor | Obtaining compressed air for pneumatic devices and tools, sandblasters and spray guns, blowing molds and parts |

| Oxygen | Obtaining oxygen for gas cutting and welding of metals |

| Acetylenic | Production of acetylene for gas cutting and welding of metals |

| Gas generating station | Receiving from solid fuel gas burned in industrial furnaces (forging, thermal, etc.) |

| Boiler room | Production of steam for technological purposes (heating drying chambers, heating water in washing machines), for heating buildings and heating air in ventilation devices |

| III. Service farms | Provision of production services |

| Storage facilities | Storage, accounting, assembly and issuance of material assets |

| Energy economy | Unites devices designed for transformation and distribution of electricity, supplying production with steam, compressed air, gas and liquid fuel (step-down substations, transformer stations in workshops, electrical networks; steam pipelines, air pipelines, gas pipelines, oil pipelines; communications and alarms). Energy facilities and energy shops, which can be combined into one energy (or steam power) shop, form a single energy service of the plant |

| Transport industry | Transportation of goods arriving at the plant and leaving the plant, transportation of goods within the plant between workshops and warehouses, as well as loading and unloading operations. It includes depots, garages, repair shops, track facilities, transport and loading and unloading facilities |

| Sanitary Engineering | Creation of necessary production and sanitary conditions in workshops. Combines water supply, sewerage, ventilation, heating systems and networks |

| Central Factory Laboratory | Control testing of materials, semi-finished and finished products, quality control of technological processes, research work and implementation of their results in production. It consists of a number of laboratories (departments) serving the plant: mechanical, metallographic, chemical, pyrometric, X-ray, etc. Branches of the laboratory (express laboratories) are created in foundries and thermal shops |

Depending on the presence of procurement, processing and assembly shops in the main production of the enterprise, one can distinguish five basic types of industrial structure:

Machine-building enterprises can specialize in performing only one phase of production or in performing several phases of production. Industrial enterprises with a full technological cycle have the most complex production structure. Similar types of production structure are typical for workshops.

For illustration, Fig. 3 shows a typical production structure industrial enterprise, implementing the full integrated cycle of product manufacturing.

Fig.3. Typical production structure of a plant with a full technological cycle

7. Production process and types of production

7.3. Production structure of the enterprise

Production structure An enterprise is a set of production units of an enterprise (shops, services) that are part of it and the forms of connections between them. The production structure depends on the type of product and its nomenclature, the type of production and forms of its specialization, and on the characteristics of technological processes. Moreover, the latter are the most important factor, which determines the production structure of the enterprise. A production structure is essentially a form

Characteristics of types of production according to the organization of the production process. It distinguishes production divisions:

- basic,

- auxiliary,

- serving.

In the workshops (divisions) of the main production, objects of labor are transformed into finished products. Workshops (divisions) of auxiliary production provide conditions for the functioning of the main production (tools, energy, equipment repair). Service production divisions provide main and auxiliary production with transport, warehouses (storage), technical control etc.

Thus, the enterprise is divided into main, auxiliary and service workshops and production facilities.

In turn, the main production shops (in mechanical engineering, instrument making) are divided into:

- for procurement;

- processing;

- assembly.

Procurement shops carry out preliminary shaping of product parts (casting, hot stamping, cutting blanks, etc.)

IN processing shops Parts are processed mechanically, thermally, chemical-thermal, galvanically, welding, paint and varnish coatings, etc.

IN assembly shops assemble assembly units and products, adjust them, set them up, and test them.

Based on the production structure, a master plan of the enterprise is developed, i.e. spatial arrangement of all workshops and services, as well as paths and communications on the territory of the plant. At the same time, the direct flow of material flows must be ensured. Workshops must be located in the sequence of the production process.

Shop- this is the main structural production unit of an enterprise, administratively separate and specializing in the production of a certain part or products or in the performance of technologically homogeneous or identical-purpose work. Shops are divided into sections, which represent a group of workplaces united according to certain characteristics. The production structure of the workshop is shown in Fig. 7.2.

Figure 7.2. Production structure of the workshop

Workshops and sections are created according to the principle of specialization:

- technological;

- subject;

- subject-closed;

- mixed.

Technological specialization based on the unity of the applied technological processes. This ensures high equipment utilization, but makes operational and production planning difficult, and lengthens the production cycle due to increased transport operations. Technological specialization is used mainly in single and small-scale production.

Subject specialization is based on concentrating the activities of workshops (sections) on the production of homogeneous products. This allows you to concentrate the production of a part or product within a workshop (site), which creates the prerequisites for organizing direct-flow production, simplifies planning and accounting, and shortens the production cycle. Subject specialization is typical for large-scale and mass production.

If a complete production cycle of a part or product is carried out within a workshop or site, this division is called subject-closed.

Shops (sites) organized according to the subject-closed principle of specialization have significant economic advantages, since this reduces the duration of the production cycle as a result of the complete or partial elimination of counter or return movements, reduces the loss of time for equipment readjustment, simplifies the planning system and operational management progress of production.

| Previous |

Modern enterprises are a collection of departments with different types of activities, interconnected by a single process of manufacturing products or providing services.

Many enterprises carry out all stages life cycle products: pre-production, production and post-production. In particular, the pre-production stage includes the experimental design development of a new product, marketing market research, the production stage - its manufacture, and the post-production stage - the sale of the product. All this expands the composition of the enterprise’s divisions, complicates the connections between them and places high demands on the organizational and economic justification of the production structure, that is, on rational organization functioning and location of each production unit, to establish close production connections between workshops and areas.

Production structure of the enterprise - this is a spatial form of organization of the production process, which includes the composition and size of the production divisions of the enterprise, the forms of their relationships with each other, the ratio of divisions by capacity ( bandwidth equipment), the number of employees, as well as the location of departments on the territory of the enterprise.

The production structure of the enterprise reflects the nature of the division of labor between individual departments, as well as their cooperative connections in a single production process for creating products. It has a significant impact on the efficiency and competitiveness of the enterprise. The composition, size of production units, the degree of their proportionality, the rationality of placement on the territory of the enterprise, the stability of production relations affect the rhythm of production and the uniformity of product output, determine production costs and, consequently, the level of net income of the enterprise. Therefore, an effective production structure of an enterprise must meet the following requirements:

- simplicity of the production structure (sufficient and limited composition of production units);

- absence of duplicate production units;

- ensuring the direct flow of the production process based on the rational placement of units on the plant territory;

- proportionality of the capacity of workshops, sections, equipment throughput;

- stable forms of specialization and cooperation of workshops and sections;

- adaptability, flexibility of the production structure, that is, its ability to quickly restructure the entire organization of production processes in accordance with changing market conditions.

Distinguish two types of production structures:

1. Complex production structure (multistage). With it, the enterprise has all stages of the production process: procurement, processing and production.

2. Specialized (1-2-stage) production structure, in which one or two stages are missing. The production process at the missing stages is provided in the form of cooperative supplies from other enterprises.

Elements of production structure

The primary element of the production structure is the workplace - this part of the production area of a workshop, equipped with main equipment and auxiliary devices, objects of labor, serviced by one or more workers. Part of the production process is performed at the workplace; several part-operations can be assigned to it.

Types of jobs:

- simple workplace (one piece of equipment, one worker);

- multi-machine workplace - one worker services several types of equipment (usually operating in automatic mode);

- complex workplace (typical for continuous production processes) - one unit or installation is serviced by a team of workers.

Depending on the assignment of the production area to a workplace, stationary and mobile workplaces are distinguished. Mobile jobs include categories of workers such as adjusters, repairmen, and transport workers. They are not allocated production space.

According to the level of specialization, workplaces are divided into specialized (a workplace is assigned to perform three to five detail operations) and universal (detail operations are either not assigned, or their number is quite large - more than 20).

The set of workplaces at which technologically homogeneous operations or various operations for the manufacture of one or two types of products are performed constitutes a production site.

Plots are created according to two principles:

1. Technological. The site consists of the same type of equipment (a group of lathes, a group of milling and drilling machines); workers on site perform a certain type of operation. There is no assignment to workplaces for the production of certain types of products. This type of site is typical for small-scale and single types of production organization.

2. Subject-closed. At such a site, various types of equipment are used, which are located along the technological process. Workplaces specialize in the manufacture of a certain type of product (parts). The site employs workers of various specialties. A variation of this type of section are production lines. This type of site is typical for large-scale and mass production; its operation is more efficient compared to a site created according to a technological principle.

Several production areas are combined into workshops. A workshop is an administratively separate part of an enterprise, specializing either in the manufacture of products or parts of them, or in performing a certain stage of the production process. Headed by the head of the workshop.

1) basic - production of the main core products or a completed part of the production process. According to the stages of the production process, the main workshops are divided into procurement, processing and production;

2) supporting - production of products auxiliary for their intended purpose for the main workshops (tool shop, repair shop, energy sector, construction shop);

3) servicing - provision of production services to both the main and supporting workshops (transport facilities, energy facilities, construction shops);

4) experimental - production and testing of mock-ups and prototypes of new types of products being designed;

5) auxiliary and collateral. Ancillary workshops include workshops that extract and process auxiliary materials, for example, a quarry for the extraction of molding earth, peat mining, a refractory workshop that supplies the main workshops with refractory products (at a metallurgical plant). Ancillary workshops also include workshops for the production of containers for packaging products. Side shops are those in which products are made from production waste, for example, a consumer goods shop. IN last years the share of these workshops in the production structure has increased significantly;

6) auxiliary — cleaning the factory area, growing agricultural products.

Depending on the type of specialization, the following types of production structure of the main workshops are distinguished:

- technological;

- subject (or component-assembly, if the enterprise specializes in the production of parts or assemblies for products);

- mixed (subject-technological).

In workshops with technological specialization, a certain part of the production process is performed. The products produced by the workshop change frequently and are not assigned to work stations. This kind industrial structure least effective compared to subject and detail-node.

The main disadvantages of the technological structure include:

- high labor intensity of products and low efficiency of resources used, and therefore high production costs;

- large losses of time for frequent readjustment of equipment, transport work to move objects of labor from one site to another, large losses of time for inter-shift and inter-operational maintenance of parts and semi-finished products. This entails a high production cycle time for the product and low turnover. working capital and, consequently, relatively low production profitability.

The subject or component-unit structure of the main workshops is typical for the mass production of products of a stable range; with this type of production structure, each workshop specializes in the production of one or several structurally similar products. In workshops, sections are created according to a subject-closed principle.

Advantages of the subject structure compared to the technological structure:

- it promotes the introduction of progressive, high-performance specialized equipment (automated production lines, flexible production systems);

- planning is simplified, as well as inter-shop and intra-shop cooperation;

- production cycles for manufacturing parts and assemblies are shortened;

- the responsibility of workshop and site workers for product quality and fulfillment of the nomenclature plan increases;

- Labor productivity increases, other economic indicators of workshops and the enterprise as a whole improve.

The most common is a mixed structure (subject-technological). Under it, procurement shops have a technological structure, processing shops have a component structure, and production shops have a subject structure.

In changing market conditions, the subject structure becomes more vulnerable. A way out of this situation can be the process of diversification of production (expanding the production of various types of products and implementing new types of activities). This is achieved through the widespread use of standardization and unification of the design of manufactured products and, on this basis, increasing the flexibility of the production structure.

A production unit as an element of the production structure is a complex of specialized workshops that have an independent management structure (but do not have the right legal entity). A production unit is created in very large enterprises, holding companies, concerns; can operate as a branch (subsidiary JSC) while maintaining legal independence.

The figure shows the production structure of a furniture factory.

|

Main workshops |

Auxiliary workshops |

Service shops |

Auxiliary and side workshops |

|

|

Procurement |

Processing and assembly |

|||

|

Chipboards (chipboards) |

Cabinet furniture |

Instrumental |

Transport |

|

|

Cutting |

Upholstered furniture |

Energy |

Storage facilities |

Kitchen furniture |

|

Fittings |

Highly artistic furniture |

Building |

||

|

Carpentry |

Repair |

|||

Factors influencing the nature and features of the structure of enterprises

Production enterprise structures are very diverse. However, we can identify the following set of factors influencing the nature and characteristics of a particular structure.

1. Industry affiliation of the enterprise

It is determined both by the nature of the production process and by the design features and purpose of the manufactured product. This factor primarily influences the composition of the main workshops of the enterprise, which will differ significantly in different industries. Thus, a single-stage production structure is typical for extractive industries, a multi-stage one for manufacturing industries.

For example, in the metallurgical industry, the main production shops include: blast furnace, open-hearth or converter production, and a rolling shop. In mechanical engineering - foundry, forging, machining, assembly shops. For the textile industry: spinning, weaving, dyeing and finishing shops.

Auxiliary workshops will be (taking into account some features) identical in all industries, so the industry affiliation of the enterprise has almost no effect on their composition and organizational features.

2. Nature of the production process (analytical, synthetic, direct) influences the level of development and diversity of the main stages of the production process represented at the enterprise: procurement, processing, production.

At analytical production process, when several types of finished products are produced from one type of raw material, enterprises may have one or two procurement shops and several production shops. In this case, the problem of organizing sales of products that are diverse in nature becomes relevant. This structure is typical for enterprises in the chemical, metallurgical, light, and food industries.

Enterprise use synthetic The production process, on the contrary, involves the creation of several procurement shops and a limited number of production shops. This type of production structure is typical for machine-building enterprises and furniture factories. For example, an automobile plant has foundries, forging and press shops, and production conveyor lines for assembling several models of cars. For the production structure of these enterprises, the problem of organizing logistics and importing a large range of material resources and purchased semi-finished products becomes very relevant.

The direct production process is used in extractive industries: mines, mines, quarries. Their production structure may have one or two procurement workshops (extraction of raw materials, their enrichment) and one production workshop - small processing of raw materials and shipping to consumers.

3. Design and technological features of the product

Requirements for product quality have a significant impact on the nature of the production structure of the enterprise. For example, in the production of science-intensive high-precision equipment (radio electronics, electrical engineering, machine tool building, aircraft industry) in the production structure, a significant share in the number of workers employed in them is occupied by departments serving the pre-production stage: scientific and technical centers, laboratories, experimental workshops, testing stations, subdivisions for supervision of installation, adjustment and service of their products to consumers. Communications at these enterprises are quite complex. Their production structure is subject to high requirements for flexibility and adaptability. This is primarily due to the high rate of product renewal and the constant development of new types of products.

4. Production scale

The size of the enterprise has a significant impact on the composition and size of production units. The larger the enterprise, the more complex and expensive its production structure, the more diverse the composition of its elements: sections, workshops, production units, as evidenced by the table.

Composition of production units in small, medium and large enterprises

|

Division name |

Enterprise sizes |

||

|

small |

average |

large |

|

|

Production unit |

|||

|

Workplace |

|||

As can be seen from the table, the most complex structure is large enterprises, where there is a 4-level production structure. Production unit- a medium-sized enterprise, consisting of several specialized workshops, which, in turn, consist of sections and workplaces.

The production structure of a small enterprise can be shopless, consisting only of sections and workplaces.

5. Nature of specialization

This factor influences such types of production structure of the main workshops as subject, part-unit, and technological. The choice of one or another form of production structure is determined by the scale of production of the same type, structurally similar products of a stable range.

The subject form of specialization of the production structure is associated with the production of finished finished products by one or more workshops. This type of structure is used in the mass type of production organization. Products of workshops with a component-assembly form of specialization - parts or assemblies for finished products. This type of production structure is also used in high-volume and mass production types, usually in machining shops. Under the conditions of the technological form of specialization, workshops are assigned only the execution of technological processes. The products are varied; there is no fixed product range at the workplace. This form of specialization of the production structure is typical, as a rule, for procurement shops. Compared to the subject and component-node forms of specialization, this form of production structure is the least effective.

Forms of cooperation are also directly related to the forms of specialization of the production structure. The higher the level of specialization, the broader production connections are established between workshops within the enterprise and with external suppliers of material and production resources.

The specialization of the production structure determines its type (specialized or complex). With a specialized production structure, one or two stages of the production process may be missing, and the plant in this case operates as a machine assembly or assembly shop, receiving all the necessary components for the manufacture of products from outside. The complex production structure has a full complement of workshops, both main and service.

6. Scientific and technological progress

Scientific and technological progress has a dual impact on the production structure of an enterprise.

On the one hand, due to the increasing complexity of manufactured products and high requirements for their quality, the production structure of the enterprise is becoming more complex. It includes divisions related to the scientific and technical preparation of production: laboratories, experimental workshops specializing in the development of new types of products.

In addition, scientific and technical progress causes obsolescence of manufactured products and used equipment, which places additional demands on the production structure in terms of its flexibility, adaptability and, therefore, significantly expands the scope of work on its restructuring.

On the other hand, the implementation of scientific and technical progress leads to a simplification of the production structure. For example, the introduction of precision casting methods significantly reduces labor costs for subsequent machining of parts and simplifies the production structure of machine shops. Integration of production processes based on the use of numerically controlled machines, aggregate multi-position machines, and production lines excludes areas with traditional types equipment and simplifies their structure.

Thus, the nature of the production structure is determined by the characteristics of the enterprise itself, its industry, size, degree of specialization and cooperation. When developing a production structure, it is necessary to take into account all of the above features.

E.S. Vasilyeva Ph.D. econ. Sciences, Associate Professor REA named after. G.V. Plekhanov

Production structure of the enterprise– these are all production units in the aggregate (services, workshops), as well as types of relationships between these elements. It is influenced by the type and range of manufactured parts, the type and forms of production specialization, and the features of technological processes.

At the same time, it is precisely technological processes are the most important parameter on which the entire production structure of the enterprise organization depends.

Structure production activities enterprise is determined by a number of factors that are considered important economic indicators. We are talking, in particular, about the quality of manufactured goods, the growth of labor productivity, the amount of production costs, the efficiency of distribution and use of resources.

The production company performs key functions:

- takes care of the logistics of the production process;

- organizes and manages the work activities of employees in the company;

- produces products for industrial and personal use;

- complies with applicable standards, state laws, regulations;

- sells and supplies goods to consumers;

- services products during the after-sales period;

- takes care of the comprehensive development and increase in production volumes;

- pays taxes, makes mandatory and voluntary payments and contributions to the budget and other financial authorities.

The production organization itself decides how to distribute and use the goods produced, the resulting profit remaining after deducting taxes and other obligatory payments.

Quite often in the modern world, new companies appear and existing ones expand. These processes are greatly influenced by the following factors:

- unmet demand for goods, works and services is the most important parameter; if the products produced by the enterprise turn out to be unclaimed, the consumer does not want to buy them, and the costs of the production process do not pay off, the company may go bankrupt;

- the resources that a company needs to produce a product are, first of all, the availability of a production base and raw materials;

- the corresponding stage of development of science and technical means in a given production industry.

Production organizations, together with their teams, are the main links in the formation of a chain of sectoral and territorial complexes, the formation of departments and ministries. In the national economic complex manufacturing companies- main elements.

In accordance with the law of the Russian Federation, an enterprise operating in the production sector is fully responsible for its activities and all processes occurring in it. The organization’s activities should not interfere with the normal operation of other companies or negatively affect the living conditions of people living in nearby areas.

Let us note that government authorities do not have the right to interfere with the implementation of the administrative and economic functions of the company. Government authorities can only control how lawfully a company carries out economic activity, propose various solutions and demand that management follow current legal standards.

The production structure of an enterprise varies. However, all manufacturing companies essentially perform the same job - produce and sell goods.

The structure of the enterprise’s production system for normal functioning must consist of:

- governing bodies;

- functional departments, laboratories, other non-production services;

- main production workshops;

- auxiliary and service warehouses and workshops;

- other organizations (social welfare, auxiliary).

The direction of work, scope of activity and production volumes in the company are determined by the composition, technological profile, scale of workshops, areas, workshops where the production process is carried out.

During production, products go through several stages. Each stage is technologically homogeneous work, and it is they that are the basis for dividing production into various processes. Specialists of different profiles and qualifications are responsible for each process.

Why a company is doomed if it doesn't have a mission

The more closely it is related to the type of activity of the company, the more effective the mission. For example, the mission of Google in the early stages of its development was: “Organizing the world’s information, providing universal access to it and the rights to use it.” The company was solving exactly this problem, so this mission served as its true guide.

Find out how to choose the strategically correct mission for your company in the article electronic journal"CEO".

Composition of the enterprise's production structure

Every manager is interested in ensuring that the production and production structure of the enterprise are successful. The organizational and production structures of the enterprise must be built intelligently. The quality of its activities depends on this, among other things.

The rational design of the production process is very important here. This can be achieved by identifying the most efficient production structure, without forgetting about the characteristics of the company.

What are the characteristics of the enterprise's production structure? The structure of a company is the ordered and interconnected elements in the aggregate. The relationship between them is stable, ensuring the functioning and development of the components as a single structure.

The production structure of the enterprise includes basic elements in the form of workshops, sections and workplaces.

Types of production are distinguished by how the production process is organized. Here we can mention the following production departments:

- basically;

- auxiliary;

- serving.

A workshop is a key production unit, administratively separated, specializing in the production of certain components, parts, or carrying out work that is identical in purpose or technically homogeneous.

There are always several sections in the workshops. Such areas are workplaces grouped according to a certain characteristic.

The workshops are divided into auxiliary and main production units. Auxiliary workshops are designed to provide conditions for the normal operation of the main ones. As for the main ones, there the products are turned into goods ready for sale.

There are also service workshops that provide the above (main and auxiliary) vehicles, warehouses and technical support.

That is, the production structure of the enterprise consists of main, auxiliary, service units and production facilities.

There are 2 groups of production departments (workshops, sites).

1. Main production workshops, where products are directly manufactured for sale. The formation of main divisions is carried out in accordance with the company profile. The formation process is also influenced by specific types of goods, scale and production technologies.

The main tasks of the main workshops are: manufacturing products within precisely specified deadlines, reducing production costs, improving the quality of goods, finding and applying solutions for the rapid restructuring of the production process in connection with the changing market situation and customer needs. The solution to all these problems is facilitated by rational specialization and placement of workshops, their cooperation and ensuring proportionality of the production process from the first to the last operation.

Workshop specialization can be:

- subject-specific (the main part or the entire production process for creating certain types of finished products is concentrated in separate workshops);

- sub-detail (unit-by-unit) (each production unit is assigned the production of individual components);

- technological (stage) (each workshop is responsible for a certain stage of production);

- territorial (divisions remote from each other carry out the same work).

The main workshops can be:

- procurement;

- processing;

- assembly

The tasks of the blank shops include the initial shaping of products (such departments, among other things, make up the production structure of the enterprise; divisions cut blanks, do stamping, casting and other similar work).

Processing shops perform mechanical, thermal, chemical-thermal, galvanic processing of parts, weld them, varnish them, etc.

The tasks of assembly shops are assembly, regulation, adjustment, testing of components from which the finished product is subsequently assembled.

2. Auxiliary and service workshops, whose main task is to service production processes and solve various problems directly within the company.

The main task of auxiliary workshops is to create all conditions for a continuous work process in the main production.

Auxiliary are workshops and production areas that:

- manufacture, repair, configure instruments, fixtures, and equipment;

- control the operation and repair of equipment, monitor mechanisms, structures, buildings;

- provide heat and electricity supply, supervision and repair electrical equipment and heating networks;

- transport raw materials, materials, workpieces, finished products inside and outside the enterprise;

- store products (warehouses).

The structure of the enterprise's production activities serves as the basis for the development of a master plan, that is, the production location of services and departments, communications and routes in the plant. Let us note that it is very important to ensure the direct flow of material flows. The location of the workshops must correspond to the production stages.

Types of enterprise production structure

If the company operates in the industrial sector, the production structure may be:

- subject;

- technological;

- mixed (subject-technological).

In an enterprise with a subject structure, new main workshops and their sections are built according to the following principle: each department is assigned responsibility for the manufacture of a particular part or a certain group of spare parts.

As a rule, the subject structure is preferred to be used by assembly and mechanical assembly shops of factories that produce products in large volumes or products in large series.

An example of such a structure in a car production enterprise is workshops that produce chassis, engines, gearboxes, and bodies; at a plant for the construction of machine tools - workshops that produce spindles, shafts, body parts, beds.

If we are talking about a shoe manufacturing company, an example of a division where the subject structure of production activities is applied is the welt shoe workshop, etc.

The subject structure has many serious advantages. The main advantages are to limit the form of communication between production departments, shorten the paths for moving components, simplify and reduce the cost of inter-shop and shop transport, reduce the duration of the production cycle, and increase the responsibility of specialists for the quality of work.

As part of the subject structure, workshops are equipped necessary equipment during the technological process, and in the manufacture of products they use machines, stamps, tools, and devices with high productivity. Thanks to all the measures listed above, the enterprise’s production volumes are increasing, and the cost of manufactured parts is decreasing.

The technological production structure of the enterprise presupposes a clear division along technological lines. So, at a plant with such a structure there is a foundry, mechanical, assembly, forging and stamping shops - that is, all departments are technologically separated from each other. Thanks to the creation of this structure, managing a site or workshop becomes much easier, as well as distributing specialists and restructuring production from one product range to another.

The technological production structure of the enterprise also has disadvantages. Thus, counter routes for the movement of components may arise, production connections between workshops may become more complicated, and costs for equipment readjustment may increase.

In addition, with such a structure, it is quite problematic to use high-performance special machines, tools and devices. Because of all this, labor productivity increases at a low rate, and the cost of products decreases.

A mixed (subject-technological) structure presupposes the presence at one enterprise of main divisions, the principle of organization of which is both subject and technological.

For example, the structure of procurement shops (forging, foundry, pressing) is usually technological, while mechanical assembly shops are subject-specific.

As a rule, companies with a mixed structure operate in the fields of mechanical engineering, light industry (furniture, footwear, clothing organizations) and in some other areas. Production built on this principle has a number of advantages. Transportation within workshops is carried out less frequently, the duration of the production cycle of products is reduced, labor productivity increases, and the cost of parts is reduced.

It is very important in what sequence the enterprise performs actions in the external and internal environment. His activity as a whole depends on this. Here it is necessary to consider time series, that is, the time values of the company’s access to the sources of its activities, and indicators on the basis of which one can judge the organization’s place in the market environment. To better understand how things are going today, you should compare the company’s indicators with the indicators of similar companies that are successfully operating at the moment. It is also necessary to record what the structure of the enterprise’s production activities is. The sequence of economic activity of the organization depends on this.

The company's economy should be formed as an economy of individual complex elements, if we consider this process from a structural point of view. How proportionally the links should relate to each other depends on the ratio production capacity workshops and areas combined for the purpose of manufacturing the final product.

The mixed (subject-technological) structure of production activity is increasingly used in enterprises, which allows saving living and material labor, using materials and raw materials in an integrated manner, and distributing financial resources most efficiently.

With the design and technological homogeneity of products, favorable prerequisites appear for deepening the company’s specialization, as well as for automated and continuous production of goods.

An important role in the structure of the enterprise is given to inventories that support the production process. Thanks in part to them, the organization functions. That is, if during production a shortage of certain materials or raw materials is discovered, productive reserves compensate for the shortfall. This contributes to the formation of a closed production cycle.

The primary link in organizing the production process is the workplace. This is an integral and key, inseparable part of the production process, which is served by one or more employees.

The company's performance indicators are largely determined by how jobs are organized and located in departments, how justified their number and specialization are, and how coordinated their interactions are.

Structure of production processes at the enterprise

When production specialists are assigned to jobs, groups, services or brigades are usually formed. The creation of teams is carried out with the aim of solving problems that involve joint activities.

A team may consist of workers with different qualifications, different professional areas and skills. Composition, like organizational form team, which can be complex or specialized, is determined by the nature, complexity and features of the production process, as well as the labor intensity of the work.

Groups, units, brigades form sectors and sections, and these, in turn, are connected into departments, workshops and laboratories. The last three elements form the structure of the organization.

The workplace at the enterprise is organized taking into account the characteristics of the production process and the type of work performed. The specialist’s workplace must fully comply with ergonomic and technical standards. Here is everything the employee needs, everything he needs in the process labor activity. The specialist spends most of his working time there.

The production cycle is the calendar period during which raw materials, workpieces or other processed products go through all stages of production or a certain stage of it, becoming finished products. The production cycle is expressed in calendar days or hours (if we are talking about low labor intensity of the product).

The most effective form of organizing production from an economic point of view is the continuous production process. The flow form of production is characterized by the following features:

- one or a limited number of product names are assigned to a specific group of workplaces;

- technological and auxiliary operations are rhythmically repeated in time;

- jobs are specialized;

- workplaces and equipment are located along the technological process;

- Special vehicles are used for interoperational transfer of parts.

Flow production and the production structure of the enterprise involve the implementation of such principles as:

- rhythm;

- parallelism;

- specialization;

- proportionality;

- straightness;

- continuity.

In continuous production, the highest labor productivity, reduced production costs and a shortened production cycle are observed. The basis (primary link) of continuous production is the production line.

When production lines are designed and organized, indicators are calculated, work schedules, lines and methods for carrying out technological operations are determined.

The production line cycle is the period between the release of products (parts, assembly products) and the last operation or their launch into the first operation of the production line.

Tact calculation is carried out using such initial data as:

- production task for the year (month, shift);

- planned working time fund for the same period;

- predicted technological operational losses.

Formula for calculating the production line cycle:

r = Fd / Qout, Where

- r – production line cycle (in minutes);

- Fd – actual annual operating time of the line in the planned period (min);

- Qout – planned task for the same time period (pcs.).

Fd = Drab*dcm*Tcm*kper*krem, Where

- Dwork – number of working days per year;

- dcm – number of work shifts per day;

- Tcm – shift duration;

- kper – coefficient taking into account planned breaks;

- krem is a coefficient that takes into account the duration of planned repair work.

kper = (Tcm - Tper) / Tcm, Where

- Tper – time of planned breaks within the shift.

cream – calculated in a similar way.

In case of inevitable technological losses (planned yield of suitable parts or products), the formula for calculating cycle r is as follows:

r = Fd / Qzap, Where

- Qzap – number of products that are launched onto the production line in the planned period (pcs.):

Qzap = Qout*kzap, Where

- kzap – coefficient of launching products onto the production line. It is equal to the reciprocal of the yield coefficient of suitable products (α).

k zap = 1/α.

The yield of suitable parts as a whole along the production line is determined as the product of the yield coefficients of suitable products for all operations of the line:

α = α 1 * α 2 *…* α n

Rhythm is the number of products that a production line produces per unit of time. Rhythm is also called reverse clock size.

The amount of production line equipment is calculated for each of the operations in the technological process:

- W pi – estimated amount of equipment (workplaces) per i-th operation production line;

- t shtsh – standard piece time for the i-th operation (in minutes);

- k recordi is the coefficient of starting the part for the i-th operation.

The accepted quantity of equipment or workplaces for each operation Wpi is determined by rounding their estimated quantity Wpi to the nearest larger integer.

Using this formula, the load factor of equipment (workplaces) is calculated:

![]()

Backlog is a certain reserve in the production of materials, blanks, and assembly units. Thanks to reserves, processes on production lines proceed without interruption.

There are backlogs:

- technological;

- transport;

- reserve (insurance);

- turnover interoperational.

Synchronization is the alignment of the duration of a technological process operation in accordance with the cycle of the production line. The duration of the operation must be equal to or a multiple of the production line cycle. Synchronization methods include:

- differentiation of operations;

- concentration of operations;

- use of advanced tools and equipment;

- improving the organization of workplace servicing;

- installation of additional equipment;

- intensification of equipment operation (increase in processing modes), etc.

The highest form of continuous production process is an automated production process that combines the main features of continuous production and automated processes in it. Automated flow production and the production structure of the enterprise involve working according to the following scheme: equipment, units, devices and installations operate in automatic mode, according to a given program. Specialists monitor these processes and ensure that the work does not deviate from the scheme, and set up automated equipment.

Automation can be partial or complex. Partial automation is a process in which a production worker does not perform any technological processes. When transport and control operations are carried out during equipment maintenance, manual labor not used at all or partially used.

If we are talking about complex automated production, people do not participate in processes such as creating products, managing the technological process, transporting parts, performing control operations, and eliminating production waste. The equipment is serviced manually.

A key element of automated production is automatic production lines (APLs).

An automatic production line is a complex of automated equipment that is arranged in accordance with the sequence of technological operations. All elements of the production line are connected by an automated transport system, as well as a system automated control. The main task of nuclear submarines is to ensure the automatic conversion of raw materials or workpieces into finished products. Each automatic line has its own types of products.

A specialist working on an automatic production line sets up the equipment, controls how it works, and loads the line with workpieces. So, nuclear submarines are characterized by:

- automatic execution of operations within the technological process (human participation is not required);

- automatic movement of products between individual units of the line.

Automatic complexes, the production cycle of which is closed, are called automatic lines, connecting automatic transport and loading and unloading devices.

Automated workshops (sections) consist of automated production lines, autonomous automated complexes, automatic transport, warehouse, management systems, automatic systems quality control, etc.

The market environment today is very unstable, especially for enterprises producing products in wide range. In this regard, it is necessary to increase the flexibility (versatility) of automated production to most fully satisfy the requirements, requests and needs of customers, and quickly and economically develop the production of new products.

Nuclear submarines become the most effective in the case of mass production. Rapid turnover of goods and requirements for their low cost at good quality lead to contradictions. In particular:

- on the one hand, nuclear submarines and special equipment contribute to a significant reduction in costs;

- on the other hand, it often takes one and a half to two years to design and create such specialized equipment; this may cause it to become obsolete by the time of release.

When non-automated, that is, universal, equipment is used in production, the level of complexity of product production increases, therefore, the cost increases, which is completely unnecessary in modern market conditions. This problem can be solved by creating a flexible production system, where all its elements are combined:

- manufactured parts into processing groups;

- equipment;

- material flows (parts, blanks, products, equipment, fixtures, main and auxiliary materials);

- production processes from plan to finished product (main, auxiliary and servicing production processes are integrated);

- service, since all service processes become one;

- management, the foundations of which are computer systems, data banks, application packages, CAD, automated control systems;

- information flows to make decisions across all departments of the system on the availability and use of materials, workpieces, products, and data display tools;

- personnel, as professions are combined (designer-technologist-programmer-organizer).

It should be emphasized that the production structure of the enterprise is dynamic. Technical means, technologies, labor and management activities are improving. The structure of production is also improving, prerequisites for more intensive functioning and efficient distribution of resources appear.

The production structure of the enterprise depends on:

- industry affiliation (we are talking about the range and design features of components used in the production of materials; methods used to obtain and process workpieces; simplicity of design and manufacturability of products; type of production, level of its specialization and cooperation; composition of equipment and technological equipment ( equipment can be universal, special, non-standard, and lines can be conveyor or automatic);

- the nature of the product and methods of its production;

- volume of production of goods and their labor intensity;

- level of specialization and cooperation of the production process;

- features of buildings, structures, equipment used, materials and raw materials;

- centralized or decentralized organization of equipment maintenance, current repairs and technological equipment;

- production capabilities in as soon as possible and without large financial losses, adapt to new conditions that involve the release of new units in a changed product range;

- the nature of the production process in the main, auxiliary, secondary and auxiliary workshops.

The shopless management structure of a manufacturing enterprise contributes to more advanced management of all its departments. In this case, the management and maintenance staff is also reduced, and accordingly, production costs are reduced.

A well-built, continuously improving production structure of the enterprise contributes to the proportional relationship of all departments, improvement of technical and economic indicators: levels of specialization and cooperation, uninterrupted production process, rhythm of creation and sale of products, more productive labor activity, improvement of the quality of goods, the size of unfinished production and normalized working capital. funds, the ratio of the number of personnel employed in management and production, the feasibility of using labor and financial resources.

The production structure of companies operating in different industries has its own characteristics, which are mainly influenced by the nature of the main production.

If we take textile factories as an example, their structure is mostly technological, where individual sections specialize in specific numbers and articles of yarn. Most textile production enterprises combine all technological processes, including weaving, finishing, and spinning, on one territory. However, some perform only one or two stages of creating the finished product.

The structure of metallurgical plants is usually technological, with rolling, copra, steel, and blast furnace shops. Metallurgical plants often include sinter plants and coke plants.

The production structure of enterprises operating in different industries has one common indicator. It's about about how service and support departments are organized. A company in any industrial sector has workshops for the chief power engineer and chief mechanic, a warehouse and transport facilities. For a machine-building plant it is necessary to have a tool shop, for a textile factory - roller and shuttle workshops, which create tools for the main production.

Determining and organizing the structure of production is a very responsible task, which must be solved both when creating new and when changing existing companies.

Below are ways in which the overall production structure of an enterprise can be improved:

- organization of main and auxiliary workshops and areas in a rational ratio;

- compliance with the necessary proportions between sections of the enterprise;

- expansion of sites and workshops;

- continuous rationalization of the production structure;

- search and implementation of more advanced principles for building workshops;

- merging departments, creating powerful associations of industry and research and production based on concentration of production;

- a change in production direction, that is, the nature of the manufacture of goods, specialization and cooperation, the development of combining production, the desire to create structural and technological homogeneity of products through extensive unification and standardization; formation of a shopless management structure for a production enterprise. Due to the consolidation of companies and workshops, the introduction of high-performance equipment is carried out in more on a global scale. At the same time, technologies and organization of the production process are continuously improving.

When ways to improve workshops and divisions are identified, the structure of the production department of the enterprise and the entire company as a whole improves, and work efficiency increases.

The main, auxiliary and service workshops must be in a rational ratio in order to increase the share of the main workshops in terms of the number of employees, the price of fixed assets and the size of the territories in which production is located. With rational planning, the company's master plan is sure to be improved.

Enterprises should wisely use available opportunities, resources, and market conditions in order to effectively plan their production. If a company manages to develop a plan that is optimal from the perspective of constantly changing market conditions, it has a greater chance of surviving and not losing ground in the external economic environment. In this regard, it is necessary to pay increased attention to material on planning the production process.

The master plan is the most important component of the project of a company operating in the industrial sector. IN master plan Issues related to the improvement and planning of the territory, how buildings and structures will be located, where transport communications and utility networks should be located, how economic and consumer services systems should be organized, and what place the enterprise should occupy in an industrial hub or district are comprehensively resolved.

The master plan must meet certain high requirements. Here are the main ones:

- The areas are located along the production process - warehouses where raw materials and semi-finished products are stored; Next come processing and assembly shops, then warehouses for finished products.

- Auxiliary areas and farms are located in close proximity to the main production workshops.

- Railway tracks are rationally arranged within the organization: they are connected to warehouses where materials, raw materials and semi-finished products are stored; to warehouses of finished products, where products are additionally equipped with various parts, preserved, loaded and sent for sale.

- Raw materials, materials, and finished products are transported in the shortest possible time and with the greatest accuracy.

- Counter and return flows in and outside the premises are excluded.

- The organization’s external communications are well located and connected to highways, utility networks and railway tracks.

- The blocks house laboratories (measurement, chemical, X-ray testing, ultrasound) and workshops that thermally process protective coatings of parts and finished products.